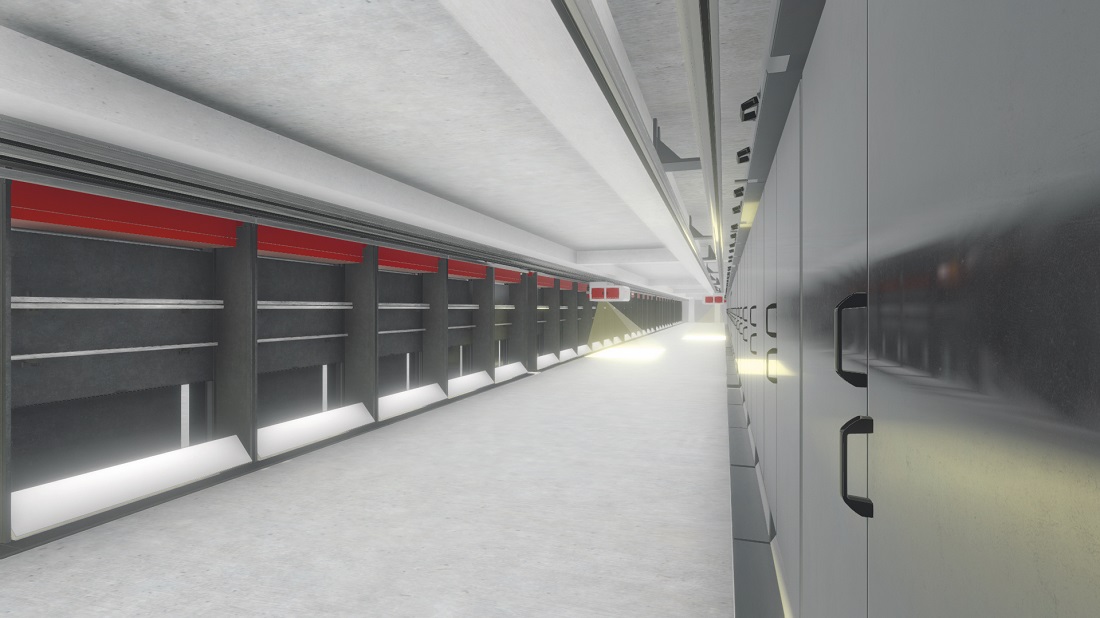

Oerlikon Barmag’s first wiping robot has now been operating in India since the end of 2019. The even wiping process provides reduced yarn break rates and higher full package rates. Regular wiping (cleaning) of the spin packs is important for process stability and yarn quality. The wiping robot operates in a cross-line manner. The cleaning quality remains constant, reducing the impact of the wiping on both the spinning plant process stability and on the yarn data of the spun yarn.

Manufacturers who have implemented the wiping robot have found that the yarn break rate has fallen by almost 30%, running time breaks have decreased by 10% and string-up breaks by 40%. Full package rates have risen by 3% and waste rates have fallen by 0.2%.