In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant to our industry from manmade to natural to bio-based fibers, innovations in nonwoven, woven, braided and technical textiles, technologies for additives, bonding, coatings and polymers, and applications from apparel to hygiene to transportation, and more. Here we will post news stories relevant to textile fibers and their downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg at ken@ifj.com.

Most recent update: January 28, 2025

Americhem Expands Research and Development Capabilities in India

Americhem, Inc. announced the opening of a new research and development center in Silvassa, India. This new facility, located at Olive Industrial Park, will enhance Americhem’s ability to provide faster and more localized service to customers throughout India and Southeast Asia. The 4000 square feet center will offer specialized testing services for masterbatch color development, particularly for melt spinning and textile manufacturing customers. Additionally, it will provide field and technical services to support customer-specific requirements.

The new laboratory aims to help Americhem expand into new markets and areas of business by offering enhanced capabilities for custom color matching and faster response times. This will attract new customers and industries that prioritize speed and efficiency in their supply chain.

S. Mani, Managing Director for India and Southeast Asia, emphasized the company’s long-term commitment to the region. “This investment demonstrates Americhem’s dedication to fostering innovation, expanding capabilities, and supporting customers as they grow alongside these dynamic markets,” said Mani.

Toshan Simaiya, Americhem’s Operations Director for India, highlighted the benefits of the new center, noting that it will allow the company to be closer to customers, provide nimble support, faster color development, and enable real-time communication and approvals. The center will be led by Sandeep Bhamare, Head of R&D – Fibers for Americhem’s India, who will ensure smooth collaboration between Americhem’s Pune site and the new facility. Krunal Bodne, Head of Sales and Marketing Textiles/Fibers, emphasized the benefits for customers, stating that they are welcome to the lab to get the match done on the same day, enabling speed to market.

The research and development center began operations in late 2024 and is strategically situated just 5 km from Bhilad Highway NH-48, with future access to the Mumbai-Delhi Expressway.

Monadnock Nonwovens Enhances Meltblown Material

Monadnock Non-Wovens LLC, a manufacturer of meltblown synthetic media for the automotive, respirator, surgical face mask, and air and liquid filtration markets, has invested in technology to deliver higher efficiency meltblown media for air filtration. The new enhanced filter media, Monadnock HPAQ 3F, is engineered specifically for respirators, HVAC and air purification filters. HPAQ 3F will meet all international filtration standards: ASHRAE 52-2, ASTM 2100, EN-149, HEPA, MERV 10-16, and NIOSH.

Filters made with Monadnock HPAQ 3F will capture more dust, pollen, allergens, viruses, and smoke with lower pressure drop than traditional polypropylene and other synthetic meltblown media.

“Bringing this new capability to our manufacturing facility enables us to produce materials that help meet global air filtration standards,” said Jim Cree, MNW president. “In a time with forest fires and airborne diseases, we are offering the filtration market a healthier solution that is made right here in the United States.”

HPAQ 3F is available in rolls up to 95” / 2.4 m wide. This virgin polypropylene (PP) product is recyclable, and trim waste can be repurposed in sorbent applications. As with all MNW products, it is made with 100 percent renewable wind-powered electricity (Green-e certified RECs).

Indian Technical Textiles Startup Raises $4.2m Seed Funding

Whizzo, a Bengaluru, India-based startup specializing in engineered and technical textiles, has raised US$4.2 million in a seed funding round led by Lightspeed, with participation from Beenext.

The funding will be used to enhance research and development in materials science.

It will also help establish a design lab and strengthen supply chain infrastructure in India, Vietnam, China, Bangladesh, and Indonesia.

Founded in 2024 by Shrestha Kukreja, Whizzo creates customized textile blends using woven, nonwoven, and composite technologies for various industries.

The company is currently working with over 25 clients and plans to expand its customer base to over 100 in South America, West Asia, Africa, Europe, and Japan.

Michelman Provides Sizing Support for FibreCoat’s Basalt Fiber

Michelman, a global developer of advanced materials, has collaborated with FibreCoat, a high performance materials company based in Aachen, Germany, to support the launch of FibreCoat’s aluminum-coated basalt fiber.

This new fiber, AluCoat, was developed by FibreCoat to address the need for lightweight, conductive materials in applications such as electromagnetic interference (EMI) and radio-frequency interference (RFI) shielding, as well as thermal management for electric vehicles, consumer electronics, and energy storage.

Michelman’s Hydrosize® fiber sizing technology plays a critical role in enhancing the performance and processability of FibreCoat’s fiber for composite manufacturing. FibreCoat’s patented aluminum-coating process partially or fully coats basalt fibers, combining the material’s mechanical properties with aluminum conductivity. By integrating Michelman’s Hydrosize® fiber sizing, the aluminum-coated fibers achieve key performance attributes necessary for reliable composite applications.

Michelman’s sizing helps form stable fiber bundles, reducing fuzz and maintaining fiber integrity during processing, and supports weavability, making continuous fibers more spreadable. Additionally, the sizing ensures compatibility with the resin systems, and balances compatibility between the aluminum and basalt surfaces on the fiber.

Courtney Harold Joins Green Theme Technologies As Head Of Marketing

Green Theme Technologies (GTT) announced the appointment of Courtney Harold as Head of Marketing. With over 25 years of experience in the textile, apparel, and footwear industries, Courtney brings a proven track record of transforming complex challenges into clear, actionable strategies that drive growth and product innovation.

“I am thrilled to join GTT and help lead the initiative to bring EMPEL’s innovative, water-free, and PFAS-free DWR technology to market,” said Courtney Harold. “GTT’s commitment to surpassing industry standards is precisely the challenge fueling my passion for solving complex problems.

I look forward to spearheading the marketing initiatives to position EMPEL as the leading brand in the DWR sustainable performance fabrics.”

As GTT continues to dominate the water-free and sustainable DWR space, Courtney’s expertise in brand building, market entry strategies, and product innovation will be instrumental in positioning EMPEL for continued growth and success.

NCTO welcomes President Trump’s ‘America First Trade Policy’

The National Council of Textile Organizations (NCTO), representing the full spectrum of U.S. textiles from fiber to finished sewn products, issued the following statement from President and CEO Kim Glas regarding President Donald Trump’s executive order, the “America First Trade Policy.”

“We welcome President Trump’s executive order directing federal agencies to conduct a comprehensive review of the devastating impact of unfair trade practices by China and other countries that have undermined U.S. textile manufacturers, the broader manufacturing base and the economy.

“In the past several months alone, the U.S. textile industry has seen 26 plant closures and thousands of layoffs.

“We look forward to working closely with the President and his administration to implement much needed reforms to U.S. trade policy. Policies such as penalty tariffs on China and comprehensive de minimis reform are essential to addressing the actions of predatory exporters and bad actors that threaten our strategic industry, displace our workers, damage our economy and harm U.S. consumers,” Glas said.

Acme Mills Unveils “Natura” Bio-Based PLA Fabrics

Acme Mills Company, a global leader in textile innovation, recently introduced Natura, its groundbreaking line of bio-based polylactic acid (PLA) fabrics. Designed to replace petroleum-based nonwovens such as PET, PP, and Nylon, Natura represents a revolutionary step toward reducing environmental impact without compromising performance or quality.

The Natura product line includes a diverse range of PLA fabric types, such as spunbond nonwovens, needled felts, hydroentangled, and melt-blown textiles. These innovative materials are tailored to meet the demands of industries including food and beverage, packaging, automotive, furniture, healthcare, and filtration.

“Natura is more than just a product line; it’s a testament to our commitment to innovation and sustainability,” said Matt Utley, Chief of Strategy. “By offering a bio-based alternative to petroleum-based textiles, we are empowering industries to make environmentally responsible choices without sacrificing performance.”

Natura fabrics are crafted from renewable resources such as corn starch and sugarcane, and they are biodegradable under industrial composting conditions. Drawing from sustainability insights by industry leaders like NatureWorks, Natura fabrics significantly reduce greenhouse gas emissions and fossil fuel consumption compared to traditional plastics.

Valmet Introduces Roll Cover for the Nonwovens Process

Valmet is launching a new long-lasting rubber roll cover to better serve its customers in the textile industry. The new Valmet Nonwovens Roll Cover WN has an exceptional cover structure design and excellent mechanical, dynamical, and chemical resistance properties, providing a long operation time and stable nip condition in the demanding nonwovens process conditions.

“In addition to its excellent heat, wear, and chemical resistance properties, the Valmet Nonwovens Roll Cover WN provides stable nip behavior and hardness stability. Its premium bonding system leads to long service intervals, thus, together with the extra-long running time, improves the operational efficiency of the chemical press and decreases the operational costs,” says Ulla Kanerva, Global Technology Manager, Roll Covers and Maintenance at Valmet.

Originally, Valmet Nonwovens Roll Cover WN was developed to resolve a customer challenge.

“Our customer operating in the nonwoven business in the textile industry was experiencing excessive amounts of lost production time and high costs for roll recovering due to the limited life span of their current roll cover. With our tailored solution, Valmet Nonwovens Roll Cover WN, the customer has now been operating for a year without any issues, leading to enhanced productivity, reduced costs, and improved process efficiency. We are proud to have helped the customer in their challenging situation and happy for the repeated order we recently got,” said Anuchit Kamlangdee, Product Manager, Roll and Workshop Services, Southeast Asia region at Valmet.

Leigh Fibers to End Nonwovens Production Amidst Restructuring

Leigh Fibers has decided to idle a nonwovens line in Wellford, South Carolina as part of a restructuring plan aimed at further integrating its businesses with ReVive Fiber which it purchased last year. In addition, the plan calls for the consolidation of the company’s operational footprint, a renewed focus on its core competencies and streamlining of its internal structure to position the company for profitable, long-term growth.

Leigh Fibers will retain a small presence in Wellford after consolidating the majority of this operation into ReVive Fiber’s facility, in Spartanburg. All office staff will be relocated to ReVive’s offices in Spartanburg. The Brownsville, Texas facility will continue to operate as is without any lost production capabilities.

The company’s focus in the future will be on its engineered fiber business, global trading business and continued leadership in the second life and sustainability efforts being put into diverting post-consumer textile waste from landfills.

Drake Purchases PureCycle Resin Following Successful Production of Continuous Filament Yarns

PureCycle Technologies, Inc. announced the initial sale of nearly 500,000 pounds of resin to Drake Extrusion Inc. for the production of continuous filament yarns, which could be used to make items such as rugs, upholstery, and apparel. Drake is North America’s leading manufacturer of colored filament yarn, and staple fiber.

The agreement comes after Drake’s successful production of continuous fiber using a compound that includes PureCycle’s PureFive™ resin. The resin was produced at Ironton, Ohio from 100% post-consumer recycled (PCR) feedstock and then developed into a compound by PureCycle’s Research & Development team in Durham, North Carolina.

Approximately 20% of the global virgin polypropylene (PP) supply is used for fiber and yarn. Until now, there has not been a reliable recycling alternative to replace virgin PP due to the complexity of the fiber manufacturing process. Polypropylene fiber is preferred for its light weight, durability, moisture and chemical resistance.

Ocean State Innovations (OSI) Announces Strategic Partnership with Murdock Webbing Company

Ocean State Innovations (OSI) and 1947 LLC announced their new partnership with Murdock Webbing. OSI and 1947 will be the exclusive international distributors of Jacquard-woven MultiCam® webbing.

Murdock Webbing is the only Crye Precision approved and licensed source for Jacquard woven MultiCam®. As part of the Jacquard-woven process, Murdock utilizes pre-colored yarns. Why is that important? This means all Murdock Jacquard-woven MultiCam® products are “two sided” – without a hefty “two sided” upcharge. Because the color is applied to yarns prior to weaving, the pattern runs all the way through the webbing. Unlike printed product, the pattern is not lost to wear and abrasion over time and use. Murdock Jacquard-woven MultiCam® means quality and value.

“We’re proud to represent Murdock Webbing’s MultiCam® Jacquard webbing on an international scale, delivering a premium product that ensures customers receive the quality and authenticity they require in the iconic MultiCam® pattern” said Ben Galpen, Co-Founder of 1947LLC and OSI partner.

Big Agnes Launches HyperBead Fabric Technology

Colorado based Big Agnes, a leader in innovative outdoor equipment, announced its next evolution in sustainable ultralight equipment with the launch of its revolutionary HyperBead™ fabric technology. Embodying the brand’s commitment to performance, sustainability and adventurer-first design, HyperBead represents the next step in outdoor gear innovation, elevating some of the brand’s most popular tents. The technology addresses core challenges faced by outdoor enthusiasts while setting a new standard for tent fabric innovation.

Breakthrough Performance Highlights:

- 25% More Waterproof: Exceeding traditional ultralight fabric performance without relying on harmful chemicals – offering permanent water repellency that doesn’t degrade over time

- 6% Lighter: Reducing weight with enhanced durability, so adventurers can focus on their journey, not their load

- Environmentally Conscious: No intentionally added PFAS. No DWR or WR treatments

“We’ve spent two years sweating over every ounce and every detail of this process and technology,” said Michael Thompson, director of design and development at Big Agnes. “HyperBead is a complete reimagining of ultralight gear – a technology that performs better, weighs less and is easier on the environment. This fabric is the culmination of that vision.”

Grand Opening of the Fibroline USA Innovation Lab

Fibroline, the French company that developed dry powder impregnation solutions, and Navis TubeTex, a US-based leader in machinery manufacturing, are launching a new innovation lab in Lexington, North Carolina. This laboratory will bring new expertise and resources to the U.S market for dry impregnation solutions. The inauguration is set for February 11, 2025.

After having officialized a strategic partnership in January 2024, Fibroline and Navis TubeTex are now ready to launch the Fibroline USA Innovation Lab, a new state-of-the-art laboratory that will help them provide customers with unparalleled support and cutting-edge technologies. This facility marks the beginning of a transformative journey in creating the next generation of advanced textiles. “This new lab is a hub for collaboration and ingenuity,” Will Motchar said, President & CEO of Navis TubeTex. “It is designed to explore, test, and bring to life groundbreaking textile solutions that meet evolving market demands.”

The opening of this new location will allow Fibroline to collaborate directly with its partners all over the Americas. “This innovation lab is an important step for Fibroline’s worldwide development, as our technologies are now directly and easily accessible to North American partners,” Jerome Ville commented, CEO of Fibroline. “We had been wanting to extend our presence here, and this partnership between Navis TubeTex and Fibroline perfectly fits with our strategy to bring both more performing and eco-friendly solutions to the textile industry.”

Reclaimed Cleaning Textiles Acquires United-Southern Waste Material Company

RTCM Holdings, Inc.’s Reclaimed Cleaning Textiles, announced the purchase of United-Southern Waste Material Company (USW), a Dallas-based textile recycling and repurposing company. The transaction will establish the largest textile recycler in North Texas.

Founded in 1914, USW specializes in the recycling and repurposing of clothing and wiping rags, which are sold across global and domestic markets, respectively. The company has built a reputation as a highly respected organization in the space, expanding in recent years to collect its own credential, with over 120 bins. USW currently operates out of an 88,000 square foot facility. Co-owner and third-generation family member Mindi Levine Kahn will remain with the business to provide her expertise and ensure continuity throughout the integration.

“Our stated vision is to divert 100 million pounds of textiles from landfills on an annual basis as part of our commitment to make a difference in the world,” said Craig McAndrews, President and CEO of Reclaimed Cleaning Textiles. “USW’s operation will help us expand our capacity and drive essential long-term growth. Mindi and her family have been pioneers in the second-hand clothing industry, and we are excited to come together to create a best-in-class regional operation.”

“Reclaimed Cleaning Textiles has long been a leader in the recycled textiles space, with a focus on sustainable profitability,” said Mindi Levine Kahn. “This next chapter will offer customers, suppliers, and employees enhanced resources in an evolving market.”

Wyrick Robbins Yates & Ponton LLP served as legal counsel for Reclaimed Cleaning Textiles, and Haynes and Boone, LLP served as legal counsel for USW. Financial terms were not disclosed.

LENZING™ Lyocell Fill Expands Portfolio

The Lenzing Group, a leading supplier of regenerated cellulosic fibers for the textile and nonwovens industries, announced the expansion of its LENZING™ Lyocell Fill portfolio within the TENCEL™ family of fibers.

This broader portfolio expansion introduces a finer variant with various cut lengths, tailored for filling applications in home textiles and apparel.

Featuring two distinct linear densities and various cut lengths, the expanded fiber portfolio offers enhanced compatibility to blend seamlessly with other filling fibers like polyester, and filling materials like down. This versatility supports different filling technologies and product constructions, catering to diverse design and application needs and specific consumer preferences in home textiles, apparel and beyond.

The new, finer fibers, suitable for not only carding but blow-fill technology, enhance the sensorial experience in pillows, stuffed toys, and other lightweight applications. Meanwhile, the established, coarser fibers continue to deliver inherent moisture control and bulkiness for enhanced sleep comfort in comforters, quilts, and other home textile applications, particularly those using carding technology.

Hohenstein, Under Armour, PPT Group Develop Standard for Microfiber Discharge

Building on a rapid test for the detection of microfibers in sample water presented in 2023, the sporting goods manufacturer Under Armour, together with the testing service provider Hohenstein and the measuring device provider PPT Group, has published a standardized test method that enables the determination of microfiber release from textiles under simulated washing conditions. With the help of the new DIN SPEC 19292, apparel/textile companies along the value chain are now able to measure and (e.g. comparatively) evaluate the extent of fiber release of different materials as part of their product development.

During the manufacture and use, but also during the care of textile products made from synthetic materials, fibers are released into the environment and pollute the oceans as microplastics, for example. Depending on the washing program selected, i.e. the temperature and mechanical load, different quantities of textile fibers end up in the wastewater, even when washing items made from natural fibers. This is where the DIN SPEC 19292 test procedure comes in: After a simulated washing process of a fabric sample using tabletop equipment and a defined amount of water, the sample water is filtered and based on a visual evaluation with a microscope, the degree of fiber fragmentation by the textile material is determined.

In addition to working on the new DIN SPEC 19292, Hohenstein also offers further tests to determine the extent to which (micro)fibers degrade in the wastewater of production plants or in household laundry and how harmful the fiber residues are to the environment. The tests are carried out according to Hohenstein’s in-house methods as well as international standards and procedures.

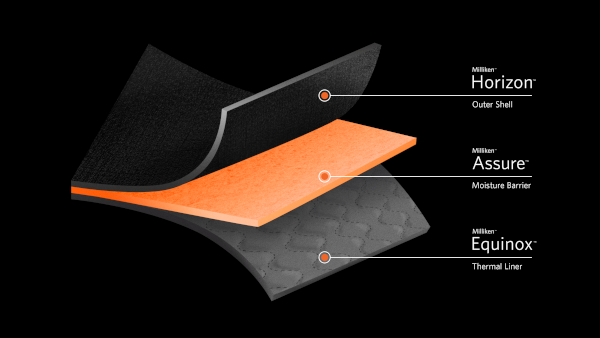

Milliken Offers Non-PFAS Materials for Firefighter Gear

Milliken & Company announced that it is the first textile manufacturer to offer non-PFAS materials for all three layers of firefighter turnout gear, including outer shell, thermal liner, and moisture barrier. Access to all three layers from a single U.S.-based supplier allows garment manufacturers to test the fabrics as a system while ensuring a complete chain of custody for the material — which can minimize delays and get gear into the hands of firefighters faster.

Milliken is the only U.S. manufacturer offering non-PFAS fabric for every layer of turnout gear, but more importantly, we’re proud that these fabrics exceed performance standards,” said Marcio Manique, SVP of Protective Fabrics for Milliken. “Our team is passionate about helping to protect first responders, and our certification results prove that firefighters don’t have to compromise on health, protection, or comfort when choosing the right turnout gear.”

The three layers in the non-PFAS composites include:

- Milliken Horizon™: a non-PFAS, lightweight outer shell that provides industry-leading retention of strength and appearance year after year.

- Milliken Assure™: a non-PFAS, non-halogenated, flame-resistant moisture barrier that exceeds NFPA 1971-2018 requirements.

- Milliken Equinox™: a non-PFAS, slick thermal liner that offers superior wicking and moisture management, resulting in quick dry times and high levels of comfort and protection.

The recently published NFPA 1970-2025 standard was issued with reduced performance criteria in anticipation of non-PFAS products having poorer performance; however, the Milliken composites were able to meet and exceed the more stringent NFPA 1971-2018 standard during the third-party testing process in November. Every individual layer that make up both composites are UL certified.

States such as Massachusetts and Connecticut have already passed bans on the use of PFAS in firefighters” protective equipment beginning as early as 2027. Milliken’s composites are the only high-performing, non-PFAS, non-halogenated FR options readily available on the market today. The company eliminated the use of PFAS chemistry from its fire service fabrics in 2021, and across its entire textile fibers and finishes portfolio in 2023.

www.milliken.com

Intercare And Kimberly-Clark Forge Strategic Partnership To Transform Hygiene Standards Across UAE, Qatar, And Oman

Intercare Limited, a leading provider of hygiene and cleaning solutions in the Middle East, announced a landmark strategic partnership with Kimberly-Clark Professional, a global leader in hygiene products and workplace solutions. This collaboration aims to revolutionize hygiene standards across the UAE, Qatar, and Oman markets.

The partnership combines Intercare’s deep-rooted regional expertise and distribution network with Kimberly-Clark’s world-renowned product portfolio, which includes trusted brands such as Kleenex®, Scott®, WypAll®, Kimtech™. This alliance will provide businesses and institutions across the region access to premium hygiene solutions that meet the highest international standards.

ATEX USA Acquired by BCNonwovens

European producer of spunlace roll goods BCNonwovens has acquired the shares of specialty nonwovens manufacturer Atex USA from EOS Investment Management Group, an independent asset manager with operations in London/UK, Luxemburg and Milan/Italy.

Atex USA Inc., based in Gainesville, Georgia, is recognized for offering specialized nonwoven products to an extensive customer base which extends across the USA and selected export markets. BCNonwovens S.L., based in Barcelona, Spain, is a leader in the production of spunlace roll goods, catering primarily to the fast-moving consumer goods (FMCG) sector, offering products such as premoistened wipes and hygiene articles. The company also extends its products to the medical sector as well as specialty goods market. The acquisition of Atex USA underscores BCNonwovens’ ongoing expansion efforts to bolster its global market presence.

Nordifa Acquires Sporda Nonwovens in Sweden

Swedish manufacturer of technical textiles Nordifa, has acquired Sporda Nonwoven, a maker of thermobonded and needlepunched nonwovens, which is also based in Sweden.

Sporda declared bankruptcy on November 18, 2024. The acquisition by Nordia is helping the company continue operations and retain employees. It will continue to be run as an independent company led by current executives Jonas Rylander and Anna Hallberg.

“The goal is to continue as before with the same focus and the same customers,” says Rylander. “Our owner Nordifa is not planning any changes in the near future, but in the long term we see some opportunities to achieve synergy benefits, for example in material supply and technical development.”

Nordifa executives did not describe the companies as competitors but said they complement each other. The acquisition of Sporda Nonwoven broadens and deepens its offering to both new and existing customers across a number of markets including filtration, acoustics and insulation materials.