Anthony John Galante is pursuing a Ph.D. in Industrial Engineering at the University of Pittsburgh, where he is conducting research on microbe repellent surfaces at the Lab for Advanced Materials in Pittsburgh (LAMP). His research focuses on the application of surfaces with different functionalities such as self-cleaning, stain-resistance, bacteria-repellency and virus repellency.

4th Year Ph.D. Student

University of Pittsburgh

Swanson School of Engineering/Department of Industrial Engineering

Lab for Advanced Materials in Pittsburgh (LAMP)

Galante’s interest in research began during a summer undergraduate research opportunity at Pitt. He started working for the LAMP and became fascinated by the beauty of superhydrophobic surfaces. He found an interest in the application of superhydrophobic surfaces but learned that a significant challenge in realizing these surfaces in industrial applications is their poor durability. Galante began working on nanotechnology techniques to render repellent surfaces that are mechanically durable, as well as textile surfaces that are wash-stable.

He discovered a method to coat nonwoven microfiber textiles to not only be superhydrophobic, but also to have mechanical durability and wash stability. He thought that working with nonwoven textiles would have great potential for future applications, and his research developed into exploring the possibility of repelling other liquids such as oil and blood, as well as repelling bacteria, proteins and viruses.

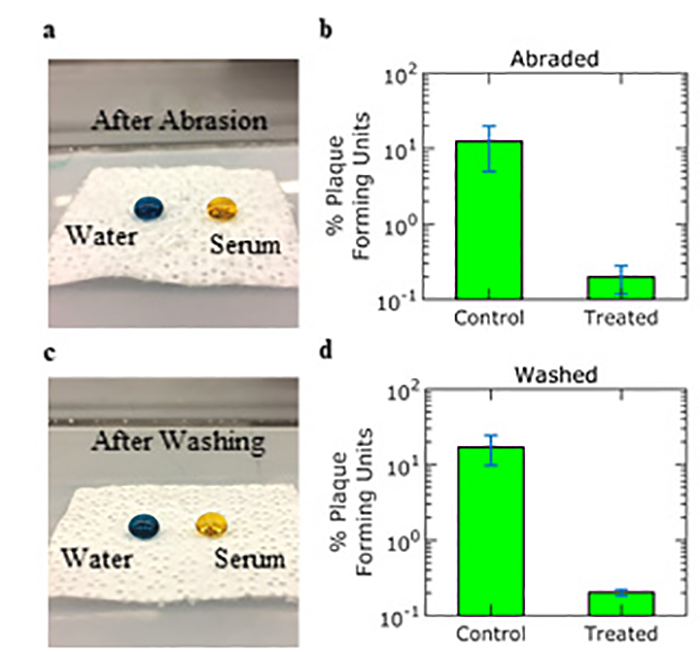

The multiple layers allow the abraded areas to wear away in a manner that leaves a similar surface underneath, to maintain repellency properties. The liquid and virus repellency, along with the durability of these functionalities, are compelling for use in reusable medical textiles.

Research overview

Galante’s research consists of fabricating and testing the performance of multifunctional surfaces. Functionalities that he has worked with include virus-repellency, bacteria repellency, self-cleaning and stain-resistance. These surface functionalities are highly desirable in various industries from healthcare, textiles, to household appliances. Galante’s experience includes fabricating new surface treatments, characterizing surface properties and testing for repellency performance, mechanical durability, and wash stability.

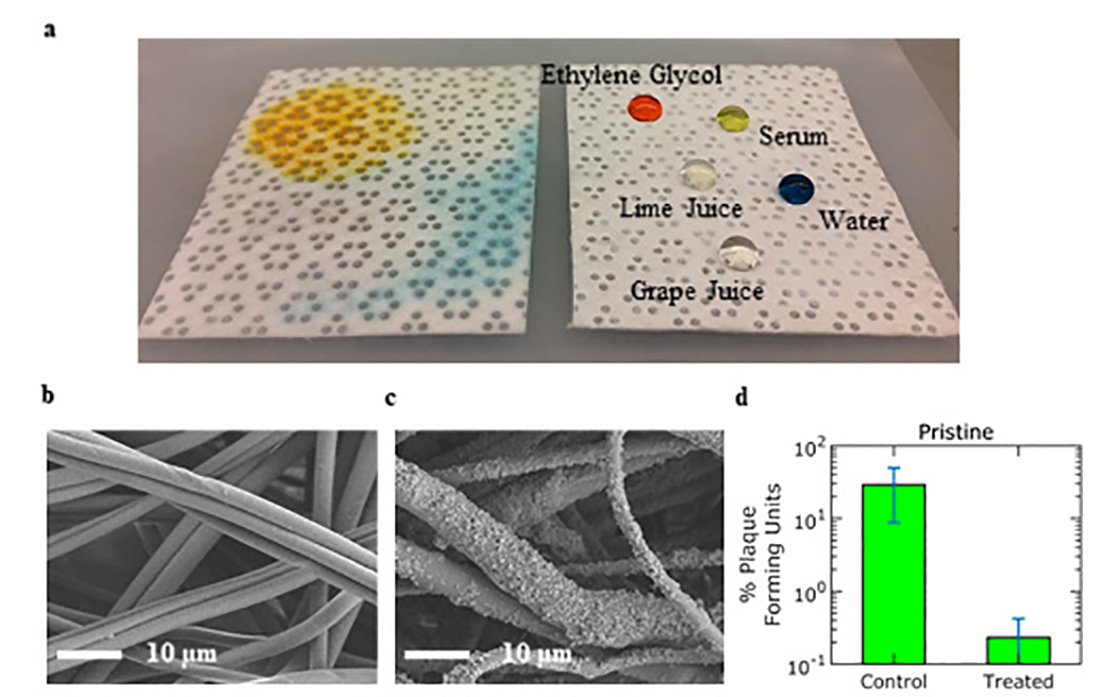

Galante’s recent work was published in ACS Applied Materials & Interfaces and demonstrates the first virus repellent or antivirofouling surface on a nonwoven textile. Treated nonwoven textiles reduce the attachment of two different types of adenovirus that cause respiratory lung infections. Also, the textile is superhemophobic, or serum-repelling, and superhydrophobic, or water-repelling. This is ideal since treated textiles not only repel viruses but also the liquid medium of viruses, which are commonly body fluids such as blood and saliva. The treatment consists of multiple layers of nonwoven polypropylene (PP) microfibers and polytetrafluoroethylene (PTFE) nanoparticles. The multiple layers of low surface energy polymer microfibers and nanoparticles traps air between the textile and the liquid medium, which significantly reduces the amount of surface area in contact with the liquid. The treated textile reduces the amount of contact area between the textile and virus particles and thus reduces virus adhesion. These findings are important for improving personal protective equipment to reduce the spread of infectious disease through surfaces.

The main highlight is that the treatment maintains liquid and virus repellency properties after harsh mechanical abrasion from a Scotchbrite scrub or ultrasonic washing in liquid detergent. The multiple layers allow the abraded areas to wear away in a manner that leaves a similar surface underneath, to maintain repellency properties. The liquid and virus repellency, along with the durability of these functionalities, are compelling for use in reusable medical textiles.

Galante’s other works focus on bacteria repellent and self-cleaning polymers, antibacterial textiles, and oil repellent 3D printed structures.

Career goals

Galante’s near-term plans including publishing more journal articles on his research and graduating from the University of Pittsburgh with a Ph.D. in Industrial Engineering. Afterwards, he hopes to work for a coating or device company to help introduce future applications to the world. His main goal is to be able to see the applications he helped develop be useful for society. One day, he wants to lead a research team on innovations in device, coating or textile technology.