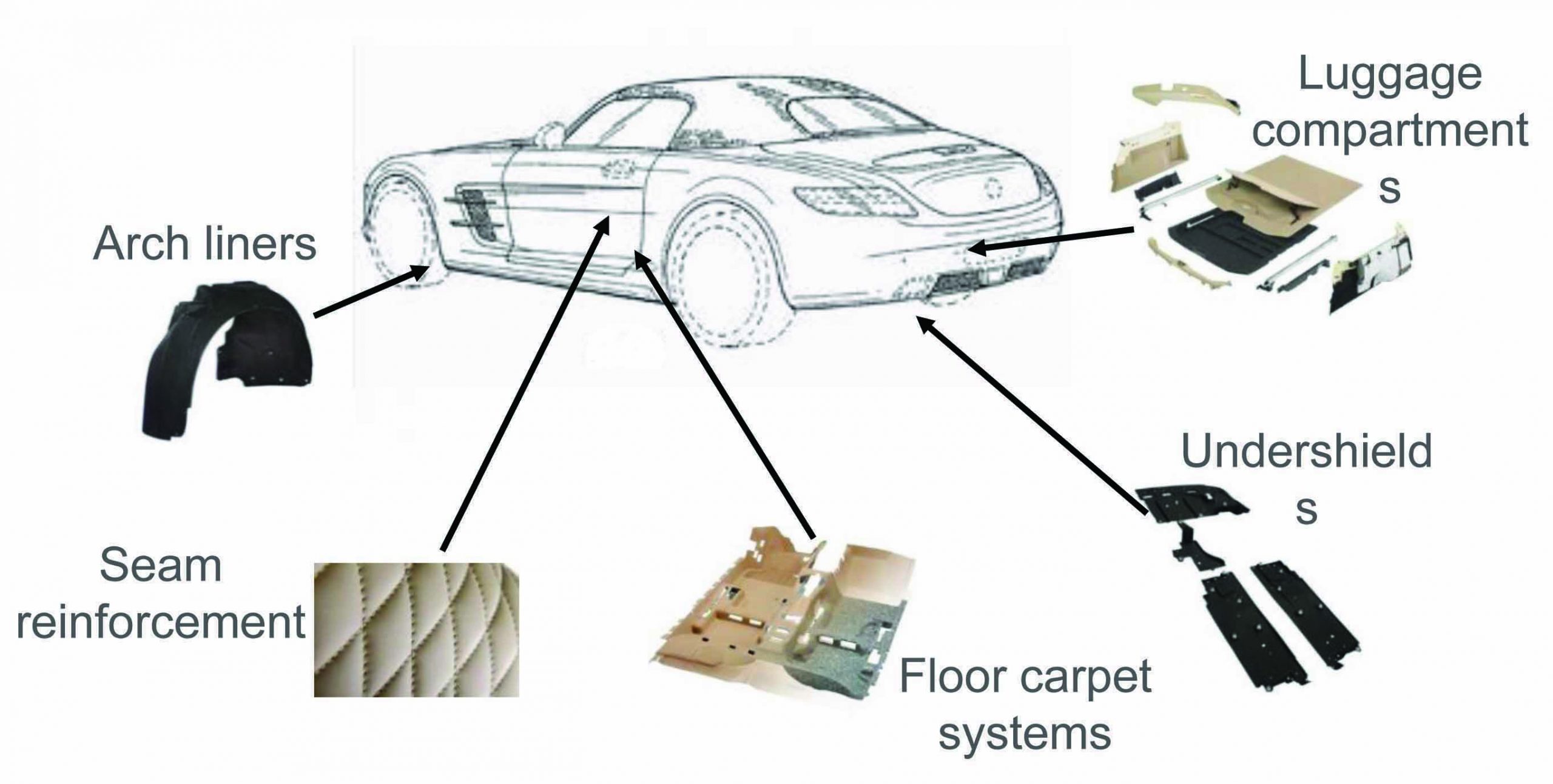

Figure 1: Typical PP fiber applications in the automotive market.

Polypropylene (PP) staple fibers are used in many different applications, such as automotive, carpets and floorcoverings, geotextiles, apparel, sanitary and hygiene, and technical applications.

In the automotive sector, for example, end-uses include luggage compartments, undershields, floor carpet systems, wheel arch liners and seam reinforcement. Currently, around 20 kg of various fibers are used per vehicle – and this figure is increasing.

Speaking at the 54th Man-Made Fibers Congress held last year in Dornbirn, Austria, Hermann Linsbauer of IFG Asota, Austria, described research undertaken with the Transfercenter für Kunstofftechnik of Wels, Austria, on developing PP fibers for automotive composite applications.

The composite nonwoven materials comprised commingled fibers, typically PP with a melt binder, and glass fiber reinforcement. These exhibited a specific porosity, depending on the application and are often constructed from different layers.

The work aimed to develop PP binder fibers for automotive composite end-uses in combination with glass fibers and flax fibers.

In particular, it was hypothesized that improved interaction between the fibers would result in improved composite properties. The study also aimed to understand the different influences on composite properties and to develop the best solutions for specific applications.

The binder fibers were PP staple fibers (7 dtex, 60 mm), such as Asota E 6101, with and without additives; the reinforcements were glass fibers (14 μm, 60-90 mm) and flax fibers (non-commercial, cut from a yarn, 60-90 mm).

Staple fiber production was undertaken on a new high-performance line with triple drawing, which was installed at IFG Asota’s site in Linz.

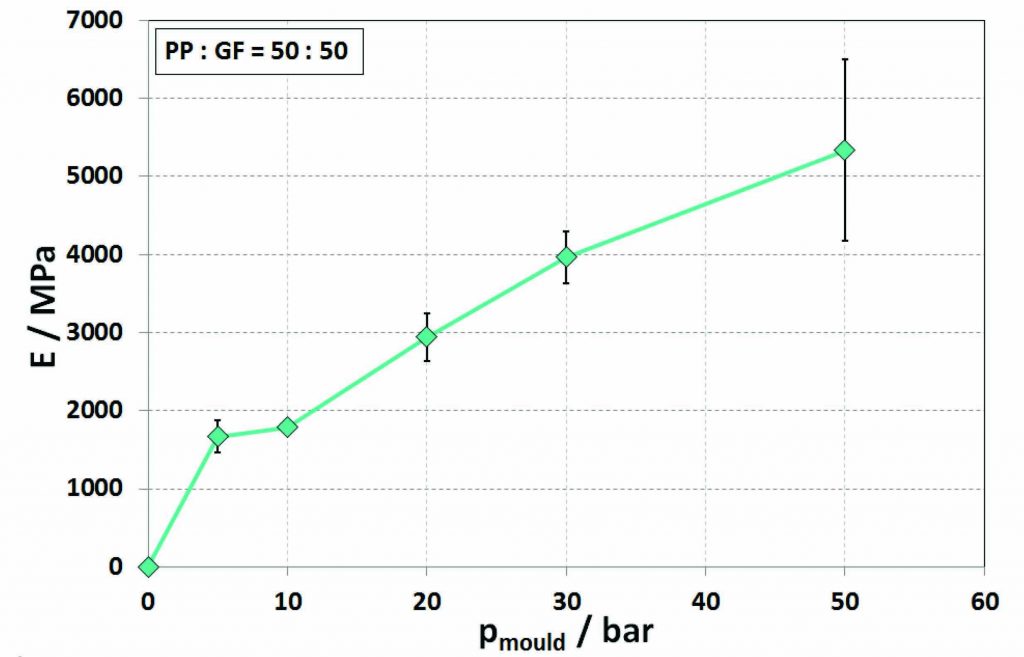

As an example, a 50/50 blend of PP and glass fiber was formed (needlefelt) into a nonwoven with a density of around 400 g/m2, and then processed under heat (190°C) and pressure (5-50 bar) to form strip samples for subsequent testing.

It was found that porosity/compaction in the process plays a major role. In general, with increasing pressure the composite properties were enhanced owing to lower porosity (increased contact).

Porosity had an influence on elastic modulus and tensile strength; other influences were fiber and damage.

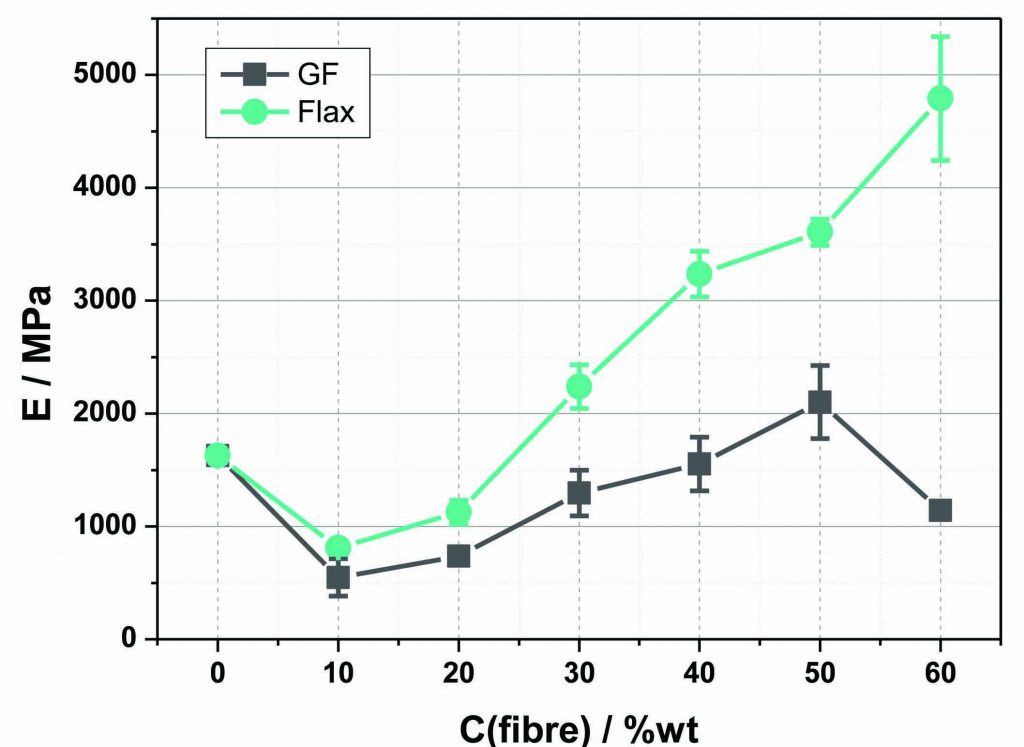

It was also discovered that the reinforcement fiber type influenced the mechanical properties – flax is less prone to breakage than glass fiber and exhibits finer fibers. And owing to the finer fibrils of flax, wetting is better and porosity is lower.

Further, through the addition of modifiers, the composite properties can be greatly enhanced, thus resulting in a high lightweight potential. It was found that different modifiers result in different improvements, so the optimum compound can be chosen for each specific application.

Improvements can be up to 50% and more, depending on the modifier used and the concentration.

As part of the research, IFG Asota produced composites from both standard and tailored PP fiber in a 50/50 blend of glass fiber/PP fleece (700 g/m2), which were compacted using a hot press to comparable porosity and then tested.

Microscopic analysis showed a visible difference between the two types of PP fiber, and it was also demonstrated that improved adhesion of composite binder fibers improved the composite properties.

With typical automotive fleeces of around 1,000 g/m2, the use of tailored fibers resulted in a 20% increase in elastic modulus and around 20% reduction in material used. Additionally, the thinner design can result in faster consolidation cycles and improved processing.

In conclusion, the study showed that porosity/compaction in the production process plays a major role, as well as the formulation chosen. Further, via the formulation (i.e., through the addition of modifiers), the properties can be greatly enhanced, thus resulting in a high lightweight potential.

For more information contact:

IFG Asota GmbH

Tel: +43 732 69850

Fax: +43 732 6985 5526

Email: office@ifgasota.com

Website: www.ifgasota.com