1st Year Ph.D. Student

University of Huddersfield,

United Kingdom.

Subhadeep Paul is pursuing his Ph.D. in Technical Textiles at the Technical Textiles Research Centre, University of Huddersfield. Paul came to Huddersfield after completing his undergraduate and master’s degrees in Textile Engineering and Textile Chemistry, respectively, in India. In his master’s project, Paul developed a multi-functional protective textile that could be used as a UV-resistant, fire retardant and self-cleaning garments.

Paul is currently in his first year at the University of Huddersfield, funded by the Unite Kingdom’s Arts & Humanities Research Council, through the Future Fashion Factory program, a £5.4M collaborative R&D partnership between the University of Huddersfield, University of Leeds, Royal College of Art, and businesses across the UK fashion and textile industries. A key remit of this program is to develop enabling technologies to benefit industry partners by developing new textile technologies, resulting in greater flexibility, added functionality, reduced production cost, and lowering energy use and other environmental impacts.

Research overview

Paul’s studies include an in-depth characterization of wool fibers from different breeds of sheep, both physically and chemically, with a view to relating certain breeds to certain fiber properties. The findings could ultimately be used to develop new products, which are suitable for specific applications. This could open up more applications for the coarser variety of wool fibers available in the UK.

Wool fibers vary between sheep breeds across the world. For example, Australian Merino wool is very different to that from the Lincoln sheep. Wool consists of micro-fibrils in its cortical cells, which define properties like hydrophilicity, strength, fiber length, etc. Parameters such as keratin structure, cystine linkages, helix angle, chemistry of amino acid and its content have not been systematically correlated to sheep breeds in previous studies.

“Wool consists of micro-fibrils in its cortical cells, which define properties like hydrophilicity, strength, fiber length, etc. Parameters such as keratin structure, cystine linkages, helix angle, chemistry of amino acid and its content have not been systematically correlated to sheep breeds in previous studies.”

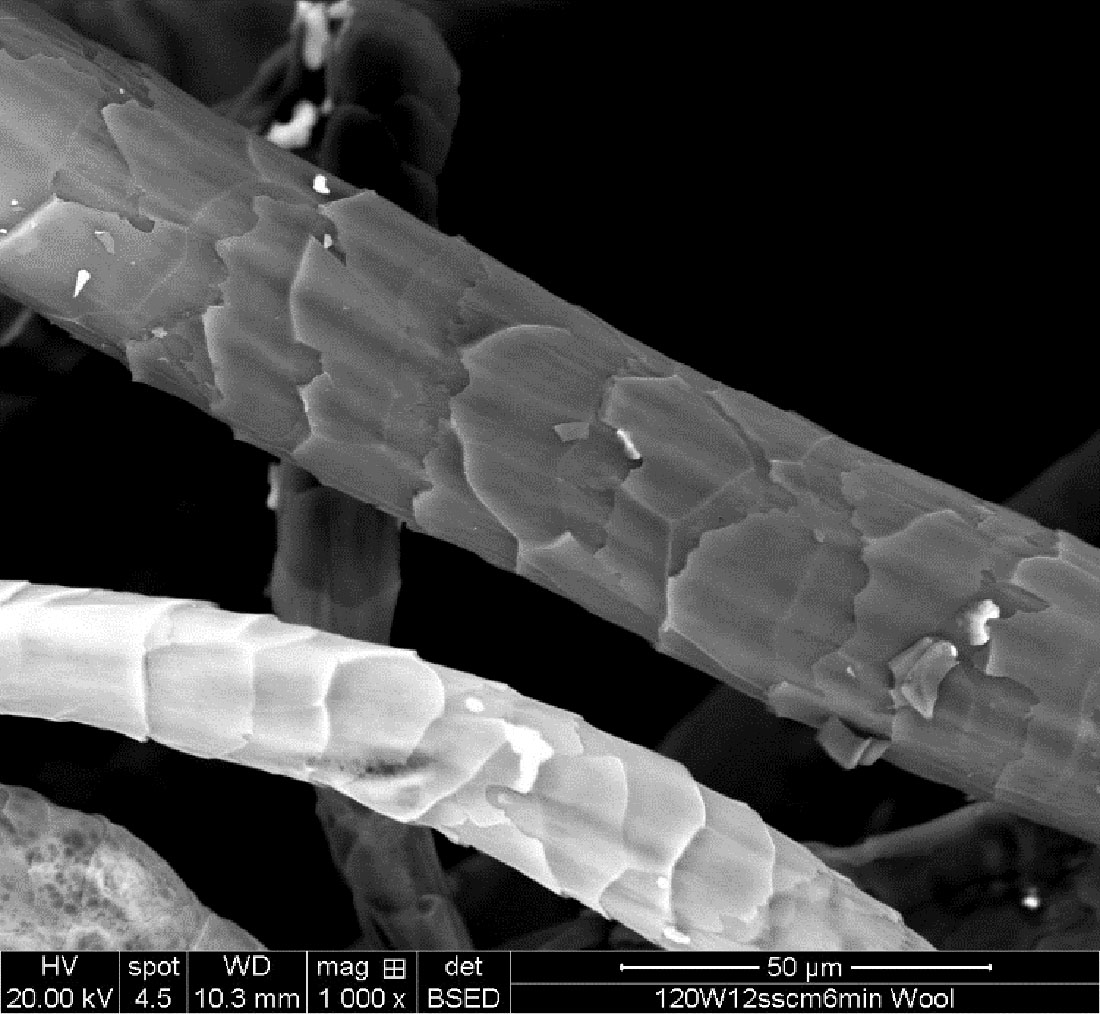

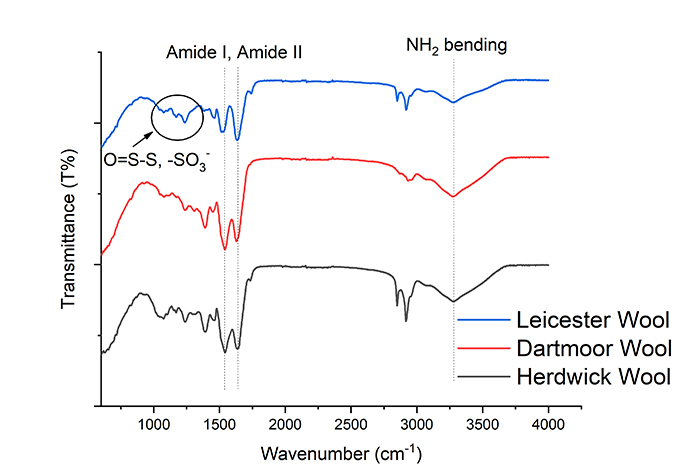

Paul’s work investigates the morphological structure of wool from different breeds to examine the structure of scales and surface properties of the fibers. Wool fibers from all the breeds studied to date have exhibited differences in fiber scale pattern, kemp fiber and surface roughness. FTIR studies revealed the photodegradation phenomenon of different wool breeds and confirmed that wools of various breeds differ in their content of amino acids, linkages that exists between the keratin molecules and the degradation level of the fibers.

Paul will be using this information to develop new textile processing treatments for wool. Wet processing is important to textile production, as it can add value by improving aesthetics, comfort and functional behaviors. However, one of the biggest challenges the textile processing industries face is the consumption of substantial quantities of water and chemicals. A key aim of Paul’s research is to develop a chemically modified fiber using a waterless technology like plasma treatment, which will add beneficial functionality as well as aesthetic value to the textile substrate.

* Fleet Green Farm of Lancashire, England provided the wool samples for the research highlighted in this article.