In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant to our industry from manmade to natural to bio-based fibers, innovations in nonwoven, woven, braided and technical textiles, technologies for additives, bonding, coatings and polymers, and applications from apparel to hygiene to transportation, and more. Here we will post news stories relevant to textile fibers and their downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg at ken@ifj.com.

Most recent update: July 29, 2024

Raoul Farer Joins NC State Wilson College of Textiles and Nonwovens Institute

Raoul Farer PhD has been appointed professor at North Carolina State University’s Wilson College of Textiles and executive deputy director at The Nonwovens Institute (NWI).

Dr. Farer will serve as professor in the Wilson College of Textiles’ Department of Textile Engineering, Chemistry and Science (TECS). As executive deputy director with NWI, Dr. Farer will join the Institute’s leadership team, working closely with Behnam Pourdeyhimi PhD, and Tom Daugherty to manage the implementation of NWI’s strategic vision.

Dr. Farer joins TECS and NWI after a 24-year career with Freudenberg Performance Materials in Germany, Spain and the United States, bringing extensive knowledge in textile technologies with a specialization in nonwovens.

Throughout his career, Dr. Farer has championed investments in new equipment and upgrades in technology to improve the uniformity of nonwovens, optimize and modernize technologies to help reduce energy consumption, while also allowing for increased usage of recycled materials. During the Covid-19 pandemic, Dr. Farer and Freudenberg partnered with NWI and NC State to build a full-scale FDA-approved face mask production facility in Durham, North Carolina.

Trützschler Reports Strong Sesults for Next-Generation Carding Machine

Trützschler’s next-generation carding machine TC 30i entered the market in January 2024 – and the company reports strong results from customers using the machine. The machines have achieved excellent results during tests with customers in Türkiye and other countries, achieving up to 40 % higher productivity while reducing energy consumption by up to -18 %.

Mayfil Tekstil, a leading company in the Turkish textile industry for the production of textured yarn invested in a modern vortex airjet spinning facility in 2022 that can produce up to 35 tons per day. And the company was keen to take a close look at the TC 30Si for man-made fibers to explore its potential to drive progress toward Mayfil’s ambitious growth plans. In February 2024, Mayfil Tekstil conducted tests with the TC 30Si. The next-generation carding machine produced 140 kg/h viscose, which is more than 40 % higher than the 95 kg/h Mayfil produces with the current benchmark. The new carding machine also decreased electricity consumption by 18 %. Based on these results, Mayfil is purchasing further TC 30i cards, according to Trützschler.

Göl Iplik Şeremet Tekstil Sanayi ve Ticaret A.S., another Turkish company, operates three factories that deliver a variety of highquality products, with a specialization in blended yarns. Investment in modern equipment and pioneering new products that expand its portfolio are at the heart of Göl Iplik’s success across almost four decades. Göl Iplik also tested the TC 30Si for man-made fibers in early 2024. This Trützschler customer took a close look at the TC 30Si during rigorous viscose trials. The TC 30Si achieved a 40 % higher productivity rate with the same level of quality, while consuming 15 % less power.

Fuze Technology Receives Updated EPA Approval for Antimicrobial, Product Lifetime Durability

Fuze Technology (Fuze) recently announced the Environmental Protection Agency’s (EPA) registration and approval for its products used in textiles and surfaces for antimicrobial effects, as well as lifetime durability of its application.

“This is huge news for Fuze and for the textiles industry,” said Andrew Peterson, Fuze CTO. “The EPA has reviewed our product and verified that it is an antimicrobial that is retained by the fabric for more than 100 washes. That is a first in the industry,” he continued.

The EPA’s approvals uniquely position Fuze in the market, making Fuze the only antimicrobial that can last the life of the textile it is applied to. Fuze uses its patented process to create its products that are applied to fabrics using various application methods.

In addition to its antimicrobial features, Fuze’s technology leads with its chemical-free, anti-odor capabilities which also promote moisture wicking and significantly faster drying times, while not disrupting the fabrics look or feel.

“Remarkably, we achieve these benefits using just 1mg per kilo of textile—a dosage nearly 1 million times less than any other antimicrobial treatments currently available,” Peterson mentioned. “This ultra-low application rate not only ensures minimal environmental impact but also maintains fabric integrity and performance over time,” he continued.

Fuze is a subsidiary of EVOQ, a science company that engineers novel products for life sciences, materials science, and textile science industries. The company’s multi-patented, high-volume laser fabrication process creates a product with consistent precise morphology, and no ion emissions under standard and stressed conditions. These properties represent a significant advancement in science with the potential for a wide range of applications.

Trelleborg Announces Investment in Rutherford County, North Carolina

Global engineered polymer group Trelleborg has announced a greenfield development for its engineered coated fabrics operations in Gateway West Commerce Park in Rutherford County, North Carolina.

The site, part of Rutherford County’s development vision for advanced manufacturing, will be Trelleborg’s second major facility in the area and is expected to cement Trelleborg’s position both as an industry leader and as a major local employer.

In addition to investments in state-of-the-art production capabilities Trelleborg will further invest in ensuring that the building and its operations are at the forefront of sustainability. The initial investment exceeds $30 million.

“By investing in sustainability as well as capacity, we will be better positioned to meet our customers’ needs and have a positive impact on our local community,” said Steve Brockman, President of Trelleborg Engineered Coated Fabrics. “Our new facility will be built to achieve LEED certification, and our operations will be carbon neutral and emit zero emissions. This investment helps us expand our use of bio-based polymers and recycled raw materials, aiding Trelleborg and our customers in meeting their product circularity targets.”

Trelleborg expects to break ground on the new facility in Q4 2024 and start production in Q1 2026.

New National Standard for Disposable Hygiene Products in China

China has released new national standard for disposable hygiene products (GB 15979-2024), which will be implemented from July 1, 2025.

The current national standard for disposable hygiene products in China has been used for 22 years. The last several years, more and more new hygiene products have been launched in the market. and testing techniques have also been improved accordingly. The new national standard updates definitions and categories of disposable products, adds new sanitary requirements for raw materials, and updates testing methods.

Fig.1 Launches Dissolvable Micellar Oil Wipes

Fig.1 has introduced dissolvable Micellar Oil Wipes. The wipes are derm-developed to melt away makeup and sunscreen, revealing clean, soft, radiant skin and individually wrapped for easy travel. Fig.1 partnered with skincare innovator Conserving Beauty to unite sustainability with beauty so consumers can enjoy a zero-trace cleanse. Each wipe dissolves within seconds in water, leaving zero waste and skin glowingly clean.

Fig.1 recommends dissolving the wipe in the shower or sink. Wipes that go into the garbage instead will biodegrade within 14 days.

INDA, NWI Announce Collaboration Agreement

INDA, the Association of the Nonwoven Fabrics Industry, and The Nonwovens Institute (NWI), announced a collaboration agreement to provide continuing education to the nonwovens industry. This agreement expands upon the ongoing partnership between INDA and NWI, whereby the two organizations have successfully presented training programs, covering the full spectrum of the nonwovens value chain from raw materials to processes to products.

Under terms of the agreement, INDA and NWI will develop and present a full roster of training courses, featuring a combination of classroom learning supported by hands-on activities in NWI’s world-class nonwoven production and testing labs on the Centennial Campus of North Carolina State University. The two organizations will also work together to explore additional educational programming to serve the needs of the nonwovens industry as they evolve over time.

“This collaboration agreement represents a significant next step in the partnership between INDA and NWI, as we build upon our training course offering to ensure it is meeting the needs of the nonwovens industry now and going forward,” said Matt O’Sickey, director of education and technical affairs at INDA. “We are also committed to pursuing new avenues to expand the knowledge base of professionals working in areas related to nonwovens.”

The current roster of INDA/NWI training courses include:

- Elementary Nonwovens

- Intermediate Nonwovens

- Fiber and Filament Extrusion Fundamentals

- Meltblown Technology

- Nonwoven Bonding Fundamentals

- Nonwoven Fabric Property Development and Characterization

- Nonwoven Product Development and Innovation

- Spunbond Technology

Course registration is open to INDA/NWI members and non-members. The INDA/NWI Short Course Value Pack program enables companies to purchase a block of registrations, which can be used by any combination of employees to register for any combination of training courses, at a discounted rate. Value Packs are available in bundles of 5, 10, 15, and 20 registrations, with discounts ranging from 10 percent to 25 percent, depending on the size of the Value Pack. For more information about the Value Pack program, visit https://thenonwovensinstitute.com/short-course-value-pack/.

Soft N Dry Tree Free Diapers Now in European Markets

Soft N Dry Diapers Corp. recently announced the launch of their innovative Tree Free disposable baby diapers in Europe, with sales and distribution capabilities in France, Germany, and the UK on a white label basis for retailers. Soft N Dry is market-ready at scale for its customers in the EU and complies with the EU Deforestation-Free Regulation (EUDR) era, which ensures disposable baby diapers sold in the EU do not cause deforestation and degrade the climate. Under the EUDR, diaper manufacturers using tree fiber must comply by January 1, 2025. As part of this strategic growth, the company has also appointed Alexander Valle Burkert as the new Chief Technology Officer (CTO), effective July 11, 2024.

Registration Is Open for RISE® 2024

Registration is open for RISE® 2024 (Research, Innovation & Science for Engineered Fabrics). Industry leaders will convene to discover cutting-edge nonwoven research and advancements, October 1-2, James B. Hunt, Jr. Library, North Carolina State University, Raleigh, NC. The theme for this year’s event is “Sustainability Solutions: Manufacturing More with Less.”

The RISE program will focus on these key topics:

- Disruptive Innovation & Enabling Technology

- Advancements in Natural & Bio-Based Fibers

- Sustainability in Chemistry

- Energy Efficiencies in Machinery

- Advanced Recycling Techniques & Methods

- In the News: Legislation & Regulation

Prior to RISE, continuing the program begun last year, there will be complimentary webinars featuring technology advancements and innovations. More details and topics will be announced at a later date.

The program highlights for RISE include:

- RISE® Innovation Award – three finalists will compete for the Award with the winner being announced Wednesday afternoon, October 2nd. Nominations may be submitted through July 29th via the INDA website: https://www.inda.org/awards/rise-innovation-award.html

- The Nonwovens Institute will host a tour of their $65 million-plus, 60,000 square-foot facilities featuring state-of-the-art equipment, pilot lines, and analytical laboratories on Tuesday, October 1st. An RSVP is required and space is limited.

- A Welcome Reception on Tuesday evening, October 1st, at the Lonnie Poole Golf Course.

- Graduate Student Poster session with their latest research during the Welcome Reception.

- New to RISE: Nonwoven Bonding Fundamentals course which will provide a detailed overview of the major fabric bonding processes used to make nonwovens. More details are available here: https://www.inda.org/training/advanced-training.php

- 18-hole Golf Tournament, Monday, September 30th, Lonnie Poole Golf Course, with a start time of 12 pm. Space is limited and registration is required.

TiHive won the 2023 RISE Innovation Award for their SAPMonit technology. TiHive’s innovation, SAPMonit – a technology breakthrough, inspects millions of diapers weekly. SAPMonit delivers lightning-speed inline inspection of superabsorbents’ weight and distribution, optimizes resources, detects flaws, and accelerates R&D. SAPMonit utilizes advanced see-through cameras, high-speed vision algorithms, and secure cloud integration, revolutionizing industry norms. SAPMonit has great potential for sustainability, cost reduction, and enhanced customer satisfaction.

ZymoChem Unveils World’s First Scalable, 100% Bio-Based, and Biodegradable Super Absorbent Polymer: BAYSE™

ZymoChem, a leading biotech company dedicated to creating sustainable materials for everyday products, announced the launch of BAYSE™, the world’s first scalable, 100% bio-based, and biodegradable Super Absorbent Polymer (SAP). This groundbreaking innovation is set to revolutionize the $145 billion global hygiene industry and pave the way for a more sustainable future.

BAYSE™ is a drop-in replacement for traditional, fossil fuel-based SAPs, which are a key component in disposable, absorbent hygiene products such as infant diapers. Unlike petroleum-derived, polyacrylate counterparts, BAYSE™ is made from renewable resources, maintains a lower carbon footprint, and is readily biodegradable, addressing the environmental concerns associated with the 300,000 diapers that enter landfills or are incinerated every minute.

ZymoChem’s proprietary technology platform enables the production of BAYSE™ at a cost which is competitive with traditional SAPs, ensuring that sustainability can be achieved without a premium. Intent on creating a positive environmental impact and inspiring change across sectors, ZymoChem’s BAYSE™ boasts additional applications in industries such as agriculture, cosmetics, and water treatment. The creation of microplastics from fossil-based petroleum SAP has been a concern for those industries, which BAYSE™ addresses as a high-performance, microplastic-free alternative.

ZymoChem recently raised $21 million in Series A funding to accelerate the commercialization of BAYSE™. For more information about ZymoChem and BAYSE™.

ANDRITZ to Supply Two Tissue Machines to C&S Paper, China

International technology Group ANDRITZ has received an order from C&S Paper to supply two PrimeLineCOMPACT tissue machines for its mill in Suqian City, Jiangsu Province, China.

The machines will produce tissue for household paper, napkins, handkerchiefs, facial tissues, and toilet paper at a maximum capacity of 94 t/d each. They have a design speed of 1,650 m/min and a width of 3.5 m.

Both machines will be equipped with suction pressure rolls with innovative roll covers and PrimeDry Steel Yankees for energy-efficient, high-quality production. The scope of supply also includes under-machine pulpers and flow and consistency transmitters for both lines, as well as PrimeControl automation systems for efficient control and monitoring of the entire production process.

C&S Paper Co., Ltd., is one of China’s largest household paper producers, with C&S and Sun as its two main brands.

This order once confirms ANDRITZ’s strong market position as one of the leading suppliers of machines and systems for the Chinese tissue industry, and ANDRITZ’s expertise specifically in high-quality and resource-saving components.

Lenzing introduces new Black Towel Collection

Lenzing Group, a leading global producer of wood-based specialty fibers, announced the launch of its latest Black Towel Collection made with LENZING™ ECOVERO™ branded black viscose fibers and TENCEL™ branded black modal fibers. The collection features six essential everyday washable and reusable face and body care items, from makeup removal pads, makeup removal towels, gym towels, bath towels, hand towels, hair bonnets, to beach towels, designed to cater to the ever-changing consumers’ needs for quality, responsible personal care items for every aspect of daily life. Made with ingredients that are responsibly produced, the Black Towel Collection presents an alternative choice for a societal norm where conventional makeup removal products are mostly single-use disposable items, and reusable towels often get stained or discoloration due to repeated usage. The collection will bring about a refined experience to consumers through its exceptional durability, softness and color vibrancy.

The Black Towel Collection is woven with a blend of cotton and TENCEL™ Modal black fibers or LENZING™ ECOVERO™ Viscose black fibers with a unique fabric composition to enhance durability. Even after multiple washes, these products retain their softness and gentle feel on the skin, making them ideal for repeated use. Derived from controlled or certified wood sources, these specialty fibers are made from resource-saving processes, using at least 50% less carbon emissions and water consumption. Additionally, the LENZING™ ECOVERO™ Viscose black fibers are certified biodegradable and compostable at the end of their lifecycle. Both reusable and responsibly produced, this towel collection is an excellent solution for individuals looking to minimize the carbon footprint1 of their everyday care practices.

Kimberly-Clark Sells its Assets in Bolivia to Empacar

Kimberly-Clark has sold its assets in Bolivia, according to a statement reported by several news sources. The company said the sale to Empacar came after “thorough and thoughtful analysis” and included Kimberly-Clark’s plant in Santa Cruz de la Sierra where it produced brands Huggies, Kleenex, Scott and Kotex as well as its K-C Professional industrial hygiene products.

The sale ended Kimberly-Clark ’s 25 years of operations in Bolivia. The terms of the sale are not known.

Mann+Hummel Launches Nanofiber-Based Cabin Air Filter

Mann+Hummel has launched Mann-Filter FreciousPlus featuring nanofibers for cabin air filtration. The new filter is designed to effectively filter ultra-fine particles, along with pollutants from both outside and inside the vehicle, and it also offers proven protection against allergens, bacteria, and mold.

In recent years, international studies have proven the impact of the smallest particles on our health: The smaller the particles, the more dangerous they are, as they can penetrate deeper into the human respiratory system and cause serious health problems, including death. With the evolved FreciousPlus featuring nanofibers, MANN-FILTER sets new standards in cabin air filtration. The new filter not only impresses with its filtration of ultra-fine particles, but also with the filtration of pollutants both from outside and inside the vehicle. The new filter continues to offer proven protection against allergens, bacteria, and mold.

Mann+Hummel has been successfully using nanofiber technology to filter out the finest particles for a number of years, and it is this technology that is now available on the automotive aftermarket for premium brand Mann-Filter cabin air filters. Since January 2024, these have been available in the form of the Mann-Filter FreciousPlus FP 38 004 for the BMW 5 Series and 7 Series saloons, and now feature in the 5 Series Touring wagon, too.

“Our Mann-Filter FreciousPlus FP 38 004 has the finest nanofibers, which are about 100 times thinner than the fibers of conventional filter linings,” said Thomas Heininger, director Engineering Cabin Air Filters at Mann+Hummel. “These fibers form a spider’s web-like structure over the other filtration layers with coarser fibers, enabling them to capture ultra-fine particles. This means that, in addition to the PM10 and PM2.5 particles, the FreciousPlus featuring nanofibers can remove 90% of the even finer PM1 class i.e. particulates with an aerodynamic diameter of less than 1 micrometer (0.0001 cm). The nanofibers in the FreciousPlus filter up to 80% of ultra-fine particles (UFP) smaller than 0.1 micrometers, thus achieving maximum values. For context, these extremely small particles are about 700 times smaller than a human hair.”

The extremely thin nanofiber ensures that the FP 38 004 is resistant to humidity and temperature fluctuations and provides consistently high filtration throughout the entire service interval. To ensure that the FreciousPlus cabin air filter with nanofibers can work reliably, it must be replaced once a year or every 15,000 kilometers. “We recommend that local experts regularly inform vehicle owners of the importance and benefits of the cabin air filter. Most car drivers are unfortunately unaware of this,” says Heininger.

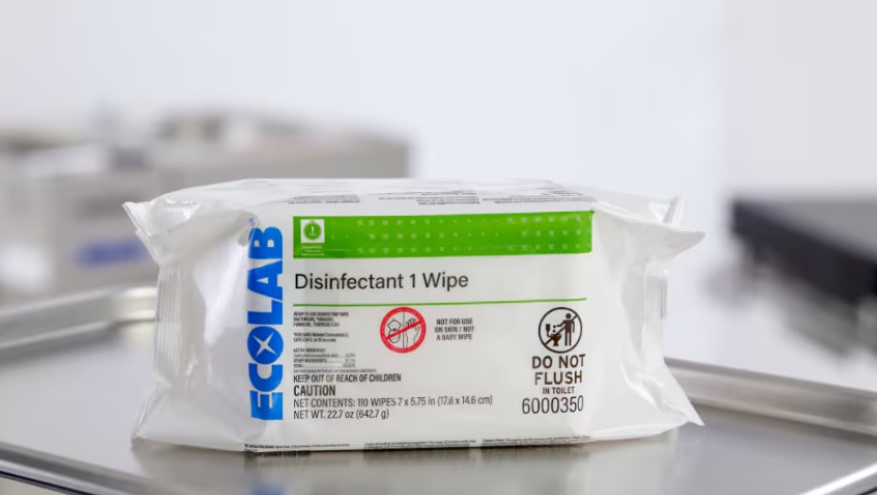

Ecolab Launches 100% Plastic-Free Wipe for Healthcare Settings

Ecolab has launched Disinfectant 1 Wipe, the First EPA-Registered 100% plastic-free readily degradable disinfectant wipe complete with 1-minute hospital disinfection. The new product supports healthcare facilities looking to help improve patient safety and achieve their sustainability goals. The development comes from an urgent need to address the environmental impact of traditional single use plastic-based disinfectant wipes, which currently dominate the North American market and take hundreds of years to degrade once discarded.

On the sustainability side, the Disinfectant 1 Wipe boasts exciting degradation capabilities, reaching 94.3% relative biodegradation in a 15-day accelerated test, demonstrating full decomposition into non-hazardous byproducts.

Ansell Completes Acquisition of Kimberly-Clark’s PPE Business

Ansell Limited, a global leader in protection solutions, announced it has successfully completed the acquisition of Kimberly-Clark’s Personal Protective Equipment (KCPPE) business. This strategic acquisition strengthens Ansell’s position as a global leader in personal protection solutions, expands its product portfolio, and enhances its service capabilities to meet customer needs across industries and geographic markets.

As part of this agreement, Ansell will acquire the Kimtech™ brand of scientific PPE for customers in laboratory and cleanroom environments and the KleenGuard™ brand of safety PPE for customers in industrial environments. In addition, Ansell will add two new capabilities to its Ansell Services portfolio: The RightCycle™ Program, a sustainable solution for the disposal of non-hazardous personal protective equipment (PPE) waste, and APEX™, a best-in-class approach to cleanroom customer change management and contamination control.

Neil Salmon, CEO of Ansell, expressed his enthusiasm for the acquisition, stating, “This acquisition represents a significant milestone for Ansell, and we are excited to welcome the KCPPE team to our organization. The KCPPE business is renowned for its high-quality brands, innovative portfolio, and strong customer relationships. Integrating their expertise and product knowledge enhances our ability to provide customers with comprehensive, world-class safety solutions.”

Rob Hughes, Senior Vice President and General Manager of the newly created Kimtech™ and KleenGuard™ Business Unit (KBU), shared his thoughts on the acquisition, saying, “Joining forces with Ansell is a tremendous opportunity for our business and employees. Ansell’s commitment to safety and innovation aligns perfectly with our values. Together, we will continue to deliver exceptional protection solutions for workers across different industries – worldwide.”

As part of a transition services agreement, Kimberly-Clark Corporation will support the KCPPE business over the next year to allow sufficient time for a successful integration into Ansell. During this transition period, customers can continue to request Kimtech™, KleenGuard™, The RightCycle™ Program and APEX™ products and services from Kimberly-Clark Professional. Customers will be notified promptly when Ansell can begin taking orders.

Freudenberg Apparel Launches Complete RCY 99xx

Freudenberg Performance Materials Apparel recently announced the global launch of the complete RCY 99xx series recycled polyester (rPET) shirt interlinings. This innovative product line serves as a sustainable counterpart to Freudenberg’s renowned 95xx series, which has been a staple in the industry for over twenty years.

The 95xx series, celebrated for its unique bi-elastic properties, has earned its place as one of Freudenberg’s most sought-after shirt interlining ranges worldwide. Cherished by customers across the globe, the 95xx series has consistently delivered on quality and performance.

Now, taking a leap towards sustainability, Freudenberg introduces the complete RCY 99xx series. Crafted from rPET, these bi-elastic interlinings are designed to complement an array of contemporary fabrics, including pure cotton, T/C, flannel, oxford, cotton & linen blends, seersucker, jersey and all types of stretch knits. The RCY 99xx series not only preserves the natural hand feel, texture, and shape of these fabrics but also infuses a fresh creative dimension into shirt design.

The RCY 99xx series boasts an impressive weight range of 30-150 g/m2, offering versatility for a diverse spectrum of shirt styles, from men’s casual shirts and women’s blouses to polo shirts, sports shirts, and even denim shirts. This adaptability ensures that designers and manufacturers have the flexibility to meet the evolving demands of the market while upholding sustainability principles.

Nice-Pak to Close Germany Plant

Nice-Pak International has announced the closure of its production facility in Osterweddingen, Germany. NPI, a subsidiary of U.S. based Nice Pak Products, will absorb German production in its U.K. plants in Flint and Wigan.

Nice-Pak is coming off a very strong year globally, according to reports, but as it reviewed plans for the future as well as changing market conditions, it became apparent that its U.K. plants are better positioned to compete in both the U.K. and continental Europe.

Indorama Ventures Secures $200 Million Loan to Drive Sustainability Program

Indorama Ventures, a global sustainable chemical producer, announced it secured a new 7-year loan totaling $200 million from the International Finance Corporation (IFC) to help fund the continued growth of the company’s strategic sustainability programs in India, Thailand and Indonesia, and promote a circular economy as the world’s leading PET recycler.

The loan from the IFC, which is a member of the World Bank Group focused on private sector development in emerging markets, provides flexibility to convert into a sustainability-linked facility based on mutually agreed sustainability targets in the future. The funds will be used to finance sustainability initiatives that bolster Indorama Ventures’ leading strategic footprint in PET recycling. These also include enhancing efficiency at the company’s existing recycling facilities at Nakhon Pathom and Rayong in Thailand, launching a state-of-the-art plant in Karawang in Indonesia, and establishing new recycling plants in India. Additionally, the financing will reimburse costs incurred in 2023 and 2024 for sustainability projects.