The Billion Dollar Collection, launched in June by the H&M Foundation, draws attention to ten sustainable start-ups with the potential to make a positive impact on the fashion industry.

Showcased as garments in a virtual fashion collection, each start-up has a price tag reflecting the estimated support each company believes they need to achieve scale for their disruptive innovations.

“We have worked with innovators for many years now and their biggest hurdle to realizing their ideas is funding and support to build scalable technology solutions,” said Diana Amini, global manager of the H&M Foundation. “They also need collaboration partners like fashion brands and suppliers. With this campaign we want to create awareness of the impact sustainable innovation can achieve if given the opportunity to grow. Together, we can create a shift in the fashion industry where sustainability and innovation are implemented as default practice.”

The non-profit H&M Foundation has supported early-stage innovation since 2015 through the Global Change Award, recognizing ideas that can make the fashion industry circular.

With over 20,000 entries since its inception, this innovation challenge shows start-up companies are ready to transform the fashion industry. More than ever, customers are demanding sustainable fashion while fashion companies are talking about transformation – and yet many start-ups struggle to receive the necessary support to bring their ideas to the scale required to go beyond capsule collections and pilots.

“It’s crucial to support sustainable innovation if fashion is going to make the shift to a more sustainable industry,” adds Karl-Johan Persson, chairman of H&M Group. “The Billion Dollar Collection highlights this untapped opportunity.”

Hurdle

The collection was created in computer-generated imagery by Mackevision, part of Accenture Interactive. Using the latest CGI character design technology, Mackevision created digital avatars from scratch, bringing the textures and details of the collection to life through movement. If the fashion industry and its communities, embraced these 10 disruptive innovations, the collection could become reality and be produced at scale.

Accenture also brought its 360-degree value approach to the collection with the 2030 UN Sustainable Development Goals in mind. The model shows each innovation could have a big, positive impact for the planet, if given the opportunity to scale.

CO2 polyester

Fairbrics, based in Clichy, France, for example, has developed a process for manufacturing polyester from waste CO2, which is estimated to have the potential to achieve an annual net reduction of 720,000 metric tons of carbon dioxide emissions by 2030.

The process captures industrial fumes that would otherwise be released into the air and turns them into polyester and is seeking $6.6 million to scale-up in order to prove industrial feasibility.

This waste is 10 times less expensive than petroleum products and not only reduces CO2 emissions but also uses the emissions as part of the solution. The aim is to introduce the first synthetic fiber with the potential of having a net positive impact on climate change.

CO2 is captured from the waste and reacted with a catalyst and solvent to generate the chemicals that are used for polyester synthesis. The product can then be used in exactly the same way as current petroleum-based molecules, to produce polyester pellets and yarns.’

Fermentation

Various companies are looking at mycelium from mushrooms as the natural raw material for new apparel, including Bolt Threads, Ecovative, Mogu, MycoWorks, and MycoTech.

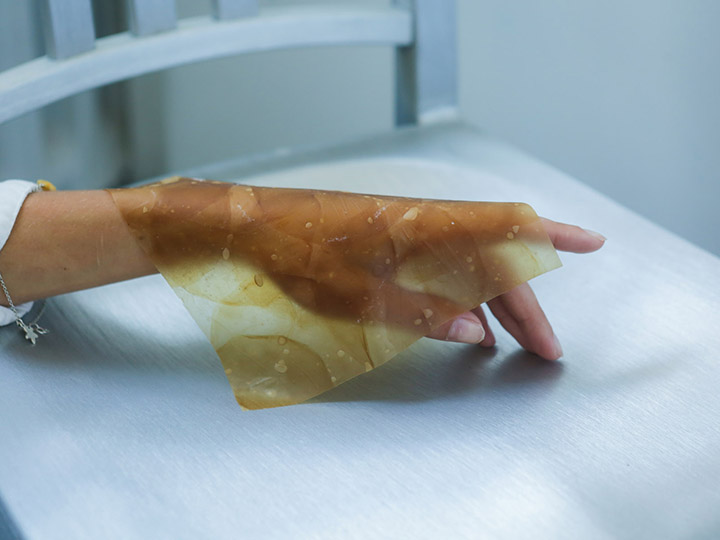

MycoTEX, based in Soest, The Netherlands, however, points out that all of its competitors in this space use a solid-state fermentation process based on agricultural waste that needs to be developed from scratch. By contrast, MycoTEX is taking a biotech approach that uses a liquid fermentation process that has already been proven, making it easier to scale by being sustainably grown in a lab.

MycoTEX can resemble leather and plastic and can replace both materials with a vegan and compostable alternative, made in different thicknesses and textures. The material can also be dope-dyed and will naturally decompose at end-of-life.

The company is taking elements from different industries to allow for a quicker scale-up and a more flexible supply chain; and it is collaborating with a large machine manufacturer to develop a process in which the mycelium is grown in a lab and then robotically applied onto 3D molds.

By combining sustainable biomaterials with seamless production technologies, MycoTEX can offer personalized fashion and is seeking $3 million in new funding.

Wine leftovers

Most synthetic leather on the market has a petrochemical origin, but Vegea, based in Milan, Italy, is turning the leftovers from wine production into a fine leather-like material. Traditionally, the skins, stalks and seeds from the grapes are burnt as waste but Vegea has developed a process of turning them into a valuable resource without the use of any toxic solvents, heavy metals, or substances dangerous for humans or the environment.

The vegan leather can be produced in all finishes, colors, elasticities and thicknesses, according to the company, which aims to raise $600,000 to support the scaling of this business.

Vegea has already had collaborations with large apparel brands including H&M, and Le Coq Sportif, as well as with the luxury car maker Bentley.

Algae

Algaeing, based in Berlin, Germany and seeking $5 million, has patented a new bio-based formulation derived from algae, from which both dyestuffs and fibers can be created.

Algaeing’s dyestuffs utilize various algae species to produce a wide range of appealing colors. The benefits of using an algae bio-source go far beyond the removal of chemically synthesized colorants, and include vastly reduced water consumption, chemical/fertilizer use, and carbon dioxide emissions.

During May this year, the company announced its collaboration with leading spunmelt nonwovens producer Avgol, which is focused on modifying the aesthetic qualities of sustainable polyolefin-based spunbond and meltblown fabrics.

Spray-on membranes

Biodegradable and mineral-based membranes for outdoor wear, which are both waterproof and breathable have been developed by Zürich, Switzerland-based Dimpora, which has placed an $8 million price tag on its development.

Conventional outdoor wear is treated with fluorinated chemicals to ensure waterproof, breathable and dirt-repellent characteristics. Fluorine-free membranes have entered the market, but until now there haven’t been any that effectively ensure both waterproofness and breathability, the company says.

Dimpora Eco Pur and Sane membranes are based on a non-toxic, fluorine-free and biodegradable solutions and in their latest iteration can be painted, sprayed or printed on top of already assembled garments, with the potential to revolutionize outdoor gear manufacturing.

SeaChange

Other start-ups represented in the Billion Dollar Collection focus on new production methods and supply chain process aids.

SeaChange Technologies, of Raleigh, North Carolina, has patented a system that has the potential to significantly reduce the generation of wastewater in the dyeing and finishing of textiles.

It plugs directly into existing factory systems and separates water from toxins in a single step process with the help of a powerful jet turbine. The water is released as clean water vapor into the atmosphere, and the sludge is converted into a concentrated dry powder that can be reused.

Adidas has provided support to SeaChange to develop the technology and run pilot trials in Taiwan, and Fashion for Good has also coordinated trials with it in India for leading brands. The company is seeking $5 million to advance the process.

RFiD Threads

A disruptive new technology that allows a radio-frequency identification (RFID) chip to be invisibly integrated into a garment has been developed by Adetex.ID, based in Nottingham, UK, which is looking for $13.7 million to accelerate its patented RFiD Threads.

RFiD Threads, which have been tested by major fashion brands, remain viable during the entire lifecycle of a garment and can withstand washing or tumble drying at any temperature. They can also be reused.

The multitude of uses they can be put to include providing real-time data on sales and stock, scanning of returns, and validating that a product return is not a counterfeit. Unlike conventional technology, RFiD Threads cannot be damaged, detected or removed by a customer.

Unspun

San Francisco-based Unspun’s patented technology translates a 30-second body scan into perfectly fitting jeans, eliminating the need for inventory and dramatically reduces the waste created by current production methods.

The company’s aim is to reduce global carbon emissions by 1% through automated, localized, and intentional manufacturing and it has developed a 3D-woven garment system it believes will move far beyond traditional cut-and-sew process, to be introduced before the end of 2021. Its price-tag in the collection is $25 million.

Waste flows

Seeing data and the digitalization of waste flows as key to a circular economy, Reverse Resources, based in Tallin, Estonia, has created a platform for mapping, steering and tracing textile leftovers to reduce the need for virgin materials, and needs a hefty $120 million to commercialize.

The company’s Software-as-a-Service (SaaS) platform enables brands and buyers to connect recycling partners with their textile and garment suppliers, give access to and increase quality of waste in collaboration with nominated waste handlers, enabling waste to become the new raw material for the fashion industry.

Kenyan nettles

Green Nettle Textile is seeking a modest $60,000 for a project to turn stinging nettles into linen-like fabrics to provide a livelihood to hundreds of farmers across Kenya.

By working with local farmers, it has established organic stinging nettle plantations on non-productive slopes. Nettles are native to these kinds of areas and a hardy crop, often the only remaining vegetable during an extended dry spell. The plantations give local communities an eco-friendly cash crop while preventing erosion and bridging the growing gap of sustainable textile supply.

Reinvention

“The Billion Dollar Collection presents a unique opportunity to help the fashion industry reinvent itself through sustainable innovations that can fuel future growth and bring positive change,” said Jill Standish, senior managing director and global retail industry group lead at Accenture. “By adopting our 360-degree value approach for this collection, we are demonstrating how these new innovations can deliver value across multiple dimensions including sustainability – and move past narrowly defined views of value.”

“It’s crucial to support sustainable innovation if fashion is going to make the shift to a more sustainable industry,” adds Karl-Johan Persson, chairman of H&M Group. “The Billion Dollar Collection highlights this untapped opportunity.”

For more information, visit billiondollarcollection.com.