The Soft Functional Materials Lab @ VCU is motivated to apply fundamental science to solving challenging and practical problems. The lab focuses on the processing and characterization of soft functional materials with applications in biomedical and environmental engineering. Lab members work at the interface of polymer science, nanotechnology and biotechnology, to design, process, and apply novel multifunctional materials.

Jimmy Nguyen became interested in the lab and research when he realized the vast applications of the studies being done. He felt that it was research with a purpose that would open doors to new technology capable of pushing innovation forward for fields of medicine, sensors, entertainment and more. He joined the lab as a freshman to pursue research in liquid crystal formulations and thermochromic fiber processing.

Together, Jimmy and Ratib are working on a project to develop a multifunctional temperature-responsive textile through the incorporation of cholesterol-based liquid crystals into polymer fibers.

Ratib Stwodah was infatuated with chemistry during his high school years, and he could hold his own in math. He planned to become a chemist until his brother advised him to look into chemical engineering. Later, he researched the VCU program and decided to take a leap of faith and he hasn’t looked back since. Christina Tang, Ph.D., grabbed his attention during the freshman year by presenting on nonwoven fibers, and he joined the lab to pursue research in functionalized nonwoven fibers.

Research overview

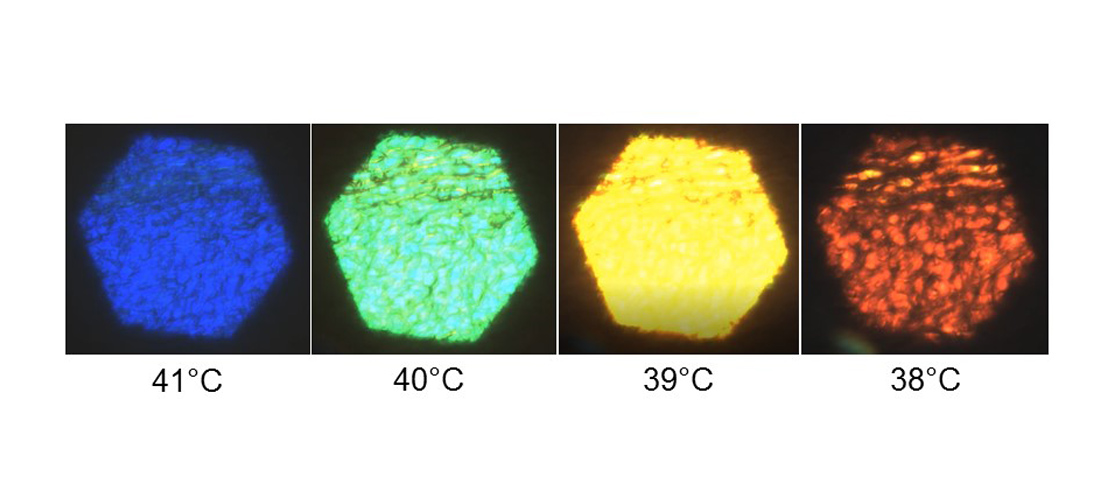

Together, Jimmy and Ratib are working on a project to develop a multifunctional temperature-responsive textile through the incorporation of cholesterol-based liquid crystals into polymer fibers. Cholesteryl ester liquid crystals exhibit thermochromic properties related to the existence of a twisted nematic phase.

Ternary mixtures of cholesteryl benzoate (CB), cholesteryl pelargonate (CP), and cholesteryl oleyl carbonate (COC) are formulated to achieve thermochromic behavior. To date, Jimmy and Ratib have formulated cholesteryl ester liquid crystals with various transition temperatures between 24 C and 36 C and characterized their thermochromic behavior with ultraviolet reflectance and polarized light microscopy.

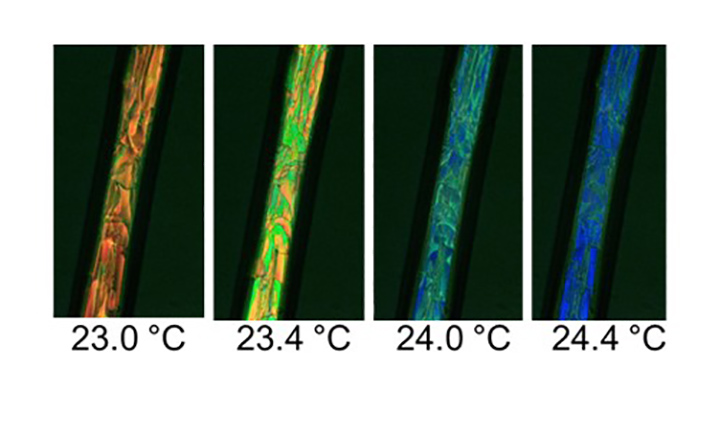

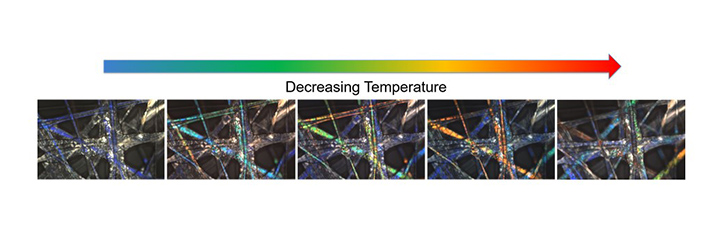

Currently, Jimmy and Ratib are incorporating liquid crystals into polymer fibers via blend spinning and coaxial spinning to determine the effect of fiber processing on the thermochromic properties of the liquid crystal. The fiber structure is characterized by scanning electron microscopy and the thermochromic properties of the liquid crystal are evaluated using polarized light microscopy.

For blend electrospinning, the tandem found that intermolecular interactions seem to be important in facilitating fiber formation since addition of the liquid crystal (LC) facilitates fiber formation. However, not all blend fibers are thermochromic. The functional properties depend on the polymer and processing conditions. Coaxially electrospinning with LC and solvent in the core preserves the thermochromic properties of the LC so that thermochromic fibers are achieved.

Overall processing conditions that promote phase separation between the liquid crystal and polymer are promising for achieving thermochromic properties. These results are compelling because they demonstrate a process-function relationship for this class of fibers. Products made from such fibers could have many potential applications, such as clothing or sheets with increased personal comfort, medical textiles, or camouflage.

Career goals

While finishing his undergraduate studies, Jimmy plans to continue working on developing his knowledge of research/application, applying what he has been learning and determining issues he is motivated to tackle in the real world. Post graduation, he plans to continue to gain experience working in industry before going back to pursue a higher degree to refine his technical and research skills. Jimmy aims to combine his passion for creating a more just society and technical background as an engineer to tackle societal problems through technical analysis, advocacy and research. Ultimately, he strives to inspire others to make a difference in society through engineering and better the relationship between engineering and social work to drive change.

Ratib’s first project in the lab involved using fiber processing as an alternative to freeze-drying nanomedicines, which could be valuable in avoiding cold-chain storage. This sparked his interest in manufacturing in the pharmaceutical sector. In the near term, he plans on pursuing a process engineering or manufacturing science role at a biopharmaceutical manufacturing facility. In biopharma, he looks forward to fulfilling his desire to help people while pursuing his passion for technical research. In 5-10 years, he is aiming to become an associate director (if not a director) of a technical team within a biopharmaceutical company.