Ph.D., 2021

University of Limerick

School of Engineering, Bernal Institute

Research Group:

Maurice Collins group

Professor/Advisor: Maurice Collins, Ph.D.

The Bernal Institute hosts a multidisciplinary team of world-leading materials scientists and engineers at University of Limerick. The composite cluster aims to develop of new carbon fiber materials from sustainable resources (lignin) for their use in composites with thermoplastic matrices from natural, sustainable supplies.

Dr. Beaucamp Mc Loughlin completed her Material Science master’s degree at the University of Limerick, with an emphasis on the surface properties of materials. She has a degree in Physics, so the study of surface interactions was a natural area of study. After graduating from her master’s degree program, Dr. Beaucamp joined Dr. Maurice Collins’ group at the Bernal Institute. Dr. Collins was awarded a H2020 grant on the development of sustainable carbon fibers as part of the project LIBRE, and Dr. Beaucamp was honored to be offered a Ph.D. studentship on that project, studying the replacement of oil-based materials by sustainable materials, which she believes is one of the greatest challenges that industry will have to overcome in the coming decades.

Research overview

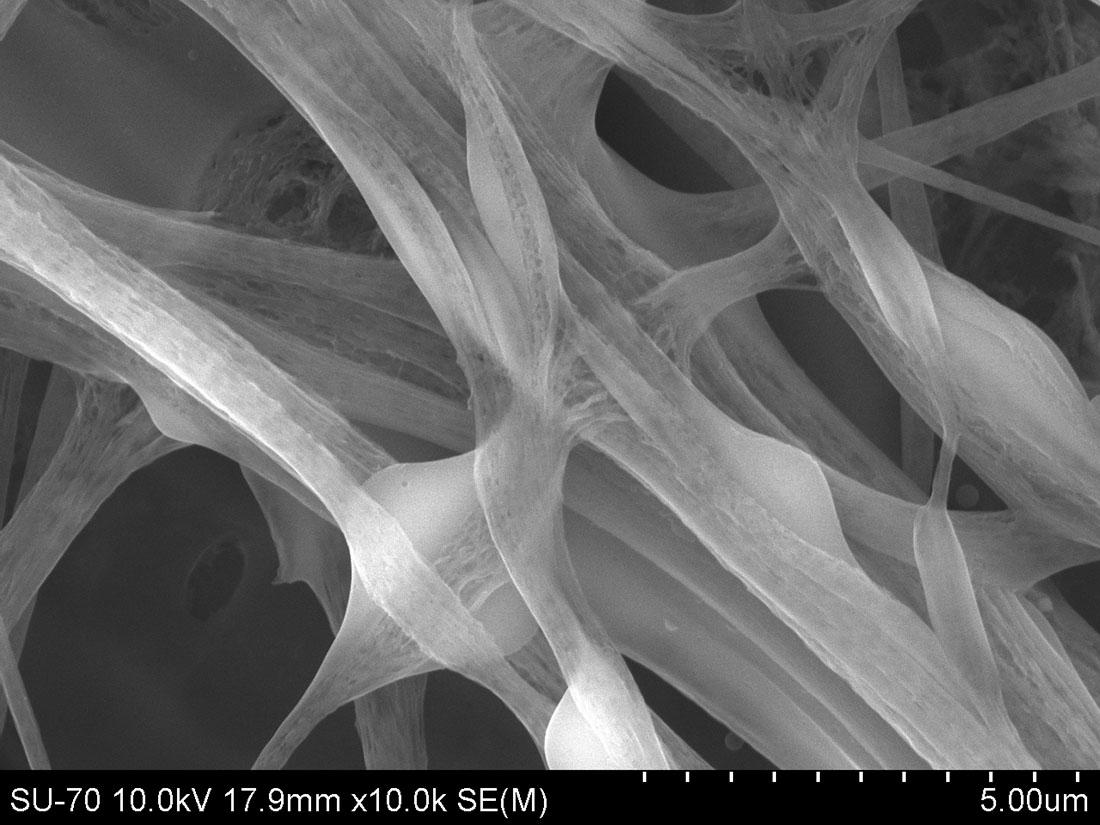

The development of high-value technologies from waste resources is critical to tackle the depletion of natural resources. Lignin is a renewable, low-cost by-product of the paper industry. Its unique aromatic structure is key to a sustainable production of carbon fibers and carbon nanofibers. These materials have applications in high-value industries such as aerospace, automotive and leisure, as well as energy storage and production, water treatment systems and biosensing.

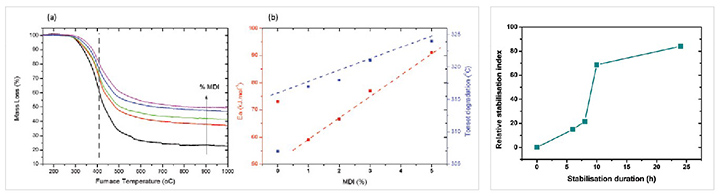

Her work investigates the relationship between the lignin chemical structure and its processing properties, both alone and in a polymer blend. Two hardwood lignins are investigated, an as received organosolv and a hydroxy propylated kraft lignin. The effect of melt extrusion is studied in detail with regards to the chemical modifications sustained by both lignin during processing. A successful blend was developed with thermoplastic poly(urethane) (TPU) that showed strong compatibility and thermal behavior. The influence of modifications of the lignin chemical structure prior to extrusion was studied in detail, to improve the blendability of lignin with bio-based poly(ethylene terephthalate) and optimize the carbon phase of the obtained carbon fibers. A crosslinker was added to the lignin-TPU blend to improve the efficiency of the thermo-stabilization phase with regards to crosslinking behavior and carbon yield. Sustainable lignin-based carbon nanofibers were used to develop a enzymatic glucose sensor. The porosity of the lignin-PLA-based carbon nanofibers was critical to the immobilization of glucose oxidase for sensing.

A successful blend was developed with thermoplastic poly(urethane) (TPU) that showed strong compatibility and thermal behavior. The influence of modifications of the lignin chemical structure prior to extrusion was studied in detail, to improve the blendability of lignin with bio-based poly(ethylene terephthalate) and optimize the carbon phase of the obtained carbon fibers.

Career goals

Dr. Beaucamp Mc Loughlin plans to continue her work on the development of sustainable composites from lignin and to apply her knowledge of this unique and versatile material. To offer this waste material new high-value streams and potential industrial output would help resolve the current tie that links technology to oil-based materials. Dr. Beaucamp Mc Loughlin aims to combine her passion, knowledge and experience to tackle sustainable development goals and drive change. As a parent, Dr. Beaucamp Mc Loughlin really hopes to make a difference in this field. In the near future, she will continue to work on research and development with both academic and industrial partners, to keep a foot in reality while making progress in the field of sustainable materials. In the next 5-10 years, Dr. Beaucamp Mc Loughlin aims to be a well-respected member of the field, hoping to lead academic and industrial partnerships to provide new solutions to the replacement of oil as a carbon material precursor.

For details on how to submit yourself or a student you know for consideration as a “Student Spotlight” in IFN, contact Matt Migliore at mmigliore@inda.media or +1 919.459.3754.