In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant to our industry from manmade to natural to bio-based fibers, innovations in nonwoven, woven, braided and technical textiles, technologies for additives, bonding, coatings and polymers, and applications from apparel to hygiene to transportation, and more. Here we will post news stories relevant to textile fibers and their downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg at ken@ifj.com.

Most recent update: March 30, 2022

PolyQuest launches PQRenew recycled Bottle Flake and Resins

PolyQuest, Inc. officially announced the company has trademarked its PQRenewTM brand of recycled bottle flake and resins – an exclusive product line furthering sustainability solutions.

Since 2006, the Wilmington, North Carolina based company has been systematically developing its owned and tolled asset infrastructure and has produced over 1 billion lbs. of high-quality post-consumer bottle flake (rPET flake), post-consumer resin (rPET PCR), and post-industrial resin (PIR), which are now branded as PQRenew.

The PQRenew brand is a natural extension of PolyQuest’s amplified recycling footprint across the U.S., including operational enhancements at PQ Recycling in Farmingdale NY, and PolyQuest’s recycling facility in Darlington, SC. PolyQuest remains dedicated as an invaluable resource, partner, and key distributor of virgin thermoplastics and manufacturer of recycled thermoplastics.

“The comprehensiveness of the PQRenew product portfolio allows customers to choose various technical options for recycled PET,” indicated John Marinelli, PolyQuest’s CEO. “The key for us moving forward is to select partners that have strategically and financially committed to sustainability, who mesh well with our culture and values, and have common goals and objectives. Win-win would be our condensed perspective on these relationships.”

PQRenew includes 100% recycled content applications and top mechanical recycling technologies reducing waste and greenhouse gas emissions. More details are located on polyquest.com/pqrenew including key PQRenew product highlights.

Source: PolyQuest

VEOCEL™ brand partners with Suominen to champion carbon neutral nonwovens fabrics

Lenzing’s VEOCEL™ brand announced that Suominen, the globally leading nonwovens supplier and manufacturer for wipes, is the first partner to adopt the industry’s first carbon neutral VEOCEL™ branded lyocell fibers.

Carbon neutral VEOCEL™ Lyocell fibers were first introduced by Lenzing in June 2021 as a solution for nonwovens industry partners and brands to reduce climate impact through the use of fibers with a net-zero carbon footprint. Materials and goods produced with VEOCEL™ Lyocell fibers signify Lenzing’s care for the environment and commitment to offering climate friendly solutions which limit global warming.

“Recently, an industrywide shift towards carbon neutrality has been observed in Europe, with many companies transforming to an eco-friendly business model. With VEOCEL™ and Suominen coming together to offer carbon neutral fibers for nonwovens in Europe, we hope to address the growing demand from brands and consumers for products with a reduced carbon footprint,” said Jürgen Eizinger, Senior Commercial Director EU/AM/MEA at Lenzing. “The VEOCEL™ brand will remain committed to reducing the impact of climate change by offering innovative solutions for our nonwovens partners, paving the way for a net-zero nonwovens industry.”

Source: Lenzing

Renewcell and fiber producer Daiwabo sign Letter of Intent for circular textile fiber collaboration

The Swedish textile-to-textile recycling innovator Renewcell has signed a Letter of Intent with Daiwabo Rayon Co. Ltd., a leading Japanese cellulosic fiber producer, concerning a long-term commercial collaboration around manmade cellulosic fiber production. The agreement affirms the two companies’ intent to work together to supply textile fibers made using Circulose®, Renewcell’s 100% recycled textile raw material, to global fashion brands in the coming years. The agreement has been facilitated by Ekman Group, Renewcell’s exclusive global trading partner.

“The Letter of Intent signed between Renewcell and Daiwabo provides the framework for an upcoming offtake agreement between the parties. The future legally binding offtake agreement will set out commercial terms for the delivery of certain volumes of Circulose® dissolving pulp to Daiwabo over a number of years. Daiwabo intends to use Circulose® as feedstock in the production of man-made cellulosic fibers to be supplied to textile manufacturers and fashion brands worldwide.

Pratrivero USA to open new operations in South Carolina

Pratrivero USA, a division of Pratrivero Nonwovens – a global leading producer of nonwoven fabric using stitchbond technology –announced plans to establish new operations in Orangeburg County in South Carolina. The company’s $17.6 million investment will create 34 new jobs.

Headquartered in Italy and family-owned and operated for 14 generations, Pratrivero Nonwovens provides fabrics used in a variety of sectors including furnishings, advertising banners, footwear, packaging and the automotive industry.

Located at 3777 Industrial Blvd. in Orangeburg, Pratrivero USA’s Orangeburg County facility will produce stitchbond, a nonwoven fabric produced by mechanical bonding of fiber layers with continuous filaments. The facility will also include distribution operations.

Operations are expected to be online in September 2022. Pratrivero USA is working with readySC to support future recruitment.

Source: SC Governor

BB Engineering GmbH records order intake from Thai Polyester for four VacuFil recycling systems

BB Engineering GmbH (Germany), a subsidiary of Oerlikon Textile, announced that Thai Polyester Co., Ltd. (Thailand) has placed an order for four VacuFil systems for recycling bottle flakes with connected direct spinning.

The polyester manufacturer, established in 2001 and with an overall annual capacity of 316,800 tons, is one of Thailand’s leading producers and exclusively uses German technology. To this end, the company already operates Oerlikon Barmag and Oerlikon Neumag systems. The BB Engineering VacuFil systems will be deployed to convert existing spinning plant equipment from processing polyester to processing PET bottle flakes without loss of performance.

BB Engineering supplies the complete recycling process – from the drying stage and extrusion, all the way through to the spinning plant-appropriate fine filtration stage. Thanks to decades of experience in spinning plant technology, the German machine constructor also provides comprehensive spinning plant know-how and is aware of how the recycling process must be designed to ensure that the product manufactured using the spinning plant ultimately has the right quality.

The four new VacuFil systems will be integrated into the existing building infrastructure and process landscape at Thai Polyester, with a total output of approx. 4,000 kg/h. The Vacu-Fil systems will be complemented by BB Engineering 3DD mixers for directly feeding dyes into the recycled melt flow. Commissioning has been scheduled for 2023.

Thai Polyester will be using the new VacuFil systems to manufacture its ‘EcoTPC’ recycling-brand yarns. 100% of these polyester yarns are produced from bottle, fiber and yarn waste and are all GRS certified.

Source: BBEngineering

PFNonwovens is accredited with ISCC+ re-certification at its facility in Znojmo, Czech Republic

PFNonwovens, a global leader in the production of customized, innovative nonwovens, announced that its Znojmo, Czech Republic facility has again passed the International Sustainability and Carbon Certification Plus (ISCC+) audit this month. The ISCC Plus certification enables traceable supply chains for mass-balance solutions of sustainable raw materials (recycled and bio-based).

“The ISCC Plus certification demonstrates PFNonwovens’s commitment to provide sustainable solutions to its hygiene and medical customers. We offer a range of products based on the mass-balanced approach, as well as nonwoven fabrics with a high content of bio-sourced polymers and recycled polymers” said Tonny de Beer, Chief Product, Technology and Sustainability Officer. “In addition, all of our nonwovens in Znojmo are produced with renewable energy”.

Source: www.pfnonwovens.com

AATCC Foundation Raises $144,000 for Scholarships

The AATCC Foundation 100 for 100 campaign raised more than $144,000 and established endowments to permanently provide for two of the underfunded graduate fellowships.

Donors capped off AATCC Foundation’s fundraising campaign with a hands-on tapestry project at the AATCC Week of Celebration in November 2021. Each person or company donating $100 or more during the week also added to a woven tapestry that is now displayed at the AATCC Technical Center.

The two fellowships now fully endowed are the Connelly/Perkins Fellowship awarded to Ph.D. candidates at the Clemson University Department of Materials Science and Engineering (MSE) and the Grady, Hauser, Houser, Daniels Fellowship for Ph.D. candidates in Fiber and Polymer Science at the North Carolina State University Wilson College of Textiles.

Source: aatcc.org

The LYCRA company announces settlement in patent infringement cases

The LYCRA Company, a global leader in developing innovative fiber and technology solutions for the textile and apparel industry, announced a settlement related to its ongoing global efforts to protect its intellectual property (IP), including patents and trademarks, from infringement worldwide.

The Jiangsu Authority in China recently mediated a lawsuit initiated by The LYCRA Company against four companies found to be infringing on its dual core patents for denim.

“The cases for infringement have been decided,” said Bridget Sciamanna, general counsel, The LYCRA Company. “In consideration of dropping charges against all the companies involved, a financial settlement has been reached for an undisclosed amount. In addition, these companies have agreed to cease infringing on our patents.”

Source: LYCRA

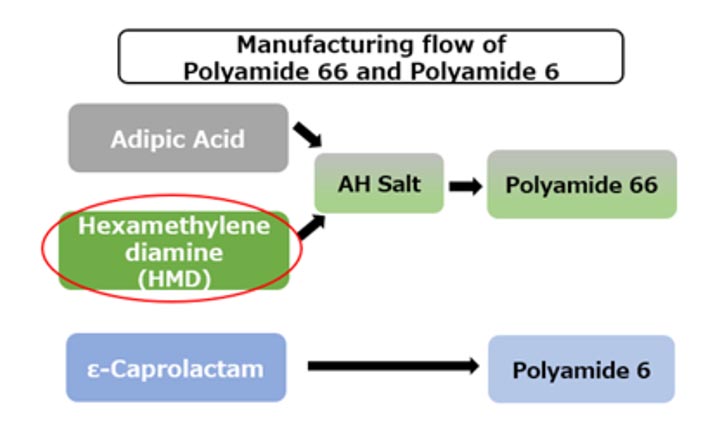

Asahi Kasei to accelerate trials for commercialization of polyamide 66 made using biomass-derived intermediate

Asahi Kasei has formed a strategic partnership with US-based Genomatica regarding hexamethylenediamine (HMD) based on biomass-derived raw materials (bio-HMD).

Asahi Kasei currently uses fossil fuel–derived HMD as an intermediate to manufacture Leona™ polyamide 661,2, an engineering plastic featuring outstanding heat resistance and rigidity. Polyamide 66 is used for plastic parts in automotive and electronics applications, as well as yarn for airbag fabric. Demand for polyamide 66 is expected to increase worldwide.

As the world moves toward carbon neutrality, attention is increasingly focused on solutions for reducing greenhouse gas emissions from chemical products derived from fossil fuels. The strategic alliance with Genomatica provides Asahi Kasei with preferential rights to access the early volume of bio-HMD to evaluate the possibility as a feedstock of polyamide 66, enabling Asahi Kasei to accelerate trials of polyamide 66 made using biomass-derived intermediate. Genomatica has an established track record of commercializing manufacturing technology for various chemical products using biotechnology. By using this bio-HMD with its own polyamide 66 polymerization technology, Asahi Kasei aims to support its goal to be first-to-market with more sustainable polyamide 66 made using biomass-derived intermediate for the automotive and electronics application of plastics components and industrial fiber.

Asahi Kasei moreover expects that this use of biotechnology will contribute to reaching its goal of becoming carbon neutral by 2050, while also alleviating the environmental burden throughout the life cycle of customers’ products. Asahi Kasei will continue to strive for adoption of biomass-derived intermediates for its engineering plastics in addition to polyamide 66, while proactively utilizing recycled material, aiming to be a global sustainable partner for its customers.

Source: Asahi Kansei

Milliken & Company Named to 2022 World’s Most Ethical Companies for 16th Straight Year

Milliken & Company has been recognized by Ethisphere, a global leader in defining and advancing the standards of ethical business practices, as one of the 2022 World’s Most Ethical Companies. The diversified global manufacturer, with more than 60 locations and approximately 8,000 associates worldwide, is one of six companies to receive this prestigious ethics-based honor every year since the award’s inception.

“Ethisphere and its World’s Most Ethical Companies program is a key benchmark for the way we do business,” said Halsey Cook, president and CEO for Milliken & Company. “Receiving this recognition for 16 straight years underscores the culture and commitment of Milliken team members globally. It’s who we are.”

In 2022, 136 honorees were recognized, spanning 22 countries and 45 industries. Milliken is one of seven industrial manufacturers.

“Congratulations to Milliken for achieving recognition as one of the World’s Most Ethical Companies for the 16th time,” said Ethisphere CEO Timothy Erblich. “We commend the entire Milliken team for this truly significant achievement and their commitment to driving positive, lasting change by intentionally creating a culture of ethics and purpose.”

Milliken & Company is a global manufacturing leader whose focus on materials science delivers tomorrow’s breakthroughs today. The company draws on thousands of patents and a portfolio with applications across the textile, flooring, chemical and healthcare businesses.

Source: Ethisphere

US jeans imports up 22.5% in January

Import of denim to the US rose in January by 22.5 percent from a year earlier, totaling $305.19 million. A new report from Research and Markets forecast the global denim jeans market to grow to $76 billion by 2026, up from $57 billion in 2020.

successfully targeted as a special application for Lenzing fibers. Photo courtesy of Lenzing

All five of the top supplier countries with more than 10 percent of the import market posted increases, with Bangladesh leading the pack with an increase of 9.99 percent year over year to $62.03 million in January. The No. 2 supplier, Mexico, saw its shipment increase by 28.68 percent to 53.89 million. Vietnam surged 49.19 percent to $37.25 million, Pakistan 32.76 percent to 34.52 million and China by 17.13 percent to 33.31 million.

Source: Rivet

Michael Berg nominated as Chairman of the Board of Directors of Renewcell

The nomination committee of the Board of Directors of Re:NewCell AB (‘Renewcell’) has nominated Michael Berg as a Member and Chairman of the Board of Directors. His appointment to the board is subject to a decision at the Annual General Meeting on May 17, 2022.

Renewcell’s current Chairman, Mia Hemmingson, has declined reappointment to the position but is nominated to remain a member of the Board of Directors alongside the other current members; Helene Willberg, Henrik Ager, Anna Attemark and Om Bhatia.

Michael Berg has many years of international experience in both operational and board positions within listed and unlisted companies. As Chairman at Renewcell, Michael Berg will contribute knowledge gathered across many industries and the various companies that have grown quickly and successfully under his leadership. He has previously held several international executive positions within Tetra Pak, been CEO of Envirotainer and Polygon AB and Chairman of the Board of companies such as the construction waste recycling company Sortera AB. He is currently Chairman of Lowenco A/S, Babybjörn AB and Proxify AB.

Source: renewcell.com

PCMC augment leadership team

Paper Converting Machine Company (PCMC), as part of Barry-Wehmiller’s Converting Solutions platform, has filled several key roles on the leadership team in Green Bay in alignment with the platform’s strategic plan to grow local operations and expand its global footprint.

“Bringing together our global team to operate as one will drive innovation and help us better serve our customers who operate worldwide,” said Stan Blakney, Group President of BW Converting Solutions and PCMC. “Our augmented leadership team will allow us to better manage our expanding global footprint, enable us to offer our team members more professional opportunities and ensure we maintain our people-focused culture as we grow.”

Scott Bean has joined as Executive Vice President of Operations. He will drive manufacturing capacity and excellence across the platform’s five facilities in Green Bay, as well as its European locations in Lucca, Italy; Neuwied, Germany; and Čačak, Serbia. Bean brings 20-plus years of experience leading operations at several large global manufacturers, including Milwaukee-based Rexnord and most recently, Filtration Group, where he served as a President.

Jason Hilsberg, who joined PCMC in 2003 as a Field Service Leader and has held numerous other roles, including Sales Director, has been named Vice President of Lifecycle Support. In his new role, he leads the global field service, customer technical support and equipment modification sales teams.

Kelly Morgano has joined as the Global Vice President of People. In her new role, Morgano will lead the human resources, culture, communications and people development functions, while supporting the platform’s commitment to caring for team members. She has worked in human resources for more than 20 years, most recently with Zurn Water Solutions.

PCMC and its divisions, Hudson-Sharp and Northern Engraving, have expanded their footprint in the tissue and nonwovens-converting, bag-converting and flexographic-printing equipment markets in recent years, reporting significant revenue growth in 2021. The company has been a fixture in Green Bay since 1919.

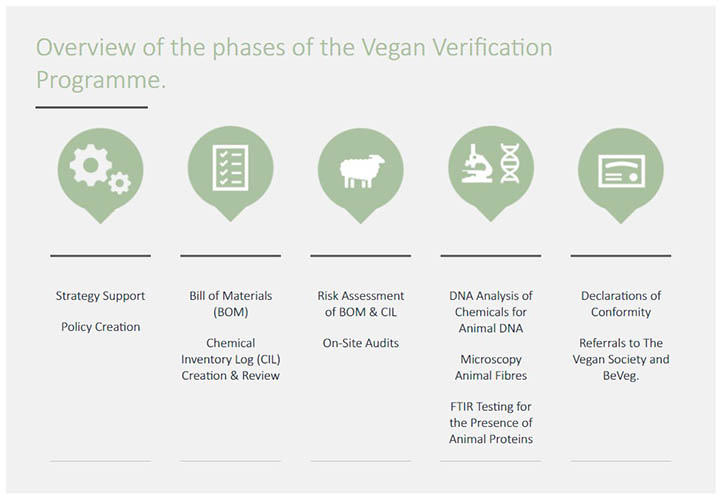

Coveme S.p.A awarded Eurofins | Chem-MAP Vegan Verification for Kemafoil® KTR®

Eurofins | Chem-MAP are pleased to confirm that Coveme S.p.A Ltd. has been awarded the Vegan Verification Mark for their Kemafoil® KTR® heat transfer films.

The Vegan Verification program developed by Eurofins | Chem-MAP, gives manufacturers and retailers the assurance that raw materials used in the production of materials and, ultimately the finished product, have not been derived from animal origin.

Used extensively in the textile industry, Coveme S.p.A ‘s heat transfer films have been rigorously tested for animal derived ingredients using a combination of PCR analysis for the presence of animal DNA and FTIR analysis.

Coveme is specialized in the design and manufacturing of value-added films, especially polyester. Its brand Kemafoil® KTR® covers a range of release films for the print and casting with final application in Fashion and Sports apparel, product Merchandising, Workwear, Automotive and Printed Electronics.

‘The Vegan Verification program offers manufacturers a robust testing program that can help with supporting Vegan product claims. Awarding Coveme with the Vegan Verification Mark and Certification for their heat transfer films, will give their customers the reassurance that they are purchasing a verified vegan product, said Georgina Mawer, head of Eurofins | Chem-MAP – Vegan Verification program.

Source: Chem-MAP

Globally Cellulose Acetate Fiber Market Size & Share to Surpass $7.0 Billion by 2028

The Global Cellulose Acetate Fiber Market size is expected to reach over USD 7.0 Billion by 2028. The Market stood at a revenue of USD 4.9 Billion and is expected to exhibit a Compound Annual Growth Rate (CAGR) of 4.6% during the forecast period, according to a new report by Vantage Market Research.

Cellulose Acetate Fiber are used widely in furnishings and home bedding as well as in women apparels. Furnishings & home bedding such as upholstery, carpets, linen, bedspreads, curtains, and others are produced with the use of these fibers. Additionally, these fibers gives luxurious appearance and feel to the home fashion items and can also be obtained in a range of sheens and colors. Excellent softness and drapability are also major features of these fibers owing to which these are being used in draperies, stated Vantage Market Research, in a report, titled “Cellulose acetate fiber Market by Type (Fiber, Plastics), by Application (Cigarette Filters, Textiles & Apparel, Photographic Films, Tapes & Labels), by Region (North America, Europe, Asia Pacific, Latin America) – Global Industry Assessment (2016 – 2021) & Forecast (2022 – 2028)”.

Source: Vantage Market Research

Lenzing completes expansion of lyocell plant in Thailand; touting it as world’s largest

The Lenzing Group, a leading supplier of wood-based specialty fibers, is pleased to announce the successful completion of its key lyocell expansion project in Thailand. The new plant, the largest of its kind in the world with a nameplate capacity of 100,000 tons per year, started production on schedule and will help to meet the increasing customer demand for the company’s TENCEL-branded lyocell fibers.

Construction of the plant, located at Industrial Park 304 in Prachinburi, around 150 kilometers northeast of Bangkok, started in the second half of 2019 and proceeded largely according to plan, despite the challenges arising from the COVID-19 pandemic. Investments (CAPEX) amounted to approx. EUR 400 million.

In 2019, Lenzing made a strategic commitment to reducing its greenhouse gas emissions per ton of product by 50% by 2030. The vision is to be climate-neutral by 2050. Due to the established infrastructure, the site in Thailand can be supplied with sustainable biogenic energy, contributing to the company’s climate neutrality goals.

Together with the key project in Brazil and the substantial investments at the existing sites in Asia, Lenzing is currently implementing the largest investment program in its corporate history (with more than approx. EUR 1.5 billion). Lenzing will continue to drive the execution of its strategic projects, which are expected to make a significant contribution to earnings from 2022, according to the company.

“We are very proud of this achievement. Our sincere thanks go to the entire Lenzing team and especially to our staff in Thailand, but also to many external stakeholders, who joined forces in times of a global pandemic to make this key project reality. To deliver such a huge project in time and at budget is an outstanding achievement given the challenges of the global pandemic”, said Cord Prinzhorn, CEO of Lenzing Group.

Robert van de Kerkhof, member of the Managing Board, added, “The demand for our wood-based, biodegradable specialty fibers under the TENCEL, LENZING ECOVERO and VEOCEL brands is growing very well. In Asia in particular, we see huge growth potential for our brands based on sustainable innovation. With the production start of the lyocell plant in Thailand, Lenzing reached an important milestone in its growth journey, supporting our ambitious goal to make the textile and nonwoven industries more sustainable.”

Lenzing will continue to expand its production capacity for lyocell fibers in line with its sCore TEN strategy, which aims to generate 75% of its fiber revenue from eco-responsible specialty fibers such as TENCEL, LENZING ECOVERO and VEOCEL fibers by 2024. The Thailand site offers space for several production lines. The investment in the first phase already includes general infrastructure that would benefit future expansion. However, the company said it will continue to look for opportunities to expand lyocell production in other parts of the world too.

Source: lenzing.com

Messe Frankfurt suspends events in Russia

Mess Frankfurt has decided to suspend its events in Russia due to unrest in the area related to Russia’s invasion of Ukraine. According to a statement released by Messe Frankfurt:

“The Russian invasion of Ukraine poses an unprecedented threat to peaceful coexistence in Europe. Messe Frankfurt supports all sanction measures taken by the federal government. Against this backdrop, the Messe Frankfurt Board of Management decided to suspend events of its subsidiary Messe Frankfurt RUS until further notice.”

In the textile space, this decision may impact Techtextil Russia, scheduled for Sept. 20-22, 2022, in Moscow, and Texcare Forum Russia, scheduled for Fall 2022 in Moscow.

Source: messefrankfurt.com

BASF to build new plant for alkylethanolamines at Antwerp site

BASF announced plans to build a new global-scale production plant for alkylethanolamines at the Verbund site in Antwerp, Belgium. After the planned start-up in 2024, the company will increase the global annual production capacity of its alkylethanolamines portfolio containing, amongst others, dimethylethanolamines (DMEOA) and methyldiethanolamines (MDEOA) by nearly 30% to more than 140,000 metric tons per year. With a high degree of local backward integration, BASF ensures a reliable and sustainable production of alkylethanolamines. With production facilities for this portfolio at its sites in Ludwigshafen, Germany; Antwerp, Belgium; Geismar, Louisiana and Nanjing, China, BASF is one of the world’s leading producers of alkylethanolamines.

“We see a continuing, growing demand for alkylethanolamines in a broad range of industries such as water treatment, detergents and gas treatment over the next years. The investment in Antwerp will have a positive effect on the available capacity for alkylalkanolamines in BASF’s amines Verbund, therefore supporting our continued ambition to provide products for our customers’ growth,” said Dr. Frank Stein, regional business unit Europe of BASF’s Intermediates division, adding: “This is our clear commitment as one of the globally leading amines producers.”

The versatile alkylethanolamines are mainly used as precursors for flocculants applied in water treatment and in the coatings industry where they act as binders between pigments and resins. Other applications include gas treatment, fabric softeners, in additives for metalworking fluids and polyurethanes.

With about 300 different amines, BASF has a diverse portfolio of this type of chemical intermediates. Along with alkyl-, alkanol- and alkoxyalkylamines, the company offers heterocyclic and aromatic as well as specialty amines. The range is completed by an expanding portfolio of chiral amines of high optical and chemical purity. The products are used to manufacture process chemicals, pharmaceuticals and crop protection products, as well as cosmetic products and detergents. They also serve to produce coatings, special plastics, composites and special fibers.

Source: basf.com