In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant to our industry from manmade to natural to bio-based fibers, innovations in nonwoven, woven, braided and technical textiles, technologies for additives, bonding, coatings and polymers, and applications from apparel to hygiene to transportation, and more. Here we will post news stories relevant to textile fibers and their downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Matt Migliore at mmigliore@inda.media.

Most recent update: January 28, 2021

The Fiber Year announces new monthly service tracking Pakistani textile market

The Fiber Year teamed up with local Pakistani textile experts to offer a new monthly update on Pakistan’s textile chain. Pakistan has been among the top cotton suppliers with an average annual volume of almost 2 million tonnes during the 2010s.

A complimentary copy of the first issue is available on the website www.thefiberyear.com. If you would like to subscribe to this new monthly service, please visit The Fiber Year shop. Regular price is CHF550 for an annual subscription, and for 2021 there is a discount of 10%.

Source: thefiberyear.com

HeiQ launches HeiQ Viroblock Permanent

Swiss textile innovator HeiQ announced the launch of HeiQ Viroblock Permanent, a new innovation under the HeiQ Viroblock technology platform. HeiQ Viroblock Permanent is being used exclusively on Meryl Skinlife Force, a new sustainable, antimicrobial and durable premium fabric.

Meryl Skinlife Force has been developed in partnership with Spanish fiber manufacturer Nylstar SL, a pioneer in hydrogen technology in high-tech yarn production, and a long-term customer of HeiQ.

HeiQ supplies a blend of manufactured raw materials for the fabrication of Meryl Skinlife Force powered by HeiQ Viroblock Permanent.

While the company’s current HeiQ Viroblock offering is achieved by chemical treatment to a finished fabric, HeiQ Viroblock Permanent is embedded inside the fiber, meaning that the effect lasts for at least 100 washes, instead of the current 30 (which is already market leading). This opens up new markets to HeiQ due to its suitability for use in medical environments with high hygienic and sanitary requirements. It is also 100% recyclable, putting HeiQ and Nylstar at the forefront of circular economy.

Source: heiq.com

Johns Manville launches glass fiber recycling unit in Slovakia; capable of processing 3 tons per hour

Johns Manville (JM), a leading manufacturer of continuous filament glass fibers, announced the successful launch of a thermal recycling unit for waste glass fibers in its Engineered Products plant in Trnava, Slovakia.

“The primary goal of this investment is to achieve a tangible positive environmental impact by drastically reducing the landfilling of glass fiber waste,” said Elena Hrivikova, Johns Manville’s manager for Environment, Health and Safety – Europe/Asia. “This project is part of our response to the European Commission’s zero waste program and our overall target for sustainable management of the planet’s natural resources.”

The new Trnava unit has a projected recycling capacity of more than 3 tons per hour and consists of a warehousing area, feeding and transportation equipment, shredder, burning chamber and milling. After processing, the recycled glass powder is free of organic particles and refed as raw material into the glass production process on-site, thus achieving a closed production loop. According to Johns Manville’s estimate, the project will keep more than ten thousand tons of waste out of the landfill each year; that’s one large truck every day.

Source: jm.com

Kraig Biocraft and Kings Group in joint venture

Kraig Biocraft Laboratories, Inc., the biotechnology company focused on the development and commercialization of spider silk, announced that it is forming a joint venture partnership with MtheMovement, an eco-friendly luxury streetwear apparel line, part of the Kings Group of Companies.

The joint venture will develop and sell Kraig Labs’ spider silk fibers under the new innovative apparel and fashion brand, trade named SpydaSilk™ and potential other trademarks to be announced. All intellectual property related to SpydaSilk™ will be jointly owned by Kraig Labs and Kings Group. The deal combines Kraig Labs’ industry leading fibers with Kings Group’s business skills and regional enterprise expertise, creating what they believe will be a strong vertical integration for both companies.

Kraig Biocraft Laboratories headquartered in Michigan and Kings Group headquartered in Singapore, believe that the material will not only be applied to apparel. The joint venture is also exploring uses to enhance other industries such as building construction and medical industries.

Source: kraiglabs.com

TSG Finishing completes conversion of its DEFEND solution to plant-based technology

TSG Finishing LLC announced that 100% of its DEFEND brand of water and stain repellent finishes now utilize plant-based technology.

Through the efforts of TSG’s technical and development teams, DEFEND will continue to excel in repelling both water and oil-based products while being “plant-based.” Utilizing and perfecting these applications, TSG can report this technology reduces the amount of PFAS (fluorinated chemical), also known as C6, by one third with the new formulation. Employing a USDA certified bio-based product has been key in the progression of the plant-based formulation.

Brian Rosenstein, CEO of TSG Finishing said, “Phase one was launched in September of last year. We knew that Phase two would take a bit longer due to it being a one-sided spray process instead of straight immersion system. Hats off to our technical team for getting the job done ahead of schedule. It is refreshing to be able to say that 100% of our DEFEND offerings now include USDA-certified plant-based technology.”

TSG Finishing has over 120 years of textile finishing expertise.

Source: tsgfinishing.com

NCTO applauds Biden administration’s executive orders to solidify US PPE supply chains

National Council of Textile Organizations (NCTO) president and CEO Kim Glas has issued statements supporting President Joe Biden’s recent executive orders aimed at solidifying U.S. supply chains for personal protective equipment (PPE) and medical supplies, as well as actions outlined in the administration’s “National Strategy for the COVID-19 Response and Pandemic Preparedness.”

“We commend President Biden for taking action in his first days in office to strengthen our domestic supply chain and manufacturing base with a ‘Made in America’ executive order directing the federal government to spend taxpayer dollars on American-made goods produced by American workers using American-made components,” said Glas.

Increasing the domestic procurement threshold and the price preferences for domestic goods under the current “Buy American” law will bolster domestic production and stimulate more investment in U.S. manufacturing, said Glas.

“We believe it is critical that taxpayer dollars are used to invest in American manufacturing and our workforce,” said Glas. “It is essential that we close loopholes in our Buy America laws, expand application and product coverage of domestic content rules, and close unnecessary contract waivers that undermine American manufacturing and its workforce.”

Glas also thanked Senator Sherrod Brown (D-OH) and Representative Kathy Manning (D-NC) for their leadership in sending a recent letter to President Biden, requesting the president prioritize “Made in America” personal protective equipment (PPE) purchases and outlining key steps the administration can take to produce and procure quality American-made PPE for frontline workers.

In addition, NCTO issued a statement welcoming President Biden’s action plan and COVID-19 response, accompanied by a series of executive orders, including an orderto strengthen U.S. supply chains by directing federal agencies to use the Defense Production Act (DPA) to address shortages of PPE and related vaccine supplies.

“We are closely reviewing President Biden’s national strategic plan to confront the pandemic and welcome the executive order signed today to strengthen our supply chains by directing all federal agencies to use the Defense Production Act to address shortages of personal protective equipment, vaccine supplies and essential products,” said Glas. “These are important steps that will help ramp up critical manufacturing of these essential PPE products and other critically needed supplies like tests and vaccines.”

American manufacturers have been at the forefront of the effort to build a domestic PPE supply chain since the onset of the COVID-19 pandemic. The U.S. textile industry retooled production and operations virtually overnight, producing millions of face masks, isolation gowns, testing swabs and other critical medical textiles.

Since its inception, the DPA has been utilized by the Department of Defense to make critical investments in domestic textile manufacturing infrastructure and capacity, creating private-public partnerships through the government’s capital investments under the DPA and guaranteeing purchases through long-term contracts.

“We applaud President Biden’s action today and anticipate further steps including a reported order that will seek to strengthen government procurement of U.S. products in the coming days,” said Glas. “We appreciate President Biden outlining in the ‘National Strategy for the COVID-19 Response and Pandemic Preparedness’ a series of actions and steps the administration will undertake to deploy and manufacture the vaccine and other essential products.”

The NCTO has produced a video campaign that outlines steps the Biden administration and Congress must take to re-shore the production of PPE and the entire supply chain for critical products:

To read the Biden administration’s COVID-19 action plan: whitehouse.gov/wp-content/uploads/2021/01/National-Strategy-for-the-COVID-19-Response-and-Pandemic-Preparedness.pdf

To read NCTO’s critical steps that are necessary to strengthen the U.S. supply chain for essential products: ncto.org/ncto-outlines-key-priorities-for-the-incoming-biden-administration-and-congress-to-strengthen-the-u-s-supply-chain-for-essential-products/

Source: ncto.org

AATCC calls for award and leadership nominations

The American Association of Textile Colorists and Chemists (AATCC) is now accepting nominations for recognition of excellence in the textile industry through March 31, 2021. Nomination forms for all awards are available online at www.aatcc.org/about/awards. Anyone may nominate a deserving colleague or themselves for the following awards:

Olney Medal

Established in honor of Louis Atwell Olney, the founder and first president of AATCC, the Olney Medal recognizes outstanding achievement in textile or polymer chemistry or other fields of chemistry of major importance to textile science.

Chapin Award

Senior Individual (Professional) members who have dedicated 20 or more years of continuous service to the Association are eligible for nomination. The award is presented as a beautifully illustrated scroll.

Millson Award for Invention

Awarded every three years, 2021 is your next opportunity to nominate an inventor or inventors who impacted the textile, fiber, polymer, and medical industries. Nominees need not be AATCC members. Group and posthumous nominations are also welcome.

Technical Committee on Research (TCR) Service Award

The award recognizes up to two Senior Individual (Professional) members, with at least five years of continuous membership in AATCC, who have contributed outstanding technical service to the Association through activity in a research committee.

Future Leaders Award

Young professionals in the fields of textiles, apparel, and related material sciences are eligible for recognition as the future leaders of the Association. Nominees must be members of AATCC, 39 years of age or younger, and exhibit leadership skills.

Education Award

This award recognizes those members who have contributed extensively to the educational activities of AATCC.

Faculty Advisor Award

Nominate AATCC Student Chapter Faculty Advisors who actively work to ensure their AATCC student chapters are active and growing.

While most of the AATCC Board of Directors (BOD) will serve 2021-2022, the Materials Interest Group At-Large role will open sooner. Nominations for the BOD may be sent to Diana Wyman (diana@aatcc.org) by March 31. The election will be held this summer and the selections will be announced at the November 2021 annual meeting. For more information about the current Board members and job responsibilities, visit www.aatcc.org/about/bod.

Source: aatcc.org

Andritz to supply spunlace line to Minet of Romania, with focus on wipes market

Andritz has received an order to supply a neXline spunlace eXcelle line to Minet S.A, based in Ramnicu Valcéa, Romania, for processing various fibers from 25 to 70 gsm to produce a wide range of hygiene products. Start-up is expected during the second quarter of 2022.

The production capacity of the line, which will be the first of its kind in Romania, will be 10,000 tons a year, while the operating speed will be up to 250 m/min and the maximum output at the carding outlet around 1,500 kg/h.

Andritz will deliver a complete line, from web forming to drying. The line will integrate one high-speed TT card, the robust Jetlace Essentiel hydroentanglement unit equipped with a neXecodry S1 system for energy saving, and a neXdry double-drum through-air dryer.

Cristian Niculae, commercial director at Minet, explains: “The Minet group is a company with a long-term vision and sustainable growth. Our strategy has always been to identify and fully meet market needs. The main reason why we decided in favor of a spunlace process was the fast development of our local wipes market recently. Romania should have spunlace nonwovens, so Minet – as the local frontrunner in nonwovens – has decided to become the first factory there using this technology.”

Just recently, Andritz successfully completed the commissioning of a neXline needlepunch eXcelle line for Minet. This line is dedicated to the production of automotive products made from a large variety of fibers. For this contract, Andritz delivered a complete line from fiber preparation to end-of-line, also integrating card, crosslapper, batt drafter, two needlelooms and a Zeta felt drafter with a working width of more than 6 m. The line is also equipped with the unique ProDyn web profiling system, operating as a closed-loop control system in order to ensure perfect evenness of the products.

Founded in 1983, Minet is the most important producer of nonwovens in Romania and serves more than 1,000 customers. The company delivers about 20 million sqm of needlepunched felts per year and offers products with the highest quality standard and which are used in many different fields, such as automotive, geotextiles, and wadding.

Source: andritz.com

ITMA 2023 to focus on technological evolution in textile manufacturing; virtual launch announced

The world’s largest textile and garment technology showcase, ITMA, will continue to present and share innovative manufacturing technology and materials with the industry at its 19th edition in Milan. ITMA 2023 will feature the theme “Transforming the World of Textiles.” It is supported by four sub-themes: advanced materials, automation and digital future, innovative technologies, and sustainability and circularity.

Mr, Ernesto Maurer, president of CEMATEX, the European Committee of Textile Machinery Manufacturers, which owns the ITMA exhibition, elaborated: “ITMA 2023 will highlight innovations and new approaches that serve as catalysts to inspire and help textile and garment manufacturers grow their business, scale and sustain their transformation journey.

“We are in the midst of the 4th Industrial Revolution that is filled with business and technological advances, hence, transformation is even more critical for the continued success of the textile and garment industry. Speed and agility are also of the essence to effectively tackle the ecological and medical challenges that we face today.”

ITMA 2023 will be held from 8 to 14 June at Fiera Milano Rho, Milan. Space application will open on 3 March 2021. A virtual launch for ITMA 2023 will be presented on 28 January at https://www.youtube.com/watch?v=onvS4e9t8xM.

The last ITMA exhibition, held in Barcelona in 2019, featured exhibits from the entire textile and garment making value-chain, including raw materials and fabrics. It drew a record-breaking participation of 1,717 exhibitors from 45 countries and visitorship of almost 105,000 from 136 countries.

Source: itma.com

Bear Fiber introduces American-made Hemp-based socks as part of ‘Hemp Makes It Better’ campaign

Bear Fiber has been promoting hemp fiber for fashion since the 1990s, when they were also helping develop the organic cotton market. The company’s goal now is to help grow the American hemp fiber industry by developing a commercially sustainable market to support farmers, processors, yarn spinners, textile manufacturers and the apparel industry in the United States. To this end, Bear Fiber has produced the first socks made from American hemp.

The socks are part of Bear Fiber’s “Hemp Makes It Better” initiative. They leverage the company’s proprietary methods to produce a soft, stronger, cotton-like hemp fiber, which aim to help reestablish industrial hemp domestically and bring back a “new” natural technical fiber to make better, longer-lasting apparel and wellness products from farm to fashion.

For more than a year, Bear Fiber has been working to develop the perfect hemp/cotton sustainable sock with the expert knitters at the Catawba Valley Community College’s Manufacturing Solutions Center in Conover, NC. They are truly obsessed with making comfortable socks of the highest quality and most sustainable yarns. Hemp is the focus, but their socks also contain a proprietary technology that conforms to feet, will not slouch or droop, do not have that irritating toe seam, breathe naturally and have been blended with organic cotton and REPREVE recycled performance fiber Nylon 6.

Bear Fiber thanks the many Carolina farmers and processors, Catawba Valley Community College’s Manufacturing Solutions Center, Gaston College’s Textile Technology Center, NC State’s Wilson College of Textiles, Fashion For Good, Textile Exchange, Outdoor Retailer, SEAMS, NC Board of Science, Technology or Innovation, and the many others (you know who you are) who have been involved on this journey.

Bear Fiber socks can be pre-ordered at https://www.bearfiber.com/products/bear-fiber-hemp-socks-black.

Source: bearfiber.com

SAYA Rscuw fibers receive ISPO Textrends award

SAYA, a new name in recycled fiber, has been awarded the 2021/22 ISPO Textrends Selection Award in Fibers & Insulations for two offerings, Rscuw and Rscuw Raw, which provide a renewal solution for leftover rolls of fabric and cutting scrap that doesn’t make it into a garment.

Each year the ISPO Awards honor the highlight products of the sports industry which are the result of innovation, passion and creativity. The ISPO Selection Award highlights outstanding products in the category Fibers & Insulations.

The SAYA Rscuw Project (Recycled Scrap and Cutting Waste) addresses the garment industry’s largest areas of hidden waste: cutting scrap and overstock fabrics. Statistically cutting scrap amounts to 25% wastage per yard with fabric overruns amounting to 8.7 million tons in 2019. In addition, fabric overstock recycling has been difficult and expensive. SAYA Rscuw, which is made of a combination of overstock/cutting scrap and post consumer recycled PET bottles, creates new recycling possibilities for what would typically end up in landfills.

“SAYA fibers were developed with the goal of advancing recycled fibers to meet the performance expectations of both consumers and product developers. Today’s consumers are using their purchasing power to demand sustainability, but they don’t want to sacrifice performance. With SAYA Rscuw there is no longer compromise needed and we are making progress in refining the technology needed to renew fabric and eventually garments,” said Jason Hsu, SAYA Sales Manager.

Rscuw Raw is differentiated because the fibers are recycled without the bleaching process, retaining the original source color of offcuts, deadstock and/or tinted PET bottles. Being unbleached, the fiber is up to 30% more energy efficient and carbon friendly compared to bleached renewed fibers.

SAYA Rscuw and Rscuw Raw are available with several performance enhancements, including ChromShield solution-dye technology, to provide ultra-rich color and superior fade resistance, stretch made with 50% Recycled PET + 50% Bio-Based PTT, antibacterial properties and filament sizes ranging from microfiber for ultimate drape to ballistic options for maximum strength and abrasion resistance.

Source: sayarenew.com

World Congress on Textile Coating 2021 to offer all-virtual program

International Newsletters Ltd, the publisher of Technical Textiles International magazine, will offer the first online edition of World Congress on Textile Coating, 11-12 & 18-19 February 2021. The event will feature five sessions over four days with live discussion forums following each session for maximum attendee participation.

“The program aims to be inspiring and informative, and will showcase the best innovations and collaborative actions in the industry. Functionality can be added to textiles and nonwovens at the beginning or the end of the supply chain, with an increasing range of raw materials, offering many options when designing and realizing a high-performance fabric. At the other end, there are many ways, such as applying a coating, to add functionality to an otherwise finished product. For example, the current pandemic has prompted new commercial anti-viral processes and four such presentations will outline the impact on industry and its response to the global pandemic,” says Dr Nick Butler, head of the conference organizing committee.

World Congress on Textile Coating will feature time dedicated to networking, encouraging attendees to interact with conference speakers and industry peers throughout the online program, offering the opportunity to expand professional networks. All the presentations and discussion forums will be recorded for post-event viewing.

Event sponsors imogo AB, Lamberti SpA, JX Nippon ANCI and Weitmann & Konrad GmbH & Co. KG will give individual presentations and host Q&A during the four days of the event.

For the full program, speakers and abstracts: https://www.technical-textiles.online/WCTC.

For press credentials to attend the event: Jill Gwinnutt at jill.gwinnutt@intnews.com.

Source: technical-textiles.net

Heimtextil, Techtextil and Texprocess postponed until 2022

Back in September 2020, a decision was reached by Messe Frankfurt and the industries involved to forgo any physical events in Frankfurt through the first quarter of 2021. Now, following close consultation with customers, it has become necessary to postpone the international physical trade fairs planned for April and May – Heimtextil, Techtextil and Texprocess – as a result of the regulations and travel restrictions that have been imposed in Germany and internationally.

Events are effectively banned in Germany, and ongoing international travel restrictions mean that it is impossible to make any trade fair plans for April or May 2021. “The coronavirus pandemic has taken center-stage, and our plans have not escaped its impact. In light of the current situation, it would not be possible for us to satisfy our customers’ requirements for international trade fairs in April or May,” said Detlef Braun, a member of the Executive Board of Messe Frankfurt.

Due to the fact that physical events are not possible, Messe Frankfurt will be offering digital content offerings for Heimtextil, Techtextil & Texprocess.

Heimtextil will now take place from 11 to 14 January 2022, with Techtextil and Texprocess planned for second quarter of 2022, dates to be announced.

Source: messefrankfurt.com

Shemesh Automation expands US footprint with purchase of new facility in Wisconsin

Shemesh Automation has responded to tremendous growth in its U.S. customer-base with the purchase of a new facility in Green Bay, Wisconsin. The 43,055 square-foot site will be the flagship venue for Shemesh’s new U.S. subsidiary, Shemesh USA Inc. It will house the subsidiary’s complete spare parts inventory, a 200ppm complete wet wipes packaging demonstration line, including rotary liquid filling, conduction sealing, rolls stuffing and labelling machines, as well as serve as the new headquarters for Shemesh USA, Inc.

Shemesh USA Inc’s Director of North American Operations, Mark Calliari, said, “When businesses grow as rapidly as Shemesh has in North America in recent years, it can be easy to forget the values that underpinned that growth. Not so at Shemesh. The investment in our impressive Green Bay facility, the full inventory of parts, demonstration line, and of course the growing team are all indicative of our commitment to driving excellence and supporting our customers on their journey. When you buy Shemesh, you are not just buying top-of-the-line machinery, you are buying into a long-term partnership – our significant investment in U.S.-based personnel and now our Green Bay facility is testament to that. I am incredibly excited to be a part of this exciting new chapter for Shemesh and look forward to supporting our growth and that of our customers in the territory.”

Source: shemeshautomation.com

Hologenix, Kelheim to launch Celliant Viscose infrared fiber at ISPO Munich

Hologenix, creators of Celliant, infrared responsive technology, and Kelheim Fibres, a leading manufacturer of viscose specialty fibers, have partnered to launch Celliant Viscose at ISPO Munich 2021, which is being presented virtually Feb. 1-5. Celliant Viscose is a finalist in Best Products by ISPO and will be showcased in the Fibers & Insulations Category for ISPO Textrends, where realistic views and 3-D simulations will be available for each material.

The introduction of nature-based Celliant Viscose will be the first in-fiber infrared sustainable solution on the market. An alternative to synthetic fibers and extremely versatile, Celliant Viscose blends well with cotton, micromodal, lyocell, and wool varieties (including cashmere). It also has many applications across industries as it is ideal for performance wear, luxury loungewear, casual wear and bedding.

Celliant Viscose features natural, ethically sourced minerals embedded into plant-based fibers to create infrared products that capture and convert body heat into infrared, increasing local circulation and improved cellular oxygenation. This results in stronger performance, faster recovery and better sleep.

Celliant Viscose provides all the benefits of being a viscose fiber — lightweight, soft, highly breathable, excellent moisture management — as well as fiber enhancements from Celliant infrared technology. Celliant’s proprietary blend of natural minerals allows textiles to capture and convert body heat into full-spectrum infrared energy, resulting in stronger performance, faster recovery and better sleep. In addition, Celliant is durable and will not wash out, lasting the useful life of the product it powers.

As opposed to other IR viscose products which are coatings based, Celliant Viscose’s in-fiber solution increases wearability and longevity with a soft feel, durability from washing and longer life. The combination of Kelheim’s distinctive technology and the Celliant additives creates this unique fiber that provides full functionality without the need for any additional processing step — a new standard in the field of sustainable IR viscose fibers. Hologenix says this single processing also makes Celliant Viscose more cost-effective and time-efficient than coatings

Celliant is rigorously tested by a Science Advisory Board composed of experts in the fields of physics, biology, chemistry and medicine. The Science Advisory Board has overseen 10 clinical, technical and physical trials, and seven published studies that demonstrate Celliant’s effectiveness and the benefits of infrared energy.

Source: celliant.com/celliant-viscose/

Messe Frankfurt India to present hybrid edition of Techtextil India in 2021

The new hybrid edition of Techtextil India poised to be held from 1 – 3 September 2021 at Hall 4, Bombay Exhibition Centre, Mumbai. The combination of physical and digital platforms will enable exhibitors to connect with wider audiences, increase their market presence and expand their business alliances significantly.

While the physical fair offers the benefit of face-to-face interaction under strict observance of safety protocols, the digital platform will help exhibitors increase their brand exposure and interact with potential buyers from across the globe via features such as live streaming, video calls, live chats and more. Live product demonstration on dual platforms will further enable exhibitors to showcase their products and new emerging technologies to a vast array of business attendees.

The hybrid fair will also make collaborative engagements extremely simple through its AI assisted platform. Potential suppliers will be automatically matched when buyers launch product or service queries, following which virtual appointments can be set-up at a mutually agreed upon time.

Currently the Indian technical textile industry is pegged at USD 19 billion (growing at a CAGR of 12% since the past five years) and accounts to approximately 13% of India’s total textile and apparel market*. With new demands arising in the segment, the hybrid edition of Techtextil India 2021 will enable technical textile players to engage with businesses beyond geographical constraints, forge new alliances and gain specialised insights to strategically equip themselves for the new normal.

Source: in.messefrankfurt.com

Nonwovens Institute introduces new virtual spunbond and meltblown course

Professionals in the nonwovens/engineered fabrics industry are invited to advance their technical skills in a new 2-day nonwoven short course in the “Virtual Introduction to Spunbond and Meltblown Technology.” This course was developed by North Carolina State University’s Nonwovens Institute and launched by INDA, the Association of Nonwoven Fabrics Industry. The all-virtual course is designed to help manufacturers meet the demand for comprehensive training in the spunbond and meltblown web forming processes used to manufacture respirator/medical face masks, wipes, absorbent hygiene, filtration media, sorbents, and insulation among other end uses.

The course will be held on consecutive Wednesdays, March 24 and March 31, 2021, for a total of 11.5 hours of rigorous training, and available for a two-week review after the course concludes. Production tours of NWI’s spunbond and meltblown lines led by NWI’s renowned team of industry and nonwoven expert instructors are a key component of the virtual agenda.

Expert Instructors for the new course include:

- Pierre D. Grondin, Product Development Director, Nonwovens Institute NWI

- Bryan Haynes, Ph.D., Director of Research and Engineering in Global Nonwovens, Kimberly-Clark Corporation

- Jeffrey Krueger, Ph.D., Raw Material Technology Leader, Kimberly-Clark Global Nonwovens

- Amy Minton, Physical Testing Lab Manager, The Nonwovens Institute NWI

- David Nelson, Assistant Director, Industry Engagement and Education, NWI, 3M, (retired)

- Behnam Pourdeyhimi, Ph.D., William A. Klopman Distinguished Professor of Textile Materials and Associate Dean for Industry Research and Extension, North Carolina State University, and Executive Director, NWI

To register or for more information, visit: https://www.inda.org/education/advanced-training.php

Source: inda.org

Freudenberg Performance Materials introduces ECO-CHECK sustainability label

Freudenberg Performance Materials announced its ECO-CHECK label to identify particularly sustainable products within its portfolio. The label is designed to help customers quickly and clearly identify sustainable products. Freudenberg products bearing the ECO-CHECK label meet demanding criteria in at least one of four categories: 1) Its manufacture saves resources; 2) It improves the manufacturing footprint of our customers; 3) It is recyclable, biodegradable or can be disposed of in an environmentally friendly manner after use; 4) Certain features contribute to a long service life of the product.

“The ECO-CHECK label quickly and accurately indicates to our customers at a glance that the relevant product offers a significant advantage in terms of environmental protection compared to our standard products or those of our competitors,” explained John McNabb, CTO for Freudenberg Performance Materials.

Many of Freudenberg’s products bearing the ECO-CHECK label contain a high proportion of recycled polyethylene terephthalate (PET), derived for example from plastic bottles. In this case, the most important environmental advantage is the reduction in CO2 emissions. Typical examples of products offering this benefit are carpet backings and components for shoes and clothing, including Freudenberg’s comfortemp materials.

Increased durability, raw material savings and improved eco-efficiency for customers are the main features of numerous Freudenberg’s Evolon fabrics, which are used by consumers in the form of bed linen, bath towels and reusable cleaning cloths, for example.

The ECO-CHECK label also demonstrates the significant sustainability advantage of a small number of manufacturing and processing steps for a particular healthcare product: a hydrophilic PU foam with a direct coating of silicone adhesives, which is used in modern wound care.

For more information about ECO-CHECK: http://www.freudenberg-pm.com/eco-check.

Source: freudenberg-pm.com

Spinnova joins Zero Discharge of Hazardous Chemicals’ ‘Roadmap to Zero’ initiative

Spinnova, a startup focused on environmentally friendly fiber solutions for the apparel industry, announced it has become a contributor of the Zero Discharge of Hazardous Chemicals’ “Roadmap to Zero” programme. ZDHC’s objective is to protect the planet by reducing the textile industry’s chemical footprint.

ZDHC is a group of apparel and footwear brands and retailers working together to lead the industry towards zero discharge of hazardous chemicals. ZDHC enables a cleaner industry of the future by, for example, finding safer alternatives and managing the Manufacturing Restricted Substances List. The MRSL supports good chemical management by helping avoid the use of banned substances during production and manufacturing.

Spinnova’s breakthrough technology represents the cleanest fiber alternative in the industry, according to the company. Spinova’s fiber production method is not a regenerative one, but instead the wood or waste based raw material is mechanically refined and dry spun into filament. Fiber produced this way produces no side or waste streams, including zero waste water.

As Spinnova approaches commercial production phase and develops yarn and fabric, it is also developing sustainable finishing treatments that will commit to the MRSL. Spinnova has partnered with leading brands such as Bergans of Norway, Bestseller and Marimekko.

Source: spinnova.com

Kelheim Fibres achieves EMAS certification for corporate environmental performance

Kelheim Fibres GmbH has become the first viscose fiber manufacturer worldwide to receive EMAS (Eco Management and Audit Scheme) certification.

EMAS is an eco-management certification system developed by the European Union. EMAS includes the globally applicable ISO 14001 standard and goes beyond its requirements by demanding more transparency and continuous improvement. Certified companies report in their annual EMAS Environmental Statement on their environmental goals and their progress in meeting them. During the audit preceding the certification, the independent environmental auditor thoroughly investigated all departments of the company, from the production itself to the company canteen. He found no non-conformances and was impressed by the competence and the high sense of responsibility among Kelheim’s employees, according to the company.

In contrast to the EU Ecolabel and similar certifications, EMAS does not apply to individual products or services, but certifies the complete environmental performance of the company. This benefits not only the protection.

“Our aspiration is that our fibers offer an eco-friendly and high-performance alternative to synthetic materials,” said Craig Barker, CEO at Kelheim Fibres. “So, it’s not enough that our fibers are made from renewable resources and that they are fully biodegradable – our environmental awareness must include the whole production process and all that goes with it if we want to safeguard our credibility. The EMAS certification proves that we take this responsibility seriously.”

Source: kelheim-fibres.com

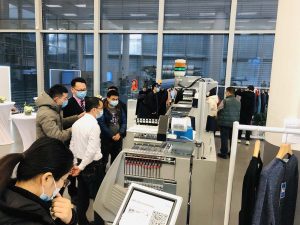

KARL MAYER hosts event in Changzhou, China, to present STOLL flat-knitting innovations

KARL MAYER hosted its first presentation of the STOLL brand during a three-day in-house product show at the KARL MAYER facility in Changzhou, China. As the COVID-19 infection rate in China is at a level that enables face-to-face meeting, the event attracted 380 visitors from 170 companies. Most of them traveled to KARL MAYER (CHINA) in Changzhou from the greater Shanghai area, and a few others came from the north of China.

The event showcased STOLL flat knitting machine business and highlighted KARL MAYER’s roadmap for this product line going forward. The STOLL brand will continue to operate independently as part of KARL MAYER with the same contacts, but with the support of the group of companies. An exclusive selection of the innovations in the flat knitting sector was on show in Changzhou. Customers and prospects who attended the event were reportedly impressed with the

Source: karlmayer.com

AATCC Foundation joins Centennial Celebration

January 2021 begins a year-long celebration commemorating the American Association Of Textile Chemists and Colorists (AATCC) 100th Anniversary. As part of its recognition of this milestone, AATCC is calling for contributions in honor or in memory of someone who influenced education and careers in textiles. The first 100 individuals who contribute $100 or more to the AATCC Foundation in 2021 receive a commemorative pin.

AATCC Foundation Inc. was created as the charitable arm of the association. The AATCC Foundation’s mission is to:

- promote and support the science and knowledge of textile design, coloration, materials, processing, and testing;

- promote continued education and provide educational assistance; and

- communicate research findings to the general public.

The foundation accomplishes this mission through its textile undergraduate and graduate scholarships and its student research support grants program.

To donate to the AATCC Foundation: www.aatcc.org/foundation/

INDA submits PPE policy recommendations to U.S. Department of Commerce

The U.S. Department of Commerce’s Bureau of Industry and Security issued a call for input regarding the condition of the Public Health Industrial Base (PHIB) and to offer recommendations about ways to ensure that essential medicines, medical countermeasures and critical inputs are made in the United States. INDA, Association of the Nonwoven Fabrics Industry, which represents member companies who supply finished products identified by the government as being critical to the PHIB, submitted a series of recommendations.

INDA’s members participate in the supply chain for various personal protective equipment (PPE) and other device medical countermeasures, including:

• disposable surgical apparel including surgical dress, caps, hoods, suits, shoe covers;

• non-surgical isolation and patient gowns;

• surgical gowns;

• wound dressings;

• non-surgical isolation gowns;

• pediatric/child face masks;

• surgical masks;

• and surgical respirators.

Meltblown nonwoven material, specifically the fine fiber electrostatically charged grade of meltblown, has been of particular interest during the COVID-19 crisis. According to INDA, prior to 2020 (i.e., pre-COVID-19), more than 80% of U.S. demand for medical and surgical facemasks (N95 Respirators, N95 Masks, ASTM Level 1,2,3 Masks) was supplied by China and Taiwan. When the COVID-19 crisis took hold, both entities blocked exports of these items to meet their own national demands, and the U.S. was left scrambling for these materials for healthcare workers just as healthcare workers were getting inundated with infected patients.

To protect against such a scenario in the future, INDA’s recommendations call on U.S. Congress and the incoming Biden Administration to adopt and implement the following principles through legislation, Executive Order, or other appropriate means:

- Maintain strong domestic procurement rules for federal PPE purchases substantially similar to the Berry Amendment and the Kissell Amendment. Taxpayer dollars should not go to China and other offshore PPE producers only to have those same producers withhold access to vital supplies and equipment when of global shortages arise. Federal government domestic purchasing requirements for PPE will create the stable demand for U.S.-made PPE that will incentivize investment and production in domestic PPE manufacturing. Federal procurement rules should also work to ensure that contracts utilize U.S. manufacturing capacity before non-U.S. PPE can be purchased under a domestic non-availability determination.

- Support capital investment in domestic PPE and medical supply production by creating long-term contract requirements for federal purchases of these items. A strong consistent demand signal for U.S.-made PPE and medical supplies is absolutely critical for companies making capital investments in domestic PPE and medical supply production. Long-term contract requirements for federal purchases of a minimum of three years would ensure that American manufacturers would recoup investments into manufacturing facilities and equipment and provide stability in the supply chain.

- Implement forward-looking policies to shore up the Strategic National Stockpile and to identify, incentivize, and maintain a robust domestic supply chain for PPE and medical supplies. Our Strategic National Stockpile (SNS) must be better prepared to answer our needs efficiently and adequately during a pandemic or other public health emergency. This will require additional advance planning by the executive branch and proper oversight by Congress. The SNS must also conduct critical domestic supply chain mapping to identify gaps in the supply chain and develop recommendations to meet existing and future supply chain needs.

- Create federal incentives for private sector purchases of domestically produced PPE. Expanding the domestic customer base for PPE beyond the federal government and to the private sector will provide long term stability to U.S. PPE suppliers and enhance our national manufacturing capacity.

- Provide funding assistance for companies to reconstitute domestic PPE supply chains. The federal government should provide grants to companies that took the initiative to repurpose their factories and purchase equipment in order to rapidly increase domestic production of critical PPE items amid the COVID-19 crisis. Further support mechanisms such as additional grants and/or special tax credits for companies that make future investments in domestic PPE production should also be provided.

Source: inda.org

* International Fiber Journal is owned by INDA, Association of the Nonwoven Fabrics Industry (inda.org).

Glatfelter to acquire Georgia-Pacific’s US nonwovens business for $175M

Glatfelter Corporation, a global supplier of engineered materials, announced the signing of a definitive agreement to purchase Georgia-Pacific’s U.S. nonwovens business for $175 million, subject to customary post-closing purchase price adjustments.

Under terms of the deal, Glatfelter will acquire Georgia-Pacific’s Mount Holly, North Carolina, airlaid manufacturing business and an R&D pilot line for nonwovens product development in Memphis, Tennessee, which collectively employ approximately 150 people. The Mount Holly facility has a capacity of 37,000 metric tons and produces high-quality airlaid products focused on wipes and tabletop materials. The R&D pilot line and additional technical resources will enhance ongoing innovation efforts.

“The agreement to acquire Georgia-Pacific’s U.S. nonwovens business further reinforces our commitment to invest in growth opportunities as part of Glatfelter’s ongoing transformation while also expanding our operating footprint in the United States,” said Dante C. Parrini, Chairman and Chief Executive Officer of Glatfelter. “Our airlaid business has delivered strong results throughout an unprecedented 2020. The Mount Holly facility, along with the R&D pilot line, will allow us to continue to build on this success and better serve our customers.”

Georgia-Pacific’s U.S. nonwovens business generates annual net sales and adjusted EBITDA of approximately $100 million and $20 million, respectively. Glatfelter expects to realize annual cost synergies of approximately $4 million to $6 million within three years and incur one-time costs of approximately $10 million for transaction fees and integration.

Glatfelter plans to finance the acquisition through a combination of cash on hand and borrowing under its existing revolving credit facility.

The transaction is subject to customary closing conditions, including receipt of required regulatory clearances. Credit Suisse acted as Glatfelter’s financial advisor in connection with the transaction, and Shearman & Sterling LLP as its legal advisor.

Source: glatfelter.com

Royal DSM, Clariter partner to develop fiber-based chemical recycling technology

Royal DSM, a global science-based company in Nutrition, Health and Sustainable Living, and Clariter, an international clean-tech company, announced a strategic partnership to pursue a next-generation chemical recycling solution for products based on DSM’s Dyneema, an ultra-high-molecular-weight polyethylene (UHMWPE) fiber. As a first step, sample products – including ropes, nets, and ballistic materials made with Dyneema – were successfully converted at Clariter’s pilot plant in Poland, demonstrating the recyclability potential of Dyneema and underlining the active commitment of DSM Protective Materials to shape a more sustainable world.

In line with its ambitious sustainability targets, and following the successful launch of bio-based Dyneema (mass balance), DSM Protective Materials is actively pursuing reuse and recycling solutions for end-of-life Dyneema-based products. To drive technical recycling solutions, DSM Protective Materials and Clariter partnered to test the feasibility of using Dyneema as a feedstock in Clariter’s chemical recycling process. Sample products made with Dyneema were used in Clariter’s tests at its pilot plant in Poland. The positive results confirm the technical viability of transforming Dyneema®-based end-products into high-value, industrial grade, product families: oils, waxes, and solvents via Clariter’s patented 3-step chemical recycling process. These can be further used as ingredients to manufacture new end- and consumer products.

Moving forward, DSM Protective Materials and Clariter will continue to drive this initiative to shape a more sustainable world. Specifically, building on the success of the lab-scale trial, Clariter has scheduled commercial-scale trials at its facility in South Africa for 2021, with the aim to use Dyneema-derived feedstock in its full-scale European plants that will be built in the coming years. In addition, DSM will continue to actively explore the possibilities of reducing the environmental impact of Dyneema across all product life stages.

Source: dsm.com | clariter.com

Ascend Performance Materials acquires Eurostar Engineering Plastics

Ascend Performance Materials has purchased Eurostar Engineering Plastics, a France-based compounder with a broad portfolio of flame-retardant engineered plastics and expertise in halogen-free formulations.

“Eurostar’s experience in compounded polyamides fits well within our own portfolio and manufacturing capabilities,” said John Saunders, Ascend’s vice president for Europe. “Their Starflam materials are enabling the transitions to clean energy and transportation, and smarter devices.”

Last year, Ascend acquired the Italian firms Poliblend and Esseti Plast, as well as a compounding facility in China.

“We are following through on our strategy of becoming a more global, diversified and reliable supplier to our customers,” said Phil McDivitt, Ascend’s president and CEO. “While the past 10 months have been challenging, we have remained focused on providing our customers with the solutions and support they need to continue growing.”

Ascend, the world’s largest fully integrated producer of polyamide 66 resin, gains a full portfolio of UL yellow card certified flame-retardant, as well as water contact and thermally conductive, engineered plastics with the purchase. The company has said these materials will play an integral role in e-mobility, as well as in smart appliances, industrial automation and consumer electronics.

Terms of the transaction were not disclosed.

Source: ascendmaterials.com

MMI Textiles announces new appointments, promotions heading into 2021

MMI Textiles Inc., a global diversified supplier of industrial and custom fabrics and textile components with military, tactical, medical, commercial and apparel expertise, has announced one new executive hire, Kathleen Stevens as Chief Financial Officer and four promotions, including Debbie Grant to Chief of Staff, Nick Rivera to Chief Operating Officer, Geoffrey Senko to Director of Business Development and Joshua Slack to Supply Chain Manager.

Prior to joining MMI Textiles as Chief Financial Officer (CFO), Kathleen Stevens served as the CFO of Standby Screw Machine Products, as well as the CFO of Ohio Association of Polygraph Examiners. She brings more than 35 years of financial, treasury and accounting experience to the position, and an exemplary record for building teams and growing multi-million dollar global companies. Stevens is a graduate of Baldwin-Wallace University.

Nick Rivera, MMI Textiles’ longest tenured employee, brings nearly 15 years of experience in customer service, production and operations to his new position as Chief Operating Officer (COO). Under Rivera’s guidance as Director of Operations since 2014, MMI has experienced consistent, double digit growth and expansion across multiple markets. In his new role as COO, he will continue to be responsible for contributing to the company’s growth and expansion through oversight of day-to-day administrative and operational functions of the company. Rivera is a graduate of Cleveland State University.

Debbie Grant, as Chief of Staff (CoS), will build on her 11-year tenure with MMI Textiles, where she oversees marketing, customer service, human resources, office systems/IT, professional certifications, and works on strategic projects. She brings more than 30 years of corporate experience to the position, including roles with JCPenney, American Greetings and Cole Managed Vision. Grant is a graduate of The Ohio State University.

Geoffrey Senko has been with MMI for over 10 years as a sales representative and successive positions as regional sales manager and national accounts manager. In his new position as Director of Business Development, Senko will develop and implement plans designed to build customer relationships and capture new opportunities on a global scale. Senko is a soon to be graduate of Cleveland State University.

As the new Supply Chain Manager, Joshua Slack will build on his five years’ experience with MMI in customer service and production. In his new position, he will oversee and manage the company’s logistics strategy and operations with a focus on process efficiency and productivity. He will also be responsible for continuing to develop and maintain vendor and distributor relationships. Slack is a graduate of Lorain County Community College.

Source: mmitextiles.com

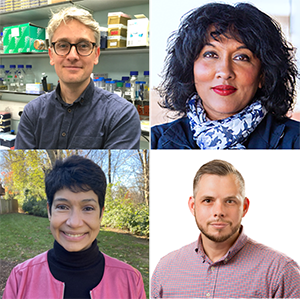

Ascend announces medical advisory board for Acteev

Comprising internationally recognized experts in the fields of PPE evaluation, viral pathology, epidemiology and infectious diseases, the board will provide scientific review and advice on end applications of Acteev technology, including masks, filtration, fabrics and engineered plastics. Acteev technology combines virus-deactivating active zinc ions with the softness of polyamide fabrics and fibers to deliver unparalleled performance and antimicrobial efficacy. Acteev’s patent-pending technology embeds active zinc ions into the matrix of the polymer. Unlike topical finishes or coatings, the zinc ions don’t flake away, providing long-lasting functionality.

“This medical advisory board brings together some of the most distinguished researchers and medical experts from around the world,” said Dr. Vikram Gopal, Ascend’s senior vice president and chief technology officer. “We launched Acteev as a novel way to help fight the spread of the COVID-19 pandemic, and this team of advisors will be invaluable as we seek to rapidly develop Acteev to its full potential.”

C. Raina MacIntyre, MBBS Hons 1, FRACP, FAFPHM, M App Epid, Ph.D., is a professor of biosecurity at the University of New South Wales and head of the Global Biosecurity program at the Kirby Institute for Infection and Immunity. She is Director of Australia’s NHMRC Centre for Research Excellence in Integrated Systems for Epidemic Response. She earned her medical degree from the University of Sydney and Ph.D. in epidemiology from The Australian National University.

Karoll Cortez, M.D., M.H.S., is an infectious disease physician at Greater Baltimore Medical Center. Previously she served as Medical Officer in the Infectious Control Devices branch of the Center for Devices and Radiological Health for the U.S. Food and Drug Administration and as a physician scientist at the National Cancer Institute and the National Institute of Allergy and Infectious Disease at the National Institute of Health. Dr. Cortez received her medical degree from the Universidad Central de Venezuela and master’s from the Duke University School of Medicine.

Christopher McDevitt, Ph.D. is an Australian Research Council Future Fellow and principal investigator in the Chemical Biology of Bacterial Pathogens Laboratory at the University of Melbourne, Department of Microbiology and Immunology. He completed six years of postdoctoral research at the University of Oxford after earning his Ph.D. from the University of Queensland, Australia.

Aartjan te Velthuis, Ph.D., is an assistant professor at Princeton University, Department of Molecular Biology. Previously, he was a Wellcome Trust Henry Dale Fellow and group leader at the University of Cambridge, Department of Pathology. He did his postdoctoral training at the Sir William Dunn School of Pathology at the University of Oxford. Dr. te Velthuis received a Ph.D. in molecular virology from Leiden University in the Netherlands.

Source: ascendmaterials.com