In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant to our industry from manmade to natural to bio-based fibers, innovations in nonwoven, woven, braided and technical textiles, technologies for additives, bonding, coatings and polymers, and applications from apparel to hygiene to transportation, and more. Here we will post news stories relevant to textile fibers and their downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Matt Migliore at mmigliore@inda.media.

Most recent update: September 30, 2020

Fitesa continues acquisition push, adds Fiber Dynamics Inc. to list of recent purchases

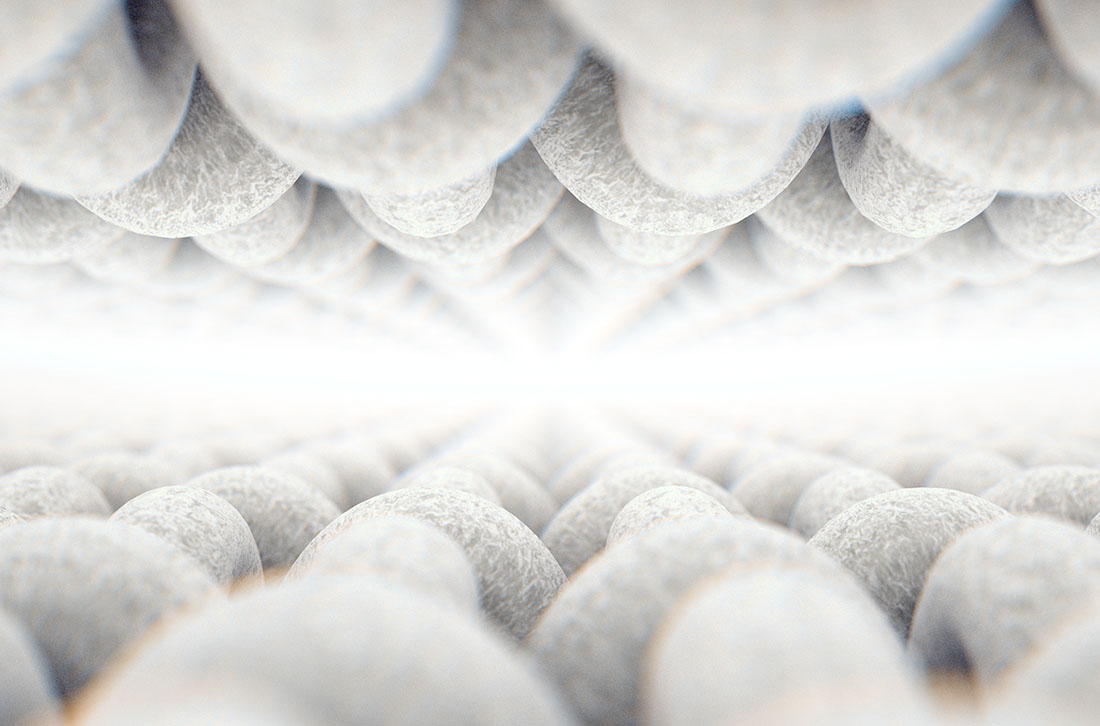

Fitesa has acquired the assets of Fiber Dynamics Inc., (FDI) a producer of Engineered Nonwovens. Located in High Point, North Carolina, FDI manufactures meltblown and carded nonwovens for disinfectant wipes, filtration, face masks, automotive, medical, hygiene and other industrial applications.

The acquisition is expected to strengthen Fitesa’s asset base to serve the healthcare market, especially the wipes segment. In addition, it will increase the company’s technical expertise with the hiring of trained and experienced employees.

This is Fitesa’s third acquisition in 2020. In February, the company acquired Freudenberg Hygiene Brazil. In August, Fitesa announced the agreement to purchase Tredegar Personal Care, which is expected to close during the fourth quarter of 2020.

Source: fitesa.com

Nonwovens by Design now offering quality management services

Nonwovens by Design, LLC, introduced new services in Quality Management Systems for the nonwovens industry. To provide these services announced the addition of two new associates, Thomas Connor, ASQ Certified Quality Auditor, Certified Manager of Quality/Organizational Excellence and Robert Lightsey, Six Sigma Black Belt, ASQ Certified Quality Engineer, ASQ Certified Quality Auditor.

NBD will now offer a complete review of quality systems including compliance to ISO/AS/IATF quality standards. This service will help companies that are trying to control overhead costs by providing Quality Systems Engineering activities that may not be available in-house.

Services offered, include Quality Manuals, Document Control, Control of Records Quality Planning and Management Reviews, Quality System Training, Design and Development Processes, Customer Communication, Purchasing/Materials Control, Quality Assurance Systems, Six Sigma, FMEA, Cost of Quality, Control Plans and Internal auditing.

Source: nonwovensbydesign.com

Association of Italian Textile Machinery Manufacturers announce digital certification program

ACIMIT, the Association of Italian Textile Machinery Manufacturers, launched a project aimed at defining a form of digital certification, which can be used by Italian manufacturers to certify the ease of integration of their machinery into the production systems of their textile customers.

The first step in this project has been the elaboration of a shared reference vocabulary for Italian textile machinery manufacturers, which resulted in the creation of a conceptual model of machine and process production management data that can be useful for textile manufacturers in identifying and calculating related productive KPIs (Key Performance Indicators). This model was developed by the Manufacturing Group of the School of Management of Politecnico di Milano, under the scientific guidance of prof. Marco Taisch, an international expert on digital transformation processes in the manufacturing sector, and within the bounds of the Industry 4.0 paradigm, supported by researcher Elisa Negri.

As for the long term, the project aims to build customer loyalty, thanks to a common vision of machine data and an easier and more uniform integration of information derived from the machinery of different manufacturers in the operating systems of client companies. All this will be rendered concrete in the creation of the ACIMIT Digital Label, a digital certification of adherence for member companies applying this data model.

Source: acimit.it

EDANA’s virtual OUTLOOK event attracts more than 150 delegates

Held from 23-25 September, EDANA’s OUTLOOK moved to an online edition for the first time, allowing participants to engage virtually, through conference presentations, live Q&A and live interaction via Whova. The conference, which attracted more than 150 delegates from across the nonwovens and related industries, examined emerging global drivers, market trends, sustainability initiatives and new product developments over three days.

The 19th edition of OUTLOOK opened with a keynote speech on “Geopolitical scenarios shaping a post-COVID 19 world” from Jeffrey Saunders and Job Henning of Nordic Foresight. A session dedicated to global perspectives followed with overviews of regional market drivers and trade flows. The day closed with a presentation of an upcoming EDANA communications campaign on the benefit of nonwoven materials. Day 2 of the conference opened with an insightful presentation from Per Brandberg of Euromonitor on the global outlook for the disposable hygiene sector. The rest of the second day focused on an examination of the challenges and opportunities of sustainability and supply in the hygiene sector with specific reference to PPE and face masks. The final day focused on innovation and sustainability in our sector, opening with a “realistic review of post-COVID energy and environmental plans and expectations” by Samuel Furfari, Professor in Energy Geopolitics of the Free University of Brussels.

The next edition of OUTLOOK™ is scheduled to be held in Lisbon in April 2021.

Source: edana.org

Lindner Recyclingtech doubles capacity with new headquarters

Lindner celebrated a groundbreaking ceremony for its new factory premises in Spittal/Drau, Austria. The new site covers 45,000 square metres. In addition to a state-of-the-art manufacturing facility, the new headquarters will become an international Centre of Excellence for waste recovery and recycling – in keeping with its circular economy concept.

When the Lindner machine factory opened its doors in the 1940s, the company manufactured sawmill equipment. The big transformation happened in the late 80s and the company was one of the first started to delve into shredding and waste processing – Lindner Recyclingtech was born. Today, 72 years later, recycling and the sustainable use of resources are among the pressing issues of our time and the Spittal-based family business is one of the world’s leading companies when it comes to turning waste into a valuable resource.

Besides a robot-assisted manufacturing facility and a modern logistics center, an academy focusing on recycling technology will also be hosted on-site.

Source: lindner.com

Lenzing, Hof University open nonwoven development center in Germany

Lenzing Group, a manufacturer of wood-based cellulosic specialty fibers, and Hof University opened a new Nonwoven Development Center (VEZ). As a strategic partner, Lenzing has access to a state-of-the-art development line at Hof’s campus in Münchberg, Germany. Lenzing said this partnership offers new opportunities for sustainable fiber and nonwoven innovations for a wide range of applications including hygiene, body care and medical.

The VEZ was completed according to schedule in September 2020, after Lenzing and the University of Hof signed a cooperation agreement for its use in 2019. With the spunlace (hydroentangled) pilot plant at the VEZ, Lenzing will support customers and partners in the development and marketing of new nonwoven applications.

Source: lenzing.com

Techtextil and Texprocess 2021 to feature hybrid — in-person & virtual — program … Events will also co-locate with Heimtextil for first time

Techtextil and Texprocess, two leading international trade fairs for technical textiles and nonwovens and the processing of textile and flexible materials, have announced a variety of changes for its 2021 event, including supplementary digital features, a comprehensive hygiene and safety concept, new claims and a move to new exhibition halls.

International suppliers of technical textiles and nonwovens, as well as machines for processing textile and flexible materials, will once again get together in Frankfurt am Main for Techtextil and Texprocess from 4-7 May 2021. Against the background of the worldwide COVID-19 pandemic, the organizers, Messe Frankfurt, are optimistic about the prospects for the coming events.

Techtextil and Texprocess will further sharpen their profiles with reoriented communication measures for the coming fairs. In the first stage, both events are being given new subtitles. From now on, Messe Frankfurt will promote Techtextil with the subtitle “Performance. Function. Future.” and Texprocess with “Technology. Efficiency. Progress.”, thus giving greater emphasis to the dynamic and innovative nature of the sector. There will also be changes in the location of the two fairs. In 2021, they will move to the western section of Frankfurt Fair and Exhibition Centre for the first time and occupy Halls 8, 9, 11 and 12.

In addition to the exhibitor presentations at Techtextil and Texprocess, the two fairs will once again be supplemented by a variety of events, highlight themes and special features. Apart from the physical events planned, the two fairs will place greater emphasis on complementary digital features for exhibitors and visitors. They include, for example, live streams from conferences, new digital presentation options for exhibitors and opportunities for digital matchmaking between exhibitors and visitors.

For the first time in May 2021, Techtextil and Texprocess will share the Exhibition Centre with Heimtextil, atrade fair for home and contract textiles. The background to the postponement of Heimtextil is the current coronavirus situation coupled with the associated international travel restrictions. Although Heimtextil is normally held in Frankfurt am Main every January, next year represents a unique opportunity for it to join forces with Techtextil and Texprocess, and present additional synergistic effects along the textile value chain at the same time and place. By holding all three fairs concurrently, trade visitors will be able to obtain a comprehensive overview of functional materials for home and contract textiles, including the processing stages.

Source: messefrankfurt.com

Lenzing TENCEL-branded lyocell and modal fibers certified carbon zero

Following wider corporate commitments made by the Lenzing Group in 2019 to drive sustainability and combat climate change, the company has announced it has achieved carbon-zero for its TENCEL-branded lyocell and modal fibers. Following the guidelines of The CarbonNeutral Protocol, a global framework for carbon neutrality, carbon-zero TENCEL-branded fibers are certified CarbonNeutral products for the textile industry. This means that the emissions associated with the fibers’ production, manufacturing and distribution have been calculated and offset. Under the guidance of the TENCEL “true carbon zero” campaign, the TENCEL brand is contributing to Lenzing’s commitment to the Science Based Targets (SBT) initiative and its continuous support of the United Nations Sustainable Development Goals to limit global warming.

To date, the Lenzing Group is the first wood-based fiber manufacturer with approved Science Based Targets in the industry. Lenzing’s goal is to reduce its specific greenhouse gas emissions by 50% by 2030. Available from September, the newly launched carbon-zero TENCEL modal and lyocell fibers are contributing to this target through reduced production emissions and its industry engagement to lower energy consumption across the supply chain. In addition to offering new sustainable options to the textile and fashion industry, the new carbon neutral fibers show a clear commitment to Lenzing’s earlier announcement of investing more than EUR 100 million in reducing carbon emissions in its operational boundaries and supply chain.

Source: lenzing.com

DiloGroup to deliver needlefelt production line to FOSS Floors of Rome, Georgia

FOSS Floors, a specialist in needled carpeting, has ordered a new production line from DiloGroup. This will be become the 4th complete DILO line to further enlarge the production

capacity of FOSS Floors.

In recent years, FOSS Floors has become a major player in this sector of DI-LOOP carpeting to include structured surfaces in rib and patterned quality. Mainly because of high quality

requirements for the carpet product and a wide range of modern design patterns, needlefelt floor covering appeals greatly to architects and contractors for homes and commercial

buildings. The aim of gaining highly efficient additional capacity corresponds to a high demand for this particular carpeting from FOSS Floors.

DiloGroup has engineered this production system as a team together with FOSS, with the solution tailor-made for their needs. It will have a large production capacity at high fiber throughput rates, comprising fully automatic fiber opening and blending from Dilo Temafa, carding from Dilo Spinnbau in a wide working width, high-speed crosslapping, as well as pre and finish needling, designed for final product widths over 6 m. The specialty DI-LOOP machine with high-speed feature in a working width of 6.5 m will complete this production plant for the DI-LOOP carpet sector.

The total plant is to be delivered, assembled and commissioned by DiloGroup as general contractor.

Source: dilo.de

Robert W. Gore of W. L. Gore & Associates, inventor of GORE-TEX, dies at 83

Robert W. “Bob” Gore, chairman emeritus of the board of directors of W. L. Gore & Associates, a global material science company dedicated to improving lives through advancements in technology, passed away on September 17 at the age of 83.

Bob Gore, whose scientific discoveries spawned GORE-TEX Outerwear and paved the way for advancements in industries as varied as performance fabrics, medical devices, space exploration and filtration, assumed the chairman emeritus role in 2018 after 57 years of service on the Gore board, 30 of those as chairman. Bob also served as president of Gore from 1976 to 2000.

During his tenure as president, Gore became a billion-dollar enterprise. Marking the occasion in 1996, Bob said, “We plan to leave a legacy to society and to future generations: infants with surgically reconstructed hearts that live because of our medical products; governments of free societies that are better able to protect themselves because of defense products; communities with cleaner and healthier environments because of our filtration and sealant products; And yes, people that just have more fun in the outdoors because of our GORE-TEX Outerwear.”

Read W.L. Gore’s remembrance of Bob: https://www.gore.com/news-events/press-release/robert-gore-passing

Source: gore.com

Spinnova, Bestseller partner around sustainable fiber product development

Finnish fiber innovation company Spinnova and Danish multi-brand retailer Bestseller have partnered in a long-term sustainability journey. Being one of the early adopters of Spinnova’s sustainable fiber material is part of Bestseller’s sustainability strategy, Fashion FWD.

Spinnova and Bestseller will engage in joint product development to see which commercial products in Bestseller’s wide range of brands, such as VERO MODA, VILA and SELECTED, Spinnova’s sustainable fiber material would first suit.

Having proof of concept from its pilot production line, Spinnova is starting to build its commercial scaleup. Spinnova has a number of brand owners onboard, committed to long-term collaboration.

Bestseller’s Fashion FWD Lab focuses on new, low-impact and circular materials, better production, new business models and smarter ways of manufacturing.

Spinnova and Bestseller were introduced by the Fashion for Good initiative that works as a matchmaker for brands and innovators. Spinnova has been part of the Fashion for Good Scaleup programme from 2018-2020.

Source: spinnova.com

Ecofibre completes acquisition of TexInnovate, aims to expedite the commercialization of Hemp Black technology

Ecofibre (EOF) has completed the purchase of textile business, TexInnovate, to support the commercialization of its Hemp Black technology. Hemp Black is a hemp-made textile that can be used for a wide range of industries such as clothing and healthcare. By carbonizing a hemp bio-product, the technology unlocks a host of advanced technologies that are intelligent, adaptive and evolutionary, according to Ecofibre.

Last month, the company announced it will purchase TexInnovate for US$42 million (around A$58 million). Ecofibre says the success of Hemp Black relies on education.

The combined business is well-positioned to be a high-quality supply chain for customers who place a high value on corporate responsibility and environmental sustainability.

For more on this story: https://themarketherald.com.au/ecofibre-asxeof-completes-us42m-texinnovate-purchase-2020-08-24/

Source: ecofibre.com

Helsinki Fashion Week Designer Residency program features dress made of Spinnova sustainable fiber

KoH T, a designer in the Helsinki Fashion Week Designer Residency program, has revealed a unique gown dress he designed with Spinnova, a sustainable, wood-based fiber.

As part of the digital Designer Residency of the Helsinki Fashion Week, Spinnova was a mentor for Japanese fashion designer KoH T (Taisuke Kohji). Inspired by the human body, nature and the highly sustainable, natural Spinnova material, Taisuke used the Spinnova materials to create a gown dress that “feels like air.”

The multi-faced gown dress is well aligned with the Spinnova material that is 100% natural and made of wood without harmful chemicals. The design is both contemporary and nostalgic, resembling both Japanese and Nordic styles.

The dress is composed only of undyed fabric that is one of the first blends of Spinnova fiber with wool, and accessory ribbons that are a mixture of Spinnova and lyocell, also a wood-based fiber. Since the Spinnova fiber’s insulation capability is as good as wool’s, the dress is warm, yet breathable.

“The dress is about sustainability, style and high level of comfort. Instead of metal or plastic, only ribbons made of Spinnova are incorporated into the design. Hand-made pleats add ventilation functionality, and all patterns and structures are designed to fit human movement,” said KoH T.

“KoH T’s idea of creating something very close to nature was a great fit with our sustainable innovation. We firmly believe that wearing natural materials that don’t burden the environment create emotional wellbeing, which is something we all need more of, said Helsinki Fashion Week mentor, Spinnova’s application manager, Maree Hamilton.

The Designer Residency reached over half a million views during its seven-day streaming sessions prior to the virtual Fashion Week event.

Helsinki Fashion Week is an international medium for sustainable designers, brands and companies. It’s the first recognized fully sustainable fashion week in the world. Its 2020 edition was presented in an all-virtual format.

Source: spinnova.com

ProAmpac wins packaging design award

Flexible packaging leader ProAmpac was recognized in the 2020 American Inhouse Design Awards for its ProActive Recyclable retail shopping bag (pictured), which was designed in the companies Design and Sample Lab (DASL) in Cincinnati.The 57th American Inhouse Design Awards are presented by Graphic Design USA (GDUSA).

ProAmpac’s award winning design utilized the companies four-step creative process – ideate, illustrate, render and prototype – to facilitate new package development in an organized and rapid fashion. The process led to a series of recycling graphics and messages on paper bags designed to encourage area residents to increase at-home recycling.

The bag was introduced last year during Earth Day Over the Rhine, a Cincinnati event held in conjunction with the “Keep Cincinnati Beautiful” campaign in which ProAmpac donated over 1,000 units that were givenaway to attendees of the event.

Recently, ProAmpac launched DASL’s newest creative design tool, MAKR by DASL. MAKR allows users to remotely create custom three-dimensional package designs in both film and paper formats which can then be prototyped and shipped directly to the requestor.

Learn more about ProAmpac’s DASL: http://proampac.com/DASL

TSG Finishing announces immersion process now contains up to 30% plant-based technology

TSG Finishing announced the market launch of the first phase of incorporating plant-based technology into its DEFEND Finishing Program. Going forward, all high-performance DEFEND immersion processes now contain up to 30% USDA approved plant-based technology, making it one of the first performance brands in the market to claim this progress.

Through the efforts of TSG’s technical team, the plant-based DEFEND will also continue to offer high performance in repelling both water and oil-based products. The amount of PFAS (fluorinated chemical), also known as C6, is reduced by one-third in this new technology.

Brian Rosenstein, CEO states, “This is great progression regarding the reduction of the C6 footprint and seeking out the elusive ‘holy grail’ of textile finishing, which is a true fluorine- free treatment that will protect against both water and oil-based stains,” said Brian Rosenstein, TSG’s CEO. “Our team spent a lot of time vetting out different materials until we were satisfied that we had the right component. Having a USDA certified Bio-based product was key in our decision-making process.”

In the near future, TSG plans to cultivate this knowledge heading into more plant-based options, as well as expanding it into all of its DEFEND offerings.

Source: defendyourfabric.com

Monforts delivers high-capacity stenter to Acafintex facility in Puebla, Mexico

At a total length of over 71 metres, the Montex finishing line that has just been installed by Monforts for Acafintex at its plant in Puebla, Mexico, is one of the highest capacity stenters the German technology leader has delivered to date.

Founded in 1986, family-owned Acafintex operates as a commission dyehouse, finishing both knitted and woven fabrics for local companies in Mexico, in widths of between 100cm to 3.6 metres. The company is run by father and son team Don Francisco and Lic Francisco Moyano.

“We have very flexible operations for fabric finishing and also produce and sell our own fabrics for both the fashion industry and for the uniforms market,” says Don Francisco. “These days, we are increasingly finishing materials for technical textiles and for the automotive industry too. We have both local and international suppliers of both yarns and base fabrics and make sure we choose the best and most reliable sources. Exports now account for over 40% of our sales.”

With a width of 3.8 metres, the new Monforts Montex line at Acafintex is equipped with no less than 12 double TwinAir drying chambers to meet the requirements of specific technical textiles to a European customer, in a contract secured following the company’s ISO 9001 certification in 2019. The line is equipped with an integrated heat recovery system and also benefits from an exhaust air cleaning system to ensure the most resource-efficient processing available on the market.

On the Monforts TwinAir system, the airflows above and below the fabric being dried can be regulated completely independently of each other, with Optiscan Auto-Balance fully controlling the distance between the fabric and the dryer nozzles via variable-frequency fan motors and CCD chip evaluation. As a result, the evaporation rate of the stenter and its energy utilization are always fully optimized. Contact-free drying eliminates the possibility of fabric marking or stitch draft.

Highly-intuitive Monforts Qualitex visualization software allows all machine functions and process parameters to be assessed and controlled easily, and thousands of article specific settings and formulations to be called up at any time – with 100% reproducible results.

In combination with an existing Montex stenter, the new line has expanded finishing capacity at Acafintex to an annual 20 million linear metres.

Source: monforts.de

KC enters agreement to acquire Softex, bolsters position in Indonesian personal care market

Kimberly-Clark Corporation has entered into a definitive agreement to acquire Softex Indonesia, an Indonesian personal care company, in an all-cash transaction for approximately $1.2 billion from a group of shareholders including CVC Capital Partners Asia Pacific IV.

“This acquisition represents a compelling strategic fit and demonstrates our commitment to accelerate growth in developing and emerging markets,” said Mike Hsu, chairman and CEO, Kimberly-Clark. “Moreover, adding Softex Indonesia and its brands to Kimberly-Clark will enhance our company’s underlying growth prospects and help us create even more long-term shareholder value.”

Indonesia is a large, growing market with attractive future prospects, and the acquisition immediately improves Kimberly-Clark’s currently limited position in the country to one with strong market share in key personal care categories across Southeast Asia’s largest economy.

The diaper market in Indonesia is currently estimated at $1.6 billion, the sixth largest in the world, with approximately five million annual births. Approximately 80 percent of Softex Indonesia sales come from diapers, and it currently holds the number two market share position with the Sweety and Happy Nappy brands while continuing to grow its market presence.

Source: kimberly-clark.com

CINTE & CINC 2020 presented as first live technical textile and nonwovens event since COVID-19 outbreak

CINTE 20 & CINC 2020 were successfully presented by the China Nonwovens and Industrial Textiles Association September 2-4 in Shanghai. The 14th edition of the China International Trade Fair for Technical Textiles and Nonwovens (CINTE 20) was co-organized by CNITA, CCPITTEX and Messe Frankfurt.

The event was the first exhibition of technical textiles and nonwovens after the breakout of the COVID-19 pandemic, and it attracted nearly 500 exhibitors. The exhibits covered the entire industrial chain of technical textiles and nonwovens, including machines and accessories, raw materials and chemicals, nonwoven fabrics and products, other industrial textile rolls and products, functional fabrics, personal protective equipment, etc. The scale was 38,000 square meters, occupying the three major exhibition halls of Shanghai New International Expo Center. The number of visitors represented an increase compared to prior editions of the show, according the event organizers.

In an effort to promote the industry’s anti-pandemic deeds and display anti-pandemic products, the event included a display area of “Heroic Deeds of Anti-pandemic,” which featured innovative products of key anti-pandemic materials in the exhibition hall.

The 9th China International Nonwovens Conference (CINC 2020) focused on the theme of “Responsibility and Innovation of the Nonwovens Industry under the Pandemic,” presentations about investment, technological innovation, social responsibility and industrial chain collaboration in the nonwoven industry were delivered at site or via

video by many speakers from China, North America and Europe.

Li Lingshen, President of CNITA, reviewed the development of China’s nonwovens industry in 2019 and contributions of China’s nonwovens industry in the fight against COVID-19, described the outlook and social responsibility strategy of the nonwovens industry in the post-virus period. INDA President, Dave Rousse, and EDANA General Manager, Pierre Wiertz, made presentations via video. Rousse shared with attendees the functional foundation of nonwoven materials in three critical areas of facemask, medical and surgical gowns, and wipes for healthcare workers and all citizens, and reported on the latest capacity and production data in North America. EDANA highlighted the essential character of nonwovens industry after breakout of the pandemic. Mr. Wiertz gave an overview of what the European nonwovens industry and EDANA have done to contribute to the fight against COVID-19.

Source: cnita.org.cn

INDEX20 Innovation Awards virtual ceremony set for October 2020

The INDEX20 Innovation Awards, presented once every three years, was originally scheduled for April 2020. Due to COVID-19, EDANA has decided to present the awards in an online ceremony on October 6, 2020, from 3 p.m. to 4 p.m. The INDEX20 Innovation Awards are open to all INDEX20 exhibitors and EDANA members, for products commercially available by January 31, 2020, and have been selected by a jury of experienced industry members. The INDEX20 Innovation Awards are the highest accolade for the best examples of excellence in the industry, highlighting creativity and innovations from businesses of all sizes and roles within the business.

The awards are comprised of 7 categories covering all fields of the nonwovens supply chain, with a maximum of 3 nominees selected per category. The winners will not be disclosed until the online event on October 6, 2020.

Nominees are as follows:

- Nonwoven Roll Goods

- Fa-Ma Jersey – Microfly – nanocham AG+

- Jacob Holm – Sontara Dual

- Sandler – New ADL

- Finished products made from or incorporating nonwovens

- Callaly – Tampliner

- Dupont De Nemours – Dupont Tychem 2000 SFR

- Hassan Group – Heatable Geosynthetic Material

- Raw materials or components of special relevance to the nonwovens industry and related converted products

- Beaulieu Fibers International – UltraBond

- Omya International 0 Omyafiber 800 (Calcium Carbonate)

- Pelsan – Biodegradable breathable film for hygiene & medical market

- Innovation in machinery of special relevance to the nonwovens industry

- CAMPEN Machinery – new patented airlaid beater forming technology

- Dienes Werke für Maschinenteile – Depth Control Senso Plus (Led)

- GDM – Expandable Welding Wheel

- Achievement for the most original marketing campaign for a product made from or incorporating nonwovens

- Berry Global – J-Cloth Plus Biodegradable Communication Campaign

- Sustainable Product

- Ahlstrom-Munksjö – Fiber+, Green Capsule oxygen barrier lid, Compostable k-cup filter

- Beaulieu Flooring Solutions – Rewind-Forward thinking carpet

- RKW – RKW HyJet Crop Cover

- Sustainable process or management practice

- Diaper Recycling – Pureflow8

- Fatersmart – Closing the loop on used absorbent hygiene products

- TiHive – TULIPZ

Videos from the nominees will be posted on the indexnonwovens LinkedIn page, allowing observes and participants to vote in the “People’s Prize” by liking the nominee’s video that they feel is most deserving.

All the award winners’ and nominees’ submissions will be on display in the Nonwovens Innovation Lab, a new feature at the INDEX20 exhibition, taking place at Palexpo in Geneva, from September 7-10 2021.

Source: edana.org

Gelest ensures BIOSAFE antimicrobial product availability as demand continues to surge

Gelest, Inc has received U.S. EPA approval to use new manufacturing processes for its BIOSAFE antimicrobials, expanding its production capacities. Gelest has been working with suppliers to overcome material supply shortages and meet the increased demand for sanitizers, disinfectants and antimicrobials due to COVID-19. BIOSAFE Antimicrobials are found in a wide range of EPA-approved applications including Careismatic Certaintym SmartBoost Laundry Additive for healthcare uniforms, and National Wiper Alliance Quat Keeper Foodservice Towels for restaurants and cafeterias.

BIOSAFE antimicrobials are used to preserve treated articles by preventing the growth of stain and odor-causing bacteria, fungi, mold, and mildew.

Source: gelest.com

Eurofins Softlines & Leather publishes white paper on microplastics shedding from domestic laundry

Eurofins Softlines & Leather published a white paper titled “Microplastics from textile sources – Understanding the characteristics of microplastics shedding from simulated domestic laundry through quantification.”

Microplastics, referred to as particles of plastic smaller than 5mm, have become a controversial topic in recent years as more and more scientific researches expose the potential risks of microplastics to the human body, the ecosystem and the environment. Research by different institutes and organizations have indicated that the quantity of microplastics discovered in water bodies, as well as human bodies, is rising.

Shedding of microplastics from synthetic textiles during domestic laundry has been identified, in a study, as a key source of the primary microplastics found in oceans. However, given the lack of industry standards and regulation on textile-related microplastics release, it is challenging for the industry to measure its real impact and look for meaningful solutions.

Eurofins Softlines & Leather has developed an offering that assesses microplastics shedding quantification from textile products during simulated domestic laundry. Samples undergo simulated domestic washing (from single wash to multiple wash) in a controlled environment. Liquid is filtered to collect residue for analysis.

Based on close to 600 samples assessed from this offering, Eurofins Softlines & Leather publishes this White Paper sharing analysis with the industry in the hope of supporting the development of impactful solutions to this microscopic challenge. Highlights of the findings include:

- Fabrics and garments which are made with yarns containing fibers of longer lengths shed less particles into water.

- When comparing fabrics of the same composition and with similar weight, it cannot be concluded yet that the construction of the fabric directly results in a larger volume of microplastics being shed.

- The results show that the length of fibers shed in higher quantities are those that are between 0.45 µm and below 50 µm in measurement. These fibers are produced from one to ten washing cycles.

The white paper can be downloaded for free at https://www.eurofins.com/textile-leather/white-paper.

Source: https://www.eurofins.com/

Study shows most consumers consider wood-based textiles sustainable

According to an international study sponsored by Spinnova, 86% of consumers consider wood a sustainable textile raw material. Still, only one third are familiar with wood-based apparel. Consumers think brand sustainability image is the single most important sign of a conscious buying decision.

The study was made in Finland, Sweden, Germany, France and the U.S. in the spring of 2020. Wood was found the most sustainable out of currently available textile raw materials. The highest sustainability rating over wood was given to emerging, waste-based raw materials. Nordic respondents were most pro wood; 90% of Finns and 91% of Swedes consider wood a sustainable textile raw material.

According to the study, harmful chemicals are seen as the worst environmental problem of the textile industry; 64% considering this an issue. 60% also associated excessive water use a problem of the industry, followed by ocean microplastics, waste and CO2 emissions.

When asked what factors make up a sustainable image of a product, brand sustainability image got the most replies, 54%. Only 29% of respondents thought high price is a sign of sustainability. Environmental certificates were considered an indicator of sustainability by 48%.

Despite the positive take on wood, only a third of all respondents had experience of wood-based textiles, although man-made cellulosic fibers have been around for decades. However, 55% did consider the idea of wood-based apparel appealing. When asked the same question regarding apparel made of plant-based waste, as much as 76% said they would find it an appealing choice.

Source: https://spinnova.com/

SAERTEX announces new production site in Mexico

Like its facilities in Huntersville, North Carolina (USA) and Indaiatube (Brazil), the Ciudad Juárez plant will focus on meeting demand for SAERTEX composite materials in the region and the Americas, as well as conserving resources by shortening delivery routes.Ciudad Juárez is one of the fastest growing cities in Mexico, and international companies such as Bosch, Siemens, Honeywell, and Foxconn are settling there. In addition, the area has become an important hub for the production of rotor blades for the wind industry.

Freudenberg starts new production line in Taiwan with focus on technology and sustainability

Freudenberg Performance Materials completed the installation of a spunlaid line in Taiwan and will begin production of nonwovens for diverse markets. The new production line features the latest spunlaid technology developed by Freudenberg. The technology enhances filament distribution for increased material uniformity, providing customers with ease of processing the nonwovens for a variety of applications. The line also utilizes AI technology to detect variances in the material and automatically adjust uniformity as well as an IR camera to identify small melt defects.

In addition to the new technology, the production line features enhancements to reduce environmental impacts. All parts used in construction were selected to lessen CO2 emissions during operation. The Taiwan site also invested in a recycling system to recycle all start-up materials and scrap materials during normal operations, helping to reach zero-waste operations. The spunlaid line will run partially on solar energy supplied from panels installed on-site last year.

Source: freudenberg-pm.com

59th Global Fiber Congress presented as “Webinar Week”

Due to the coronavirus pandemic, the 59th Global Fiber Congress will now be presented online as a “Webinar Week” between September 16 and 18, 2020. Three technology experts from the Manmade Fibers Segment of the Swiss Oerlikon Group will take part in the presentations and discussions. The focus of the ‘Dornbirn-GFC 2020 – Webinar Week’ will be on speeches and discussions on the following topics: ‘Smart, Integrated, Digital Textile Production Chain’, ‘Personal Protective Equipment (PPE) – a Challenge for the Industry in Europe?’, ‘New Recycling Technologies – what are the Challenges?’, ‘Circular Economy in the European Industry Recovery’ and ‘Future Rules & Regulations for Textiles – what should be expected from the EU?’.

The opening speech comes in the form of a keynote on the topic of “The Green Deal and its Implications for the Textile Industry” by Leonore Gewessler. She is the Federal Minister for Climate Protection, Environment, Energy, Mobility, Innovation, and Technology for the Republic of Austria, a position she took over in January 2020.

Sylvain Huck, Technology Manager Digtal at Oerlikon Manmade Fibers, will be talking on the topic of “Yarn DNA supported by Digitalization” on September 16, 2020, between 1 and 1:20 p.m. The following day, Head of Product Management at Oerlikon Manmade Fibers Markus Reichwein will be addressing “On the Road to a Sustainable Manmade Fiber Industry” beginning at 2 p.m. on September 17. In his ‘Leading Meltblown Technology for the Production of Face Mask Filter Media’ presentation, Dr. Ingo Mählmann, Head of Sales & Marketing at Oerlikon Nonwoven, will cover the secrets of meltblown technology at 9:40 a.m. on September 17.

Information and registration for the webinar: dornbirn-gfc.com

All-virtual World of Wipes International Conference attracts 260+ attendees

INDA, the Association of the Nonwoven Fabrics Industry, hosted its 14th annual World of Wipes (WOW) International Conference in an all-virtual format, Aug. 25-27. The event was attended by more than 260 participants from 20 countries, with features including conference presentations, live Q&A, tabletop display rooms, live chat, cocktail hours, afternoon tea, and coffee connections.

The event featured presentations from 30 industry leaders on issues, market trends, and statistical data to plan business strategies as well as a virtual three-day Wipes Academy training course.

Food Fresh Liners from Berk International LLC was the winner of the 2020 World of Wipes Innovation Award. Food Fresh Liners are the first nonwoven that can absorb accumulated moisture in sealed produce packaging to keep produce from wilting and spoiling, thus staying fresher for longer. The annual award recognizes the product that best expands the use of nonwovens and demonstrates creativity, novelty, uniqueness, and technical sophistication within the entire nonwovens wipes value chain.

“We are reinventing our approach to conferences to meet the connection and content needs of our industry participants, as well as the social distancing and hygiene needs of the current COVID-19 situation we are in. At the World of Wipes®, we were encouraged by our attendees’ ability to adapt to the new technology platform and variety of modes we put forward to creatively interact,” said Dave Rousse, INDA President.

Source: inda.org

Event Site: worldofwipes.org

* International Fiber Journal is owned by INDA, Association of the Nonwoven Fabrics Industry (inda.org).

Americhem acquires Controlled Polymers

Americhem, a globally recognized designer and manufacturer of custom color masterbatch, functional additives, engineered compounds, and performance technologies, has announced that it has acquired Controlled Polymers, a leading global manufacturer of customized compounds and masterbatch for the medical industry and other industries. With 30 years of experience, Controlled Polymers is located in Denmark and supplies sustainable polymeric solutions to some of the largest healthcare OEMs in the world.

Controlled Polymers will integrate with Americhem and its Engineered Compounds division (AEC) by blending the companies’ product lines together to create a full range of offerings for customers in the medical plastics and other industries. Controlled Polymers has developed a specialized portfolio of products integral to many medical device and healthcare applications, including a particular strength in the hearing aid industry.

This acquisition expands Americhem’s global reach with increased product offerings, extended service capabilities, and broadened technical expertise. In particular, Controlled Polymers has built deep subject expertise in medical compounds and masterbatch through strategic customer partnerships. Other industries served include packaging, consumer goods, electronics, construction, and automotive where Controlled Polymers distinguishes itself through flexible lot sizes, industry leading lead times, and exceptional color matching capabilities.

Americhem’s CEO, Matthew Hellstern, stated, “We are thankful that our successes at Americhem have allowed us to continue expanding our portfolio by bringing other like-minded companies into our Americhem family.”

CEO of Controlled Polymers, Mogens Larsen, stated, “We are delighted to join the Americhem family and specifically Americhem Engineered Compounds. Our companies’ customers will continue to experience the same dedicated quality and service as always, but with an expanded global reach and deeper breadth of product offerings.”

Source: americhem.com

Lindner and Erma machinery provide foundation for new recycling plant in Slovenia

Ljubljana, Slovenia inaugurated a new recycling plant for processing industrial plastic waste, in particular plastic film. The new facility features a universal and state-of-the-art washing system from Lindner Washtech with a range of new and improved components, such as a Micromat 2000 shredder, a highly effective pre-wash unit Floater extend and a mechanical dryer of the Loop Dryer series. The washed flakes are regranulated by an Erema Intarema 1714 TVEplus extruder. The plant has been up and running around the clock five days a week for several weeks now.

With 19 waste depots in operation, Dinos is considered one of the largest waste management and recycling companies in Slovenia. The company collects and recycles non-ferrous materials (glass, wood, plastic and paper), metals (all types of old and new industrial scrap, steel, stainless steel and cast iron) and non-ferrous metals (aluminium, copper, nickel and tin). After collecting the waste material, it is sorted and then processed. Dinos has been part of the German Scholz Group since 2012.

“In the past 15 years, in the plastics sector Dinos focussed mainly on collection and pressing or shredding”, explains Plant Manager Jure Jambrovic, “But due to the changing situation on the world market where the placement of plastic waste has become increasingly difficult, we’ve decided to start our own recycling line. This will enable us to offer the market a high quality end product.”

The primary materials processed are LDPE and LLDPE clear wrap (mainly packaging films from the industrial sector & supermarkets), mixed post-consumer LDPE films, HDPE drums and HDPE canisters (primarily post-commerical packaging) and PP (crates and packaging).

Source: lindner.com