Many segments of the textile industry rely on adhesives and binders that securely hold a product together, in one way or another. From automotive, medical, hygiene and more, this seemingly invisible technology contributes to the critical success of products that are used by consumers daily. Adhesive and binding solutions are undergoing their own epiphany in the research and development to support the advancement of the products that utilize them, and industry wrestles with sustainability, durability and circularity.

IFJ highlights several companies who share their most recent news in our first edition of the IFJ Adhesives and Binding Roundup.

Michelman’s Unyte® line represents a significant leap forward in technical textile technology. By offering a non-fluorinated range of water-based, environmentally friendly solutions that enhance multiple aspects of textile performance, Michelman enables manufacturers to create more durable, functional, and versatile products. Michelman’s comprehensive portfolio of products provide the ability to improve adhesion, water repellency, and other vital properties, both for synthetic and natural fibers, without relying on fluorinated compounds or substances of concern.

For the medical market, Unyte® 211 binds multiple layers of fabric together, improving durability and wet strength, allowing medical wipes to withstand stringent performance requirements in a medical setting.

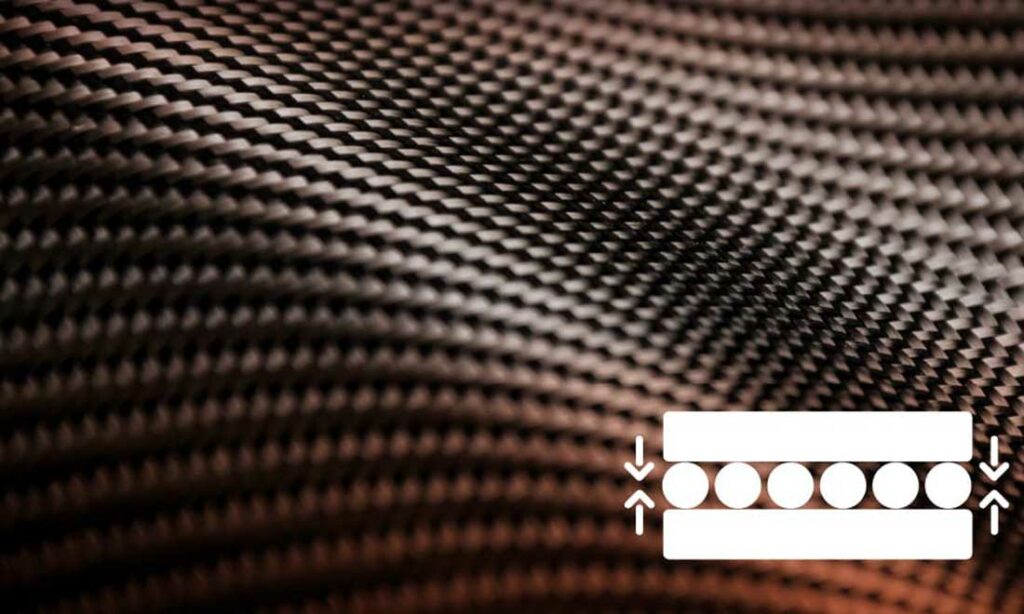

Our next-generation binder for Ultra-High Molecular Weight Polyethylene (UHMWPE) balances bind strength and adhesion between ballistic fabric layers. The binder does not degrade or change performance when exposed to high heat conditions. Beyond binding, the fiber aids in protection against bullets and sharp objects, protecting the wearer.

Polyimide-based Unyte® 620 is used for products that need to withstand high-heat applications. The product is heat stable up to 500ºC and retains the fiber’s adhesion properties. It also offers abrasion resistance.

As more emphasis is put on sustainability, not only do adhesion and bonding agents need to perform – there is a shift to biobased and biodegradable solutions. This aligns well for Michelman, a global developer and manufacturer of environmentally friendly materials across multiple markets. Michelman offers surface additives and polymeric binder solutions for the fibers, technical textiles, composites, coatings, printing, and packaging markets.

Michelman’s expertise extends to a diverse range of applications, including ballistics, synthetics, polymeric and natural fibers, non-woven fabrics, and composites. In these applications, adhesion and binding performance are critical to the success of the specific application and its final use.

Reach Michelman at www.michelman.com.