In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant to our industry from manmade to natural to bio-based fibers, innovations in nonwoven, woven, braided and technical textiles, technologies for additives, bonding, coatings and polymers, and applications from apparel to hygiene to transportation, and more. Here we will post news stories relevant to textile fibers and their downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg at ken@ifj.com.

Most recent update: August 26, 2024

Thomas Olsen to Leave Suominen

Thomas Olsen, EVP Americas, will leave Suominen to pursue new opportunities outside the company. Mr. Markku Koivisto has been appointed as interim EVP, Americas in addition to his current role as EVP, EMEA and CTO. The change is effective as of August 26, 2024.

The process to recruit a new EVP, Americas will be started immediately.

Kimberly-Clark Factory to Close in North Wales

Around 300 jobs will be lost at Kimberly-Clark’s wet-wipe factory in Wales, UK after the company announced it will be closing next year. KC said the closing will take place in 2025 and is a result of the UK governments ban of sale of wet wipes containing plastics from mid 2026. KC said phasing out plastics from baby wipes is part of their sustainability plan, but it wasn’t possible to adapt the manufacturing process in Flint, North Wales in time, and the factory was therefore not viable.

UNIFI® Launches Globally Available Circular Polyester Products Made From Textile Waste

UNIFI, Inc., a leading innovator in recycled and synthetic yarn, announced the launch of two new products, making its circular REPREVE® offering the largest portfolio of regenerated performance polyester in the world. Powered by the Company’s proprietary Textile Takeback™ process, UNIFI® now offers white-dyeable filament yarn and a revolutionary insulation material, ThermaLoop™, representing a major leap forward in scalable textile-to-textile recycling.

“Polyester is the most widely utilized fiber on the planet, and it’s time for transformative change,” said Eddie Ingle, Chief Executive Officer of UNIFI, Inc. “Textile brands can now create solutions with the entire product life cycle in mind and work towards achieving their 2030 environmentally preferred materials targets. Our goal is to provide the best-in-class sustainable products that eliminate the need for virgin materials and reduce carbon emissions.”

Made from 100%* recycled polyester feedstock, with at least 50% textile waste, the two new products both achieve virgin-quality standards. The Textile Takeback™ process recycles both global post-industrial and post-consumer textile waste into next-generation materials using proprietary technologies. Further enhancing value throughout the supply chain, UNIFI will also partner with global brands to take back their waste and keep materials in circulation longer.

With widespread versatility across industries, applications, and colorways, the new circular REPREVE filament yarn is a white, dyeable, high-performance polyester that is designed for the most critical applications. The circular REPREVE polyester line, which also includes black filament yarn and black and white staple fiber, contains the inherent FiberPrint® tracer technology, meaning that all products can gain U-Trust® certification.

ThermaLoop™ insulation, available in down-like fiber, fiberball, and padding, offers performance, recovery, and thermal efficiency. The padding is engineered with REPREVE low melt fiber, a pioneering innovation that enables the production of 100%* recycled synthetic padding. Driven by UNIFI’s ‘waste nothing’ philosophy, ThermaLoop’s launch in black insulation showcases the wide variety of textile waste that can be utilized as feedstock.

The two new products are both available globally now, and can be integrated seamlessly into existing supply chains, without disruption. This commercial scalability tackles a key challenge for polyester-reliant industries, particularly fashion brands, which have long sought to create circular apparel to meet sustainability goals. These products underpin UNIFI’s goal to recycle 1.5 billion T-shirts’ worth of textile waste by fiscal year 2030.

INDA Brings Nonwovens to the 2024 NCSL Legislative Summit

INDA, The Association of the Nonwoven Fabrics Industry recently attended the 2024 NCSL Legislative Summit hosted in Louisville, Kentucky early August. Wes Fisher, Director of Government Affairs, and Sean Grossnickle, Government Affairs Specialist, engaged with hundreds of state legislators and their staff, international delegates, and summit attendees in INDA’s booth. Attendees were eager to learn more about flushability, the California Collection Study, the ins and outs of the nonwovens industry, and, among other policies, state legislation on wipes. This year marked the first time in recent years that INDA has exhibited at the event.

“Securing a booth for INDA during the 2024 NCSL Legislative Summit provided numerous opportunities to speak directly with state legislators and policy stakeholders on wipes labeling and other issues prevalent in the nonwovens industry today,” said Wes Fisher. “The high-level conversations and product demonstrations we had were instrumental in highlighting the crucial role of nonwoven fabrics in consumer households and industrial applications.”

The annual NCSL Legislative Summit hosts one of the nation’s largest and most influential gathering of state legislators, staff, corporations, government agencies, and trade associations. State and national media publications cover the event, disseminating news and stories across the country.

Chinese Nonwoven Output Surges 11%

According to China National Bureau of Statistics, nonwovens output of the Chinese nonwovens companies with sales volumes above 20 million yuan ($2.8 million) achieved a year-on-year increase of 11.4% in the first half of 2024, compared with same period in 2023. Revenue and total profit of these companies rose by 6.4% and 24.7% respectively. But operating profit margin was only 2.5%.

Survey and statistics of China Nonwovens & Industrial Textiles Association (CNITA) shows the capacity utilization of the Chinese spunbond and spunlace nonwovens companies was about 70% in the first half of 2024, higher than the level of the first half of 2023. Many spunbond and spunlace companies responded to the association that prices of their general products have declined to the edge of break-even point.

Source: Web

Lenzing AG Makes Changes to Management Board

The Lenzing Group, a leading supplier of regenerated cellulose fibers for the textile and nonwovens industries, will be making changes to the Management Board. Effective September 1., 2024, Rohit Aggarwal will join the Management Board as CEO. Stephan Sielaff, outgoing CEO of the company, will leave Lenzing at the end of August 2024 by mutual agreement with the Supervisory Board.

Incoming CEO Rohit Aggarwal is a strategic business economist and global leader in the industry, has several decades of experience in leading positions in the textile and chemical industry. Rohit Aggarwal has a sound understanding of the strategic development of international markets and the establishment of efficient management teams through global management positions in Europe, the USA and Asia. Thanks to his broad experience in the global textile, nonwoven and fiber markets, he is well versed with Lenzing’s core business in all its facets, both in terms of content and geography.

Said Lenzing Supervisory Board Chairman Cord Prinzhorn: “This summer, we have managed a highly professional and smooth transition from Stephan Sielaff to his successor. I would like to thank Stephan for his achievements in paving a path of strong improvements during a period of multiple challenges for the company. With Rohit Aggarwal, we have found the right person to manage the ambitious tasks that still lie ahead.”

Hygienix™ 2024 Will Highlight Advancements in Sustainability

INDA, the Association of the Nonwoven Fabrics Industry, announced the conference program for Hygienix™ 2024, November 18-21, The Renaissance Nashville Hotel, Nashville, TN. This year’s theme, “Driving Absorbent Hygiene Product Innovation: Consumer Desires, Market Dynamics & Sustainability Solutions,” will provide insights into the latest industry advancements. The full program is now available on the Hygienix website.

Event highlights include:

Pre-conference webinars

- “Non-PFAS Hydrophobic Technology for Polypropylene Nonwovens”

- “Harnessing AI to Enhance Transparency and Trust in Brand Sustainability”

Workshops (Monday, November 18th)

- “Fundamentals of Absorption Systems and Opportunities in Adult Incontinence”

- “Innovations in Menstrual Care”

- “Baby and Infant Care Market Dynamics”

Networking opportunities

Lunch Arounds with founders of successful hygiene start-ups

Lightning Talks – supercharged elevator pitches

Tabletop Exhibits of leading-edge absorbent hygiene suppliers

Receptions – three extended networking events

Presentation Preview

- Absorbent Hygiene Insights, LLC, “Exploring the Performance of Polyaspartic Acid Superabsorbents in Hygiene Products”

- China National Household Paper Industry Association (CNHPIA), “Latest Development of Disposable Hygiene Products Industry in China”

- Glatfelter Industries (France) SAS, “Capitalizing on Capabilities to Support the Shifting Hygiene Industry”

- Gottlieb Binder GmbH & Co. KG, “Synergy of Components – Upstream Advancements Offering Downstream Sustainability Opportunities”

- Handas Consulting, “The Intersection of Nonwovens, Sustainability and the Environment: An African Perspective”

- INDA, “UN Plastics Treaty Update”

- INDA, “Business Not as Usual – The Impact of Reusables on the Absorbent Hygiene Market”

- Curt G. Joa, Inc., “Efficient Material Utilization in Hygienic Incontinence Articles”

- Joii Ltd., “Using Nonwoven Period Care Products and an AI-backed Mobile Application to Diagnose Heavy Menstrual Bleeding”

- Kuraray Europe GmbH, “Connecting Consumer Insights with AHPs: Designing Elastics & Naturality”

- The LYCRA Company, “From Farm to Fiber: Developing Elastane with 70% Renewable Content”

- MyMicrobiome GmbH, “The Menopausal Skin Microbiome – What Do You Need to Know?”

- Price Hanna Consultants LLC, “Shifting Sands in the Global Economy for Absorbent Hygiene Products”

- Principle Business Enterprises, “The High Cost of Adult Incontinence”

- RPK Consulting, “Shifting to Sustainability: Natural Fibers in Diapers and the Rise of Eco Brands”

- Texol S.R.L., “Functional Substrates to Preserve Skin Microbiome”

- SK Leaveo, “Comprehensive Sustainability in Hygiene Products: Exploring Biodegradable Alternatives and Circular Economy”

- SPARK Solutions For Growth, “There’s an App for That! The New World of Incontinence Tech”

- University of Pennsylvania, Division of Urology, “Latest Medical & Surgical Treatment for Incontinence”

- ZymoChem, “The Final Frontier: A Bio-Based Source for Super Absorbents”

Hygienix Innovation Award™

A highlight of the event, the Hygienix Innovation Award™ will feature presentations from three finalists on Tuesday, November 19th. The winner, to be announced on Thursday, November 21st, will be recognized for their innovative contributions to absorbent hygiene products. Nominations are open until September 16th, 2024. Last year’s winner, Sequel Spiral™ Tampon, received FDA clearance in August 2023 and is expected to be widely available in 2024.

Suominen Invests in Capacity in Sustainable Products at its Alicante Site

Suominen will strengthens its capabilities in sustainable products by investing in a new production line to its site in Alicante, Spain. The new production line increases Suominen’s Card-Pulp-Card (CPC) capacity. The investment is made in line with Suominen’s strategy and supports company’s vision to be the frontrunner in sustainability.

“With this investment we respond to the accelerating demand of sustainable nonwovens in Europe. This investment is made to enhances our profitability and competitiveness,” said Tommi Björnman, President & CEO.

Teijin Frontier Expands European Fashion Business with Paris Showroom

Teijin Frontier Limited announced that its European subsidiary, Teijin Frontier Europe GmbH, has opened a new showroom in Paris with the aim of expanding its fashion business in the region. Launched in June 2024, the showroom displays Teijin Frontier’s fabric collection and products, which is centered on environmentally friendly and functional fibers. The collection includes the company’s ECOPETⓇ polyester fiber, made with recycled post-consumer polyethylene terephthalate (PET), and its ultra-soft and smooth SOLOTEXⓇ polytrimethylene terephthalate (PTT) fiber, as well as textiles and other products that use

these fibers.

In addition to showcasing materials and disseminating information, the showroom will display applications in collaboration with Teijin Frontier’s Japanese suppliers and serve as an exhibition venue for their clients’ brands. The exhibits will change seasonally and align to evolving customer needs.

By opening a showroom in the fashion capital of the Western world, Teijin Frontier aims to increase its

presence as a fiber supplier to the French and European markets. Furthermore, by encouraging customers to visit and learn about its products, Teijin Frontier hopes to uncover new needs and trends, which will be used to guide development of new products and solving customer issues.

Technical Textiles on The Rise in India

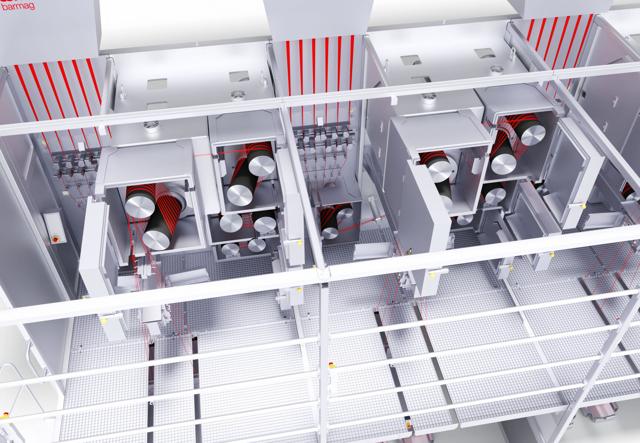

As a traditional textile country, India has also established a strong position in the field of manmade fiber production in recent decades. The West Asian country has now become the second largest polyester yarn manufacturer in the world. The Indian textile industry covers the entire value chain from the melt to the finished textile end product.

The technical textiles sector in particular is regarded as a future market. With an average growth rate of 12% since 2013, this dynamic sector accounts for around 13% of the entire Indian textile and clothing market, according to the government organization Invest India. The market volume has almost doubled in the past ten years. In India, the production of industrial yarn has so far relied heavily on polyamide. Oerlikon Barmag has a strong market position here. “In recent years, we have commissioned plants for numerous customers,” said Dr. Wolfgang Ernst, Head of Sales of the Oerlikon Business Unit Manmade Fibers Solutions.

The construction boom and the increasing use of geotextiles and industrial textiles in various infrastructure projects as well as in agriculture and aquaculture show enormous growth potential. This is supported by the government’s 2021 industrial development program, which includes technical textiles as one of ten priority sectors. The program is based on reducing dependence on imports. Until now, a large proportion of the technical textiles and yarns required in the country have been imported.

Organic Dyes & Pigments acquires Bolger & O’Hearn

Organic Dyes & Pigments LLC recently announced the acquisition of the assets of Bolger & O’Hearn, Inc. located at 27 Slade Street in Fall River, MA effective July 31, 2024. For over 50 years, Bolger & O’Hearn has had a proud history of supplying specialty chemicals and colorants to the textile, paper and coatings industries.

“We are excited to welcome Bolger & O’Hearn and their customers and employees to the ORCO family,” said John D’Amelio, President of ORCO, “this acquisition continues to strengthen ORCO’s presence in key markets and positions us for future growth.”

For Bolger & O’Hearn’s customers, the acquisition will bring greater resources and offerings to back up Bolger’s long-standing commitment to high quality products, services and expertise in solving the market’s toughest specialty chemical and color challenges. As part of the transaction, Bolger’s name will gradually be changed to Organic Dyes and Pigments LLC.

Apex Mills Launches Long-Lasting Stretch Fabric

Apex Mills, a premier USA manufacturer of specialty fabric solutions, announced the launch of OutStretch™, a revolutionary new collection of textiles targeting the high-performance needs of the apparel industry.

Designed for a spandex-free comfortable stretch, OutStretch™ offers exceptional durability and long-lasting quality as a sustainable alternative to fabrics made with elastomer yarns that cannot be recycled.

Exclusively available from Apex Mills, the OutStretch™ fabric collection is a USA-made breakthrough offering exceptional stretch that doesn’t degrade, ensuring superior durability, comfort, moisture-wicking, shape retention and recyclability. Other fabric features include high tensile strength, non-transparency, wrinkle and crease resistance and a soft, supple texture without pilling or “crunchiness” after 25 washings.

The collection has various finishes including fire resistance, antimicrobial/anti-odor protection, abrasion resistance and durable water repellency. It complies with the Berry Amendment, the USMCA Agreement, and the CAFTA-DR Agreement and is OEKO-TEX Standard 100 and ISO9001:2015 certified.

Indorama Ventures Joins the T-REX Project for Textile Recycling

T-REX project

Indorama Ventures Public Company Limited, a global sustainable chemical company, recently announced its role in the groundbreaking T-REX (Textile Recycling Excellence) Project. This ambitious initiative aims to establish a harmonized EU blueprint for the closed-loop sorting and recycling of household textile waste to help the fashion industry transition towards a more circular and sustainable future.

By bringing together key stakeholders across the entire value chain, the project positions itself at the forefront of sustainable innovation.The designated spinning partner, Indorama Ventures, will process the chemical recycled feedstock into polyester yarns and fibers through the extrusion process, ensuring the elimination of impurities. The company’s participation in the project also aligns with its goals of driving the circular economy and circular fashion industry through PET recycling and supply of recycled materials, underscoring its commitment to sustainability.

The T-REX Project launched with the aim of creating a harmonised blueprint which will support the creation of a circular system for post-consumer textile waste within Europe. The EU funded project brings together a consortium of 13 major players from across the entire value chain along with research institutes to transform end-of-use textiles from waste into valuable feedstock and a commodity for new business models that can be adopted at scale.

H&V Releases Comprehensive Line of Solutions Without Using PFAS

As part of its mission to create a cleaner, healthier more sustainable world, Hollingsworth & Vose, a global leader in filtration and energy storage solutions, is introducing PlusZero, a comprehensive line of high-performance solutions manufactured without using per- and polyfluoroalkyl substances, commonly known as PFAS.

The PlusZero line is not only environmentally sound, but it offers high-quality solutions that will help customers meet performance, reliability and affordability goals.

“We have a long tradition of innovation and sustainability at H&V, and PlusZero is our latest breakthrough furthering our commitment to both,” said Mike Clark, H&V’s division president. “After years of research, we have developed a line of zero added PFAS solutions that are not only better for the environment, but smart for business.”

Leveraging H&V’s focus on research and innovation, PlusZero is grounded in the latest technology. The solutions in the PlusZero line have been developed to support the sustainability goals of H&V’s customers by eliminating the use of forever chemicals in the manufacturing procss. At the same time, PlusZero solutions will deliver the same high performance in most applications and largely carry the same price as their legacy counterparts.

Although eliminating the use of PFAS in the manufacture of products is not yet required under regulations, H&V is committed to providing solutions that are sustainable and good for business.