Reifenhäuser Reicofil presented its solutions for nonwovens production at INDEX, Oct. 19-22, in Geneva, Switzerland. Under the slogan “Living Nonwovens,” the nonwoven line specialist showcased solutions for the production of sustainable nonwovens for a wide range of applications.

“Nonwovens often accompany us from the first to the last day of our lives. In diapers, face masks or air filters, the material contributes to our well-being, safety, and comfort. Nonwovens are close to our skin so they deserve only the highest quality. This is what we stand for, this is what we live for,” explains Markus Müller, Sales Director at Reifenhäuser Reicofil.

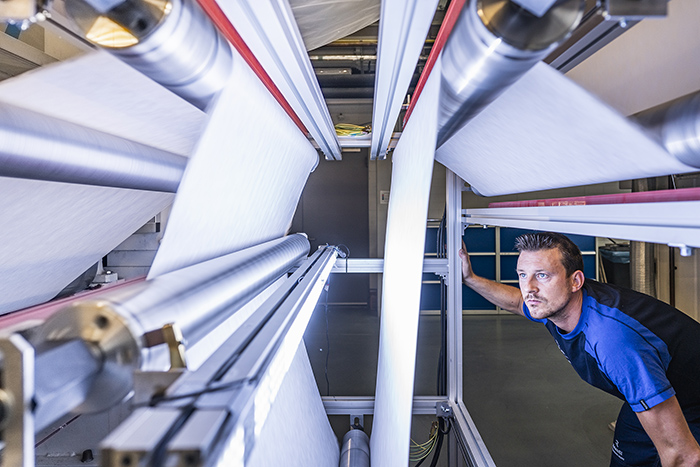

The Reicofil 5x line series is specialized in this application and achieves fabric weights of 8 gsm (grams per square meter) or even less through efficient downgauging, even on 1000 m/min composite lines containing three spunbond beams.

In addition, Reicofil customers can reduce the use of fossil raw materials on request by processing biobased raw materials as an ecological alternative – for example for diapers. The topsheet material, made of bulky, soft, and industrially compostable high-loft nonwovens, meets maximum hygiene requirements at the same time.

For industrial applications, high-strength nonwovens can be processed with Reicofil technology, even from up to 90% PET flakes from post-consumer waste.

In the medical sector, Reicofil also exhibited its solutions for high-barrier medical protective clothing. Reicofil is capable of generating materials with filtration efficiencies of up to 99% (N99 / FFP3 standard), minimum quality fluctuations, and extremely high line availability at the same time.