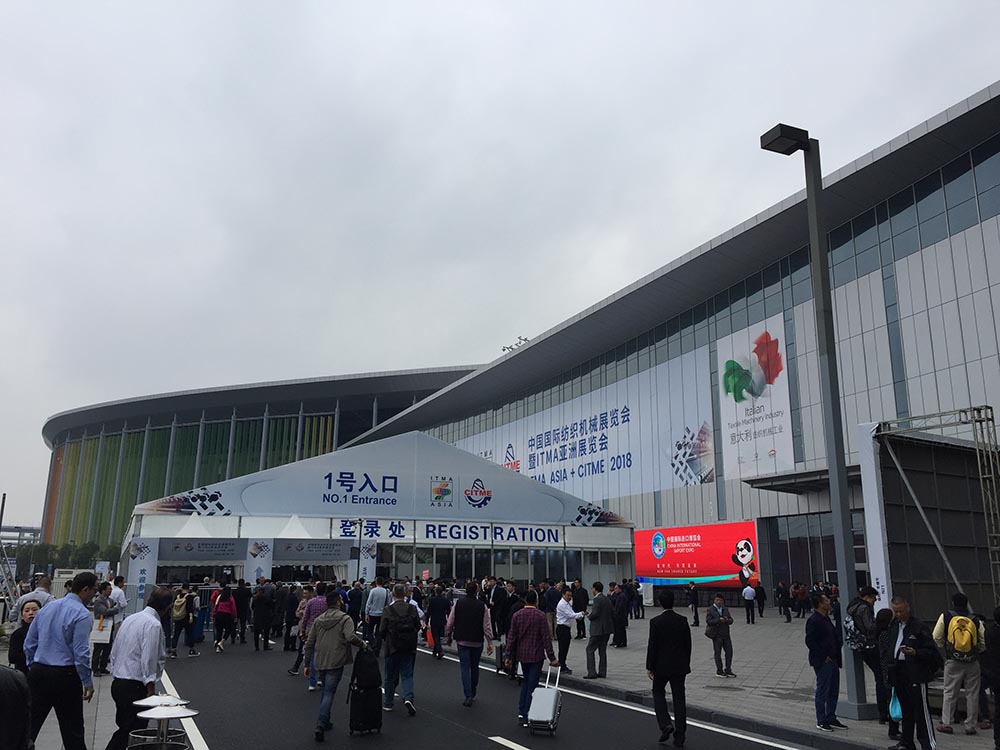

During ITMA ASIA + CITME 2018 held on October 15-19 in Shanghai, China, both the exhibitor numbers and exhibition area both reached record highs, showing the stable growth in the global and Chinese textile, manmade fiber, nonwoven and related machinery industries, even though current global trade conflicts have cast a shadow on these sectors.

This was the second time that ITMA ASIA + CITME was held at the National Exhibition and Convention Center (NECC). The NECC has a total exhibition area of 500,000 m2, including 400,000 m2 of indoor space, which is the world’s second largest area after the 496,000 m2 of the Hannover Exhibition Center in Germany.

Exhibitors

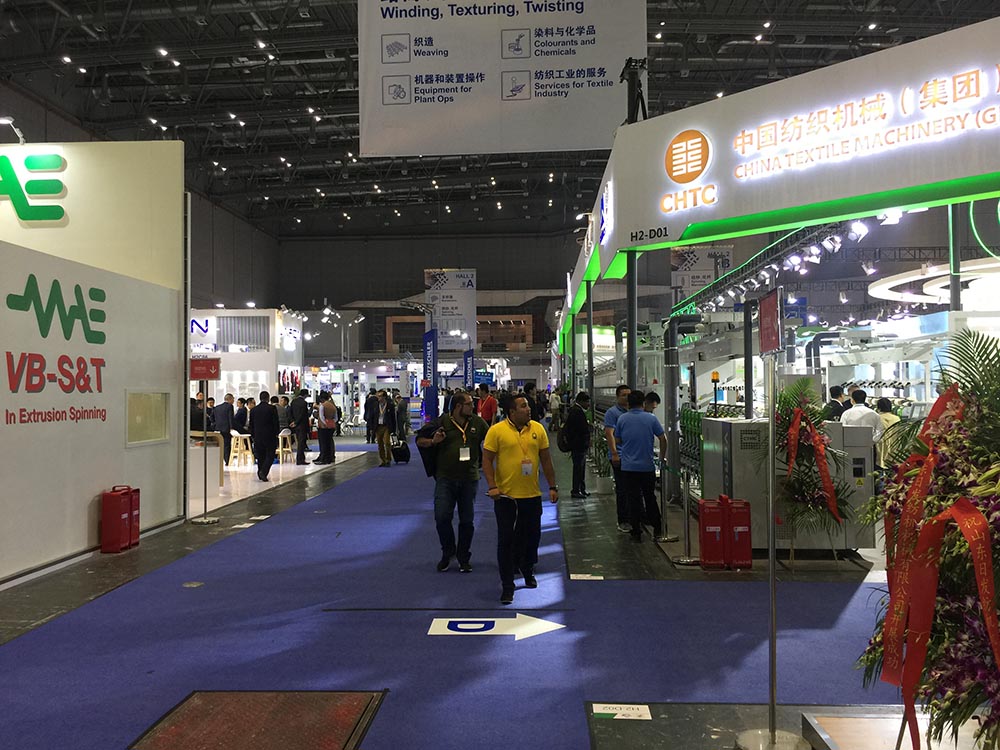

According to the organizers, 1,733 exhibitors from 28 countries attended the event, covering more than 180,000 m2 in seven halls (Hall 1-6 and the North Hall) of the NECC. Over 1,200 exhibitors were from China; the rest (more than 500) were mostly from Germany, Italy, Japan and Switzerland. By comparison, the last exhibition, ITMA ASIA + CITME 2016, had 1,673 exhibitors covering 170,000 m2 in six halls of the NECC.

Manmade fiber and nonwoven machines and technologies were shown in Hall 1, Hall 2 and the North Hall, which included a special area that highlighted the latest research and development and innovations in the sectors of nonwovens, manmade fibers and technical textiles.

The main organizers and sponsors of the exhibition included China Textile Machinery Association (CTMA), Comité Européen des Constructeurs de Machines Textiles (CEMATEX), Sub-Council of Textile Industry, China Council for the Promotion of International Trade (CCPIT TEX), China International Exhibition Center Group Corporation (CIEC), Japan Textile Machinery Association (JTMA), Beijing Textile Machinery International Exhibition and ITMA Services.

The organizers estimated there were more than 100,000 professionals from around 100 countries visiting ITMA ASIA + CITME 2018 over the five days of the event, where manufacturers presented their new products, solutions and strategies for tackling challenges and seizing new opportunities.

Trade conflicts impact

The foundation of global trade has been shaken in the past few years by a series of trade conflicts, especially between the USA and China.

Xu Yingxin, executive vice chairman of CCPIT TEX and vice president of the China National Textile and Apparel Council (CNTAC), the largest national organization for textile and textile machinery in China, said the trade disputes would benefit neither side.

“The China-USA trade conflict will impact mostly on fabric products, but do little damage to the textile machinery industry. It will affect 900 textile items in two major categories, at a trade value of $4.4 billion,” said Xu. These 900-plus items cover all yarn, fabric and technical textile products, as well as some home textile products.

“The trade conflict not only damages the interests of Chinese manufacturers, but also impacts heavily on the US textile industry, for example, US cotton producers. So far as I know, US cotton organizations such as the National Cotton Council of America have expressed their opposition to trade conflicts,” said Xu.

He said there is still a chance to reduce or eliminate the trade dispute. “The best solution I think is that both sides sit and talk to solve the problems. There could be a turning point at which disagreement will turn to agreement in the near future,” concluded Xu.

Ernesto Maurer, first vice president of CEMATEX, believed the trade conflicts would not much affect the textile industry. “Textiles is one of the oldest industries that have gone through crises and trade wars many times,” said Maurer. He believed the textile industry will adapt itself quickly to fix any problems, as textiles is not a single market, but a combination of various complex, flexible and versatile sectors that continually deal with different challenges.

Cooperation passes through barriers

Conflict is not a main theme of the manmade fiber and nonwoven machinery industry, said Xu. Industry players showed increasing interest in international cooperation at ITMA ASIA + CITME 2018 and believed by doing so they would overcome difficulties caused by negative impacts such as trade disputes. They are strengthening their competitiveness through cooperation with their international counterparts and competitors.

An example is that of Switzerland-based Oerlikon, which declared during the exhibition that its nonwoven business unit will work with China-based Hunan Shaoyang Textile Machinery (Shaoyang), a subsidiary of the state-owned China Hi-Tech Group Corporation (CHTC), for selling spunmelt nonwoven lines for hygiene applications to markets outside China.

Oerlikon will contribute its know-how in plant engineering and acquire CE (Conformité Européene) certifications for Shaoyang’s production and export of spunmelt lines, and will also be responsible for the product and process guarantees and provide customer service outside China.

Shaoyang will provide its spunmelt plant technologies, and will accelerate its international expansion with the help of Oerlikon’s technologies and experience, according to Yang Jianjun, general manager of Shaoyang.

from the organizers of ITMA ASIA + CITME 2018.

This is not the first international cooperation by Chinese manufacturers: over the past decade the Chinese manmade fiber, nonwoven, and machinery industries have intertwined deeply with the global market through partnerships, acquisitions, agents and building overseas facilities.

Acquisitions have helped Chinese companies fulfill their goals for technologies, brands and raw materials. In August 2011 CHTC formed the Autefa Solutions Group through purchasing three former Oerlikon Carding Division companies: Autefa Automation (now Autefa Solutions Germany), Oerlikon Neumag Austria (now Autefa Solutions Austria) and Oerlikon Neumag Italy (now Autefa Solutions Italy). CHTC hoped the acquisitions would combine the technologies and brands from Oerlikon to increase its market share.

Other acquisitions and mergers followed. In May 2018 China-based Highsun Holdings Group, a leading polyamide (PA) producer, purchased Fibrant and 60% of the shares of Fibrant China. Fibrant has an annual capacity of 680,000 tons of caprolactam, the raw material of PA, in Europe and China. The acquisition increased Highsun’s caprolactam capacity to 1.08 million tons per year, strengthening its position in the PA industry.

Working with local agents in overseas market is another common way for international cooperation. Many Chinese manmade fiber, nonwoven, and machinery manufacturers have set up sales channels with local agents in South Asia, Southeast Asia, the Middle East and other regions. This is especially true when it comes to smaller markets, such as machine parts. “A machine part deal is usually much smaller than that of a whole machine, and the requirements often vary widely, so our business mostly relies on local agents, who have extensive local channels and abilities,” said Zhang Hua, manager of a Chinese textile machinery company that sells manmade fiber and textile machine parts to the South and Southeast Asian market, mainly India.

Large Chinese companies often make deals directly with their customers at major shows such as ITMA ASIA + CITME. But they also need local agents to complement their business. Most of them have close connections with agents in markets that are difficult to reach fully. Through direct sales and the help of agents, overseas markets have become an indispensable part of the revenues of many Chinese companies. For example, Hi-Tech Heavy Industry (HTHI), another CHTC subsidiary, said 30% of its revenues of CNY1.2 billion ($180 million) in 2017 were from overseas markets, according to Li Juanyong, HTHI vice general manager.

Chinese companies have also set up overseas production facilities to extend their global reach. In 2014 Cixi Jiangnan Chemical Fiber established its first facility for recycled polyester staple fibers in South Carolina, USA. Other Chinese manmade fiber and machinery companies, who preferred to remain anonymous, told International Fiber Journal they are building production facilities in the USA, Southeast Asia and other places in the world.