In June 2019, Lenzing announced plans to establish what will be the largest lyocell cellulosic fiber plant in the world, with an annual capacity of 100,000 tons. To be located in Bangkok, Thailand, it will become operational sometime in 2022.

In addition, the Austrian company has established offices in Sao Paulo, Brazil, with a view to establishing dissolving wood pulp production via a joint venture there. Targeting an annual 450,000 tons of capacity, it will make Lenzing one of the larger scale pulp producers, while at the same time secure its raw material supplies from Brazil.

In normal circumstances these moves would be viewed as extremely ambitious, but as explained in the last issue of International Fiber Journal (Sept/Oct 2019, pages 22-25), the now highly negative public perception of plastics, including synthetic fibers, has seen a clamor for bio-based and natural alternatives, and lyocell certainly ticks all the right boxes.

The push for alternatives is likely to become even more intense as a result of initiatives such as the new Single-Use Plastics Directive, which is being introduced in the European Union.

The California Circular Economy and Plastics Pollution Reduction Act was introduced in June this year and is on its way to adoption. In Canada too, a single-use plastics bill is being drafted along the same lines as the EU Directive.

Development

As Andy Slater, Lenzing’s technical customer services manager explained at the recent Filtech conference held Oct. 22-24, 2019 in Cologne, Germany, the development of lyocell began more than 30 years ago as an alternative to viscose (rayon), with its sustainable credentials very much at the forefront. It is based on a safe and fully enclosed solvent-based process in which 99% of the solvent is recovered, with no by-products or chemistry involved. The fibers are biodegradable and fully compostable and, as such, have a very positive environmental footprint.

Lenzing currently has an existing annual lyocell capacity of 260,000 tons at two plants in Austria and others in the United Kingdom and United States. In addition, it has viscose capacity of over 500,000 tons at plants in China and Indonesia, and a capacity of 575,000 tons of dissolving pulp at sites in Austria and the Czech Republic.

Of the majority of the company’s output, 70% is currently supplied to the apparel industry under the Tencel brand and 30% to the nonwovens sector, branded as Veocel. In addition, the company has a newly-created Industrial Applications operation, which is developing business in specific sectors, such as automotive, denim, filtration, footwear, packaging, protective clothing, and applications in agriculture. All fibers supplied for these specific fields are branded simply as Lenzing.

“We are not looking to diversify, or at mergers and acquisitions, but to grow organically, and [we] have developed specific new tools for this, such as Luxe filaments for high-end apparel and in a similar approach, Web Technology, in which lyocell-based raw materials are being developed for spunmelt nonwovens,” Slater said.

Luxe and Web Technology

The introduction of Luxe in 2017 saw the company enter the filament market for the first time, with filaments offering superior aesthetics, high performance and outstanding comfort for high-end fashion applications.

Lenzing subsequently announced the launch of the €26 million Web Technology platform, targeting nonwovens in 2018, with the commissioning phase for a one-meter wide pilot facility located at the company’s headquarters in Lenzing, Austria.

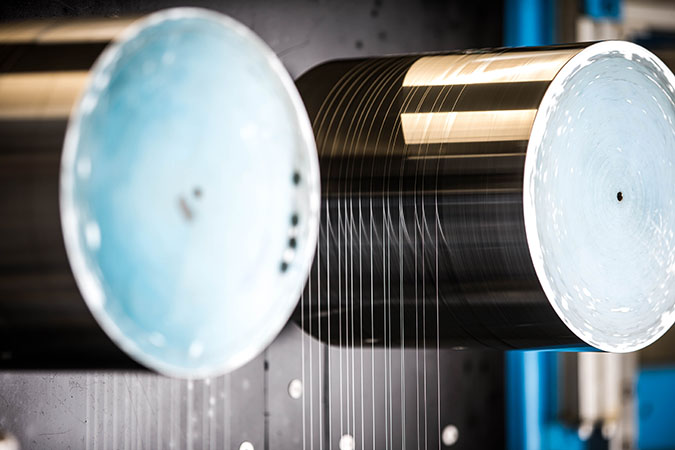

Essentially, the technology involves a nonwoven web formation process that starts with botanic wood pulp and produces a nonwoven fabric made of 100% continuous Lyocell filament. This web can be integrated with standard non-thermal based nonwoven bonding technologies, such as hydroentangling and needlepunching. In addition, the technology uses a self-bonding mechanism where filaments bond into a fabric during the laydown process. This self-bonding mechanism enables a product range with a much wider variety of surface textures, drapability and dimensional stability than other nonwoven technologies utilizing 100% cellulosic fibers.

Lenzing has filed approximately 25 new patents on Web Technology.

Eco Lace

Another new technology is Eco Lace, developed by Lenzing with its nonwoven manufacturing partners for the production of wipes from short-cut Veocel lyocell fibers and pulp, offering some distinct advantages over widely employed synthetic fiber and pulp combinations.

Eco Lace is an extension of the Eco Disperse technique that arose from the demand for flushable wipes.

For flushable wipes, the materials need to be strong enough in the wet state for production and use, but also capable of quickly disintegrating after flushing. In this case, they are also biodegradable, but the combination is not just for flushables. With Eco Lace, it is possible to tune the wet strength of the nonwovens up to 50% by spunlacing at pressures from 65 up 250 bar. As a consequence, their strength can be more than doubled, which is stronger than can be achieved with 60/40 blends of synthetic fibers and pulp.

The absorption is also higher and a low and even stretch can be achieved, with the additional benefit of excellent embossing characteristics in the nonwoven wipes.

Expansions

At its plant in Grimsby, in the U.K., as well as at its plant in Mobile, Alabama, Lenzing is currently carrying out upgrades to its technology and line expansions. These will facilitate a significant increase in the production of short cut fibers, which are produced down to a length of 2mm (so quite different to regular staple fibers), as well as enable the introduction of entirely new fiber grades.

A key attribute of these new fiber grades is their ability to be fibrillated, whether by a wet secondary process or by the end-user via further processing. They are targeted at producers of both wetlaid and airlaid nonwovens, and Slater said current demand for them is outstripping supply, especially in the area of synthetic fibers and plastics replacement.

EU action

The implications of the European Union’s Single-Use Plastics Directive were outlined at another recent conference – EDANA’s Outlook, held in Athens, Greece, from October 9-11.

Richard Knowlson of RPK Consulting, on behalf of Dan-Web North America, explained that its first phase will concentrate on the 10 products most commonly found discarded on European beaches, and the list will be finalized in July 2020. In July 2021, laws will then come into force requiring such products to carry prominent warning labels, with extended producer responsibility for their clean-up, collection and disposal from beaches coming into place in December 2024.

Nonwoven wipes and feminine hygiene products are both on the list of targeted products, although disposable baby diapers will escape action in this first phase.

Raw materials

According to the current definitions of plastics, the following key raw materials are left to work with in order to avoid the EU legislation – wood pulp, viscose, starches, cotton, lyocell, cellulose derivatives, flax/hemp/sisal etc., PHA and proteins.

“Product and process development is at the highest level I can remember, but questions remain, such as if, for example, there is enough viscose and lyocell,” Knowlson said. “The textile industry uses four times more of these fibers and pays more for them, so there will be competition for raw materials and for availability on the existing manufacturing lines that can process them. Everybody should be looking very hard at their supply chain management right now.”

Manufacturers and suppliers in North America will not escape either. The California Circular Economy and Plastics Pollution Reduction Act was introduced in June this year and is on its way to adoption. In Canada too, a single-use plastics bill is being drafted along the same lines as the EU Directive.

All of these measures must be music to the ears of Lenzing’s management board.