In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant to our industry from manmade to natural to bio-based fibers, innovations in nonwoven, woven, braided and technical textiles, technologies for additives, bonding, coatings and polymers, and applications from apparel to hygiene to transportation, and more. Here we will post news stories relevant to textile fibers and their downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg at ken@ifj.com.

Most recent update: December 20, 2023

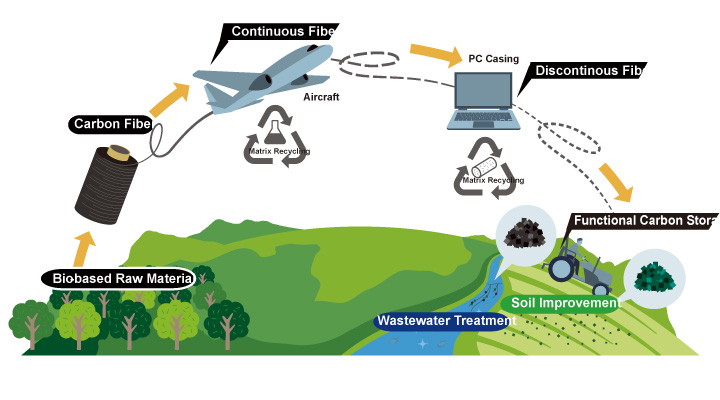

Toray Breakthrough: Recycled Carbon Fiber From Boeing 787

Toray Industries, Inc. announced the successful development of recycled carbon fiber (rCF) derived from the production process of Boeing 787 components, using Toray’s advanced carbon fiber, TORAYCATM.

The rCF, based on pyrolysis recycling, has been integrated into the Lenovo ThinkPad X1 Carbon Gen 12 as reinforcement filler for thermoplastic pellets. Toray and Lenovo will continue collaborating to expand rCF usage in other Lenovo products.

The rCF initiative aligns with Boeing and Lenovo’s commitment to minimizing environmental impact. Boeing aims to reduce solid waste going to landfill and produce recyclable materials, while Lenovo focuses on reducing the carbon footprint of its products. Toray’s rCF repurposes high-performance carbon fiber from Boeing’s aircraft production into Lenovo’s ultra-light laptop PC.

Lenovo’s Yasumichi Tsukamoto, Executive Director and Distinguished Engineer, Commercial Product Solutions Development, expressed commitment to sustainable practices, making a positive social and environmental impact through the integration of recycled carbon fiber into the ThinkPad X1 Carbon.

Boeing emphasized its collaboration with universities and industry to advance technology for recovering carbon fiber from composite materials, diverting it from landfills and creating a market for high-value recycled material like laptop casings.

Panda Biotech to Open One Hemp Fiber Separation Facilities in Texas

Panda Biotech in Dallas, Texas, announced that it’s ready to bring its huge Panda High Plains Hemp Gin online and begin production early 2024, calling the Wichita Falls facility the largest decortication center in the western hemisphere and one of the largest in the world.

The company said building construction of the 500,000-square-foot facility is complete, and the official commissioning process to bring the gin online has begun.

Panda said the Hemp Gin will process 10 metric tons of industrial hemp per hour to produce textile-grade fiber, hurd, short-fiber hurd mix, and a nutrient-rich co-product that will be pelletized.

According to Panda Biotech, industrial hemp has thousands of uses, from textiles and paper to building materials and cat litter.

Hemp decortication means the bast fibers and hurd fibers are separated in a process done via a decortication machine that mechanically separates the fibers of the hemp plant.

Panda Biotech said it has also partnered with Oritain, a scientific traceability company, to bring the most traceable hemp grown 100% in the U.S. to market.

The company said it’s “actively signing contracts” with producers to grow the hemp feedstock for the 2024 growing season, as well as buying hemp fiber that has already been harvested or processed.

Davis-Standard Announces Agreement to Acquire Extrusion Technology Group

Davis-Standard, LLC, a global leader in the extrusion equipment and services sector, announced that it had reached a definitive agreement to acquire the Extrusion Technology Group (“ETG”) from entities controlled by the Dutch Investor Nimbus. The acquisition is subject to customary closing conditions. Davis-Standard has been majority owned by funds affiliated with Gamut Capital Management, L.P. (“Gamut”) since December 2021 and serves the global infrastructure and packaging end-markets with a highly engineered suite of extrusion equipment and converting systems supported by world-class aftermarket spare parts, service, and support for its base of industry critical customers.

ETG is a well-established player in the global extrusion equipment and services sector with a history dating back to 1943. With a reputation for world-class engineering and innovation, ETG is a leader in the supply of extrusion equipment and downstream processing equipment, in addition to extensive tooling, dies, spare parts, and service capabilities, for the global pipe, profile, film and sheet markets. ETG’s operations span Europe, the United States, and Asia and includes long-established and storied brands, such as Battenfeld-Cincinnati, Exelliq (formerly known as Greiner Extrusion), and Simplas.

Giovanni Spitale, CEO of Davis-Standard, stated: “We have long admired ETG’s capabilities and highly engineered products and are thrilled to welcome ETG into the Davis-Standard family of brands. The acquisition of ETG will be highly complementary and diversifying to our fast-growing enterprise, and we believe it will allow Davis-Standard to provide a broader and deeper product portfolio to our customers. We intend to establish the ETG business as a standalone segment that will continue to serve its base of customers with additional support and capabilities from the broader Davis-Standard platform. We believe that the combination of our world-class engineering capabilities, our global scale, and the sharing of best practices will only enhance our ever-expanding value proposition in the extrusion value chain.”

Gerold Schley, CEO of ETG, will join the Davis-Standard senior leadership team and continue to manage the ETG business after closing of the transaction. “I am exceptionally proud of the growth and success that we have achieved across all of ETG’s businesses under the stewardship of Nimbus. This merger is a great outcome that we believe will create a best-in-class, diversified global supplier of highly engineered extrusion equipment.”

Fi-Tech Launches New Website

Fi-Tech, Inc. announced the launch of its newly designed website, www.fi-tech.com. The website features a fresh, modern look with updated informative content to help visitors understand its complete line of machinery and products for the synthetic fiber, nonwoven fabric, textile, converting and tobacco industries.

Key features of the new website include:

- Secure Connection

- Improved Brand Recognition for Partners

- Optimized Search Structure

- Simplified User-Friendly Navigation

“We are pleased to unveil our new website to our customers, partners, and the industries we serve. With updated information and photography, this site will enhance the online experience for our valued customers and partners,” said Jeffrey Bassett, managing director. “The site’s new, secure and modern design reflects our dedication to serving our customers and partners.”

Fi-Tech, Inc., with offices in Richmond, Va., and San Luis Potosi, Mexico, is the leading manufacturers’ representative and distribution company in North America serving the synthetic fiber, nonwoven fabric, textile, converting and tobacco industries.

The World of Wipes® (WOW) International Conference Calls for Presentations

INDA’s World of Wipes® (WOW) International Conference is accepting abstracts on wipes products, markets, and technologies to be presented in Minneapolis, MN, June 17-20, 2024. The deadline for abstract submissions is January 12, 2024.

Experts in dry and wet nonwoven wipes, sustainability, end-use markets, substrate formation, raw materials and fibers, liquid ingredients, packaging, machinery, and market trends and data are encouraged to submit a brief abstract. The abstracts may be submitted via the WOW website.

Topics for consideration include:

- Dry and wet wipes

- Circular economy

- Sustainability / End-of-life implications

- Substrate formation

- Skin care formulations

- Raw materials

- Packaging

- Machinery and equipment

- Market trends and consumer insight

- Regulations

- Ecommerce / Retail channels

Presenting at WOW is an opportunity to be recognized for your innovation, connect with senior-level leaders, gain potential partners and customers, and change the future of wipes.

Ginni Filaments to Divest Textile Unit to RSWM

The board of Ginni Filaments Ltd., an Indian company specializing in traditional and technical textiles, has approved the divestment of its spinning, knitting, and processing unit to RSWM Limited, another prominent textile player in India. The sale is expected to be completed in three months.

Ginni Filaments is engaged in the manufacturing of traditional textiles comprising of yarn, fabric and garments and technical textiles comprising of nonwovens and consumer products. RSWM is one of the largest and well-established manufacturers of textile products. It is positioned to infuse capital and strengthen its position in this segment. The employees of the various units of Ginni will be secure and have future growth prospects, the company said in a media release.

Mehmet Dasdemir Joins Nonwovens Institute

The Nonwovens Institute (NWI) announced that Mehmet Dasdemir, Ph.D., has been appointed to the position of Director of Product Development for the Institute, succeeding Pierre Grondin who retired from NWI earlier this year after 30 years of service to the nonwovens industry.

In this new role, Dr. Dasdemir is leading the management of NWI’s sponsored product development projects portfolio. He is focused on working with NWI’s industry partners on the development of new nonwoven products and applications, including scale-up using NWI’s extensive pilot facilities. This is an area where NWI brings high value to the nonwovens industry – i.e., in providing an environment where early-stage product designs can benefit from the Institute’s decades of nonwovens application knowledge, along with in-house fabrication and testing capability, to enable proof-of-concept in an extremely cost-effective manner. He is also serving as an internal and external advocate for products developed at NWI.

Eastman Completes Sale of Texas City Operations

Eastman Chemical Company announced that it has completed the previously reported sale of its Texas City Operations to INEOS Acetyls.

Texas City Operations was previously part of Eastman’s Chemical Intermediates segment. Eastman retains ownership of its plasticizer business at the site, which INEOS now operates for Eastman as part of this agreement. Eastman will also continue to manufacture acetyls at its Tennessee Operations in Kingsport.

The total sale price of $490 million consists of approximately $415 million cash at closing and the remainder in equal installments on the first and second anniversaries of the closing. The final purchase price is subject to working capital and other customary post-closing adjustments. Proceeds from the divestiture in the near term are expected to be used for debt repayment.

Erik Ripple Appointed New President, CEO at NatureWorks

NatureWorks, a leading manufacturer of polylactic acid (PLA) biopolymers made from renewable resources, announced the appointment of Erik Ripple as the company’s new president and chief executive officer.

Ripple will succeed interim President and CEO Jill Zullo, who has served in the role since March 2023 when former CEO, Rich Altice, retired from NatureWorks.

Ripple comes to NatureWorks from Nexeon, Ltd. in the United Kingdom, a manufacturer of silicon carbide composites for electric vehicle batteries. As chief strategy officer, he led the commercial, engineering and program teams enabling the launch of their first commercial product to battery manufacturers.

Natureworks_logo.png

Prior to that position, Ripple was the chief growth and innovation officer with Ingevity. In this role, he successfully positioned Ingevity to accelerate their latent innovation efforts and designed several acquisition pathways for Ingevity to execute. Ripple was previously the President of Asia Pacific, and the Senior Vice President for Performance Materials (PM) while living in Shanghai, China.

Before joining Ingevity in 2010, Ripple spent 18 years with Eastman Chemical Company, where he served in leadership roles in innovation, business management and corporate development including holding regional responsibilities in Europe.

Ripple received a Bachelor of Science degree in chemistry from the University of Tennessee and a Master of Business Administration degree from Washington University.

New Dates for INDEX 26

The organizers of INDEX 26 have changed the dates of the event from the April 21-24, 2026, to May 19-22, 2026. The event will be held at Palexpo in Geneva, Switzerland. The event is co-organized by EDANA and Palexpo.

“Although we do not underestimate the effect this diary alteration may have on the planning and logistics of our exhibitors and visitors, we felt it would enable attendees to maximize their presence at both events,” the organizers said in a joint statement. “INDEX™26 will remain full of valuable insights into this dynamic market for which the event is renowned: the much-appreciated free product presentations, seminars & workshops and industry get-togethers will naturally form part of the rich program.”

Additionally, the event will feature a panoply of new experiences in and around the event, many focused on inspiring future generations of nonwovens talent, with the objective of enhancing competitivity and deepening knowledge of new market opportunities.

ITMA ASIA + CITME Concluded with 100,000 Visitors

ITMA ASIA + CITME concluded successfully on 23 November 2023 at the National Exhibition and Convention Centre (NECC) in Shanghai. The five-day combined exhibition featured an exciting showcase of textile machinery from the entire manufacturing value chain. It attracted the strong participation of textile professionals eager to explore the latest automation and sustainable technologies.

The eighth combined exhibition welcomed visitorship of 100,000 from 105 countries and regions. Local Chinese visitors from 31 provinces and cities formed the largest group of visitors, followed by India, Taiwan, South Korea, Bangladesh and Iran.

Visitors from outside mainland China accounted for more than 13 per cent of the visitors. There was a significantly higher number of overseas delegations, including more than a dozen large buyer groups, compared with previous editions.

Exhibitors at ITMA ASIA + CITME 2022 were impressed by the turnout. Georg Stausberg, CEO of the Polymer Processing Solutions Division and Chief Sustainability Officer of the Oerlikon Group, said: “We can look back on a successful show where we were able to meet many of our customers, not only from China, but also from Pakistan, India and Indonesia.”

More than 1,500 exhibitors from 23 countries and regions took part in the exhibition which grossed over 160,000 square meters. Many local and international brand names staged product launches which were well received by visitors.

Rieter Opens Repair Services in Uzbekistan

Rieter announced the opening of its first Repair Services station in Tashkent, Uzbekistan, on December 1. As the country’s most advanced service station, it will enable both faster repair turnaround and minimum production downtime. This will make local customers even more competitive and forms part of Rieter’s growth strategy in this highly attractive focus market.

The new Repair Services station in Tashkent complements Rieter’s strong presence in Uzbekistan, providing state-of-the-art repairs and sustainable solutions combined with dedicated support to local customers. The station’s capabilities cover both mechanical and electronic repairs for all types of Rieter machines, including spinning and winding. In addition, the repair station has a warehouse where critical parts, such as control units, sensors and drives are stocked to ensure quick turnaround times for repairs. The new service station will operate in collaboration with Textile Service Solutions.

Rieter’s global Repair Services network comprises 25 repair stations in 19 countries, strategically located at the doorstep of Rieter customers. Each repair station is fully equipped with the testing and calibration equipment required to provide the highest quality repairs. Certified Rieter repair services engineers perform both on-site and in-workshop repairs, using original Rieter repair components and spare parts.

INDA Releases Upgraded International Nonwovens Directory

INDA, the Association of the Nonwoven Fabrics Industry, has released an upgraded, more user-friendly version of their International Nonwovens Directory. With enhanced search and navigation features, nonwoven professionals can easily source suppliers or manufacturers based on their product needs.

Some of the search categories include:

- Raw material suppliers

- Nonwoven material suppliers

- Machinery and equipment suppliers

- Converters

- Brand owners and marketers

- Service providers

Tony Fragnito, INDA President, said, “INDA is proud to provide this valuable resource to INDA Members and the nonwovens industry. With these upgrades this directory will be the ‘must have’ resource for product developers, R&D, and business development professionals.”

As an added member benefit, INDA Members’ listings will receive priority in Directory search results as well as display an INDA Member badge for all active INDA member companies.

The International Nonwovens Directory is a publicly accessible resource using the following link: INDA Directory.

Innovation Award “Cellulose Fibre Innovation of the Year 2024”

For the fourth time, nova-Institute will award the “Cellulose Fibre Innovation of the Year” at the “Cellulose Fibres Conference 2024” (13-14 March 2024). The conference advisory board will nominate six remarkable products and the nominees have the opportunity to present their innovation to a broad expert audience on the first day of the conference. After voting for the winner, the award ceremony will take place in the evening.

Cellulose fibers show a steadily expanding range of applications. At the same time, markets are driven by technological developments and political framework conditions, especially bans and restrictions on plastics and increasing sustainability requirements for textiles. The European Commission has made the thorough transition towards sustainability and circularity for different industries and especially the textile sector a main focus. All nominees will therefore introduce innovative pathways towards more sustainable technologies and products.

Producers and inventors of innovative technologies and applications are invited to submit a completed application form and a leaflet or a two-page PDF about the product in English by December 15, 2023. A jury will nominate the top six submissions by mid January 2024, and the winner will be chosen at the conference in March.