The rise in heart valve disease and other cardiovascular conditions has led to a growing demand for minimally invasive devices and technologies. In addition, medical devices need to meet specific tissue response and durability criteria for the biomedical structures to elicit proper biologic responses. This means that medical devices need to be small and flexible to enable minimally invasive surgeries while also being strong and durable so they can last for the full life of the patient. The use of ultra-high molecular weight polyethylene fibers like Honeywell Spectra® UF BIO can play a significant and useful role in the development of biocompatible medical devices, particularly in the field of cardiovascular applications such as heart valves.

What is Honeywell Spectra® UF BIO Fiber

Spectra® UF BIO Fiber is a product portfolio that falls under the Honeywell medical grade fibers offering that is known as Spectra® MG BIO Fibers. All of the products within the Spectra MG fiber portfolio are 100% ultra-high molecular weight polyethylene (UHMWPE) fibers. These fibers are manufactured through a unique gel spinning process — the first of its kind. It’s one of the world’s strongest and lightest fibers, enabling the design of medical devices that have higher surgical accuracy rates, faster recoveries, and better patient outcomes.

Ultra-fine UHMWPE fiber like Spectra MG is 15 times stronger than steel by weight, 40% stronger than aramids on a weight-by-weight basis and three times stronger than polyester on a volume basis. It also offers high pliability, low elongation and a low coefficient of friction that allow the development of stronger, lower- profile devices.

What makes Honeywell Spectra UF BIO Fibers ideal for use in medical device applications?

Strong, thin fiber ideal for lower profile devices Smaller-profile medical devices are important especially for cardiovascular patients. They help facilitate less invasive procedures that reduce patient discomfort and recovery time. Honeywell’s Spectra UF BIO offers a stronger, thinner solution as compared to traditional materials such as nylon and polyester making it ideal for even the smallest cardiovascular devices. Available from 100 denier down to the 10 dtex, this UHMWPE fiber allows for smaller devices that can access smaller anatomical structures other devices can’t reach.

Designed for a lifetime of durability

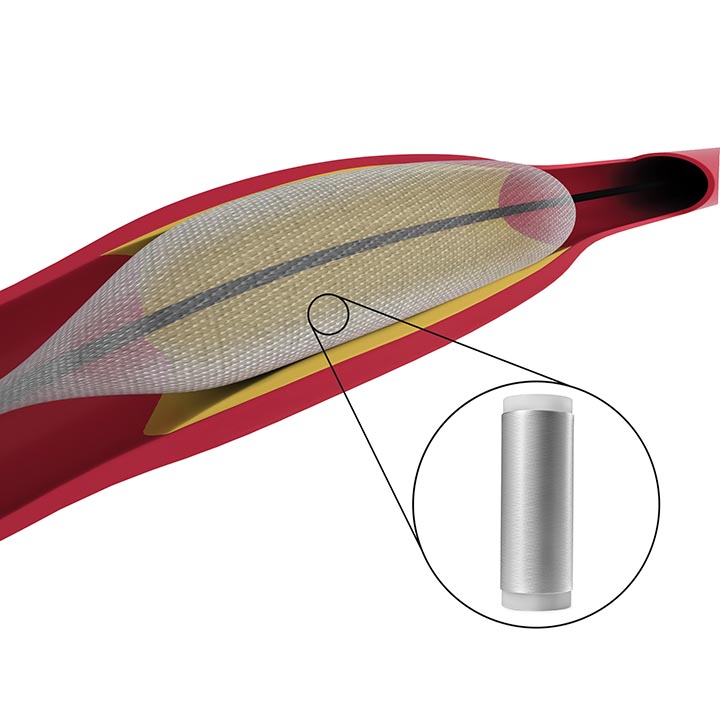

Spectra UF BIO can be shaped into a variety of textile constructions, including braids, woven shapes and knits to enhance the design of implantable cardiovascular devices. Spectra UF BIO is biocompatible, chemically inert and offers superior resistance to fatigue and abrasion compared to polyester – extending the life of in-body devices compared to those using a polyester fiber. This creates the potential for improved patient quality of life by reducing the need for revision surgeries in the future. Spectra UF BIO also has a lower coefficient of friction than polyester, resulting in easier transfer through tissue and enabling lower levels of patient inflammation after surgery.

Other applications for Spectra UF BIO

Use of Spectra UF BIO in cardiovascular is just one of the many key areas that benefit from the use of this small, yet strong fiber. Spectra UF BIO can also be used in orthopedics, surgical robotics, and more.

Backed by Honeywell’s commitment, expertise, and support

Customers have trusted Honeywell to solve their greatest challenges for more than a century, and we’re committed to helping innovate with you. Our lineup of medical-grade fibers is produced at our world-class U.S. manufacturing sites and is backed by our strong technical support and expertise in UHMWPE.

Scan for more information: