By Haydn Kriel, R&D Manager; Dr. Megan Coates, Senior Scientist; and Dr. Eugene Smit, CEO, The Stellenbosch Nanofiber Company (Pty.) Ltd. (SNC)

Nanofibers have a range of applications in medicine, cosmetics, environmental monitoring, energy generation and the manufacture of smart materials. The high surface area-to-volume ratio of these nanomaterials is highly beneficial for drug delivery and catalysis, and their controllable pore sizes, that can be tailored to selectively exclude components like bacteria or pollutants, makes nanofiber webs ideal for filtration, tissue engineering and wound care. Nanofibers are also versatile in that additives can be encapsulated within the fibers or coated on to the surface. The choice of the polymer and the nanofiber dimensions can be changed to obtain specific material properties.

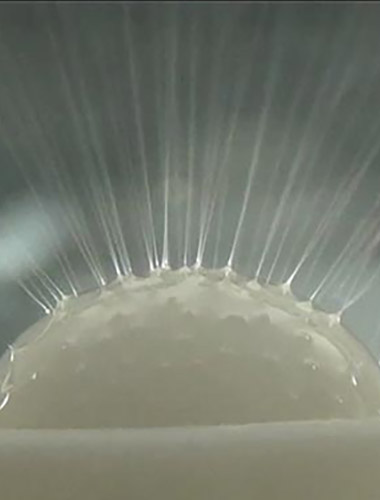

Large-scale production of nanofibers has been limited by the low production rates achieved through traditional methods, meaning that nanofibers have not been utilized to their full potential. SNC, a materials science company based in Cape Town, South Africa, was formed in November 2011 as a spin-off company from the University of Stellenbosch with the goal of commercializing high throughput electrospinning technology. At the core of SNC’s nanofiber technology is a free-surface electrospinning technology called Ball Electrospinning or SNC BESTTM. This technology involves rotating a ball in a polymeric solution so that the ball is coated by a thin layer of the solution, and applying a high voltage to this solution. When processing parameters are correctly set, multiple liquid jets eject spontaneously from the surface of the polymer solution on the ball surface. These liquid jets are electrically charged and whip chaotically. The whipping jets undergo stretching and thinning and in the process evaporation of the solvent occurs, creating solid fibers that are almost infinite in length but have fiber diameters into the nanoscale. What is unique about this technology is that the jets self-organize on the ball surface, creating a massively parallel and high-throughput electrospinning system. The technology has been widely patented.

SNC’s pilot scale production machine demonstrates the scalability of the SNC BEST technology, with some polymer-solvent systems yielding up to 1-kg/h production rates. Most of SNC’s current commercial projects are focused on medical applications, including wound dressings, tissue engineering and drug delivery. For these applications SNC primarily spin thick, freestanding nanofiber sheets without a carrier substrate.

Versatility

One of the great benefits of using electrospinning to produce nanofibers is that one can include various additives into the fibers by including them into the precursor solution. Furthermore, many materials can be electrospun at room temperature. These options can therefore be utilized on SNC BEST to create nanofibers with additives such as nanoparticles, pharmaceutical components such as antibiotics, antimicrobials, growth factors, peptides and many others.

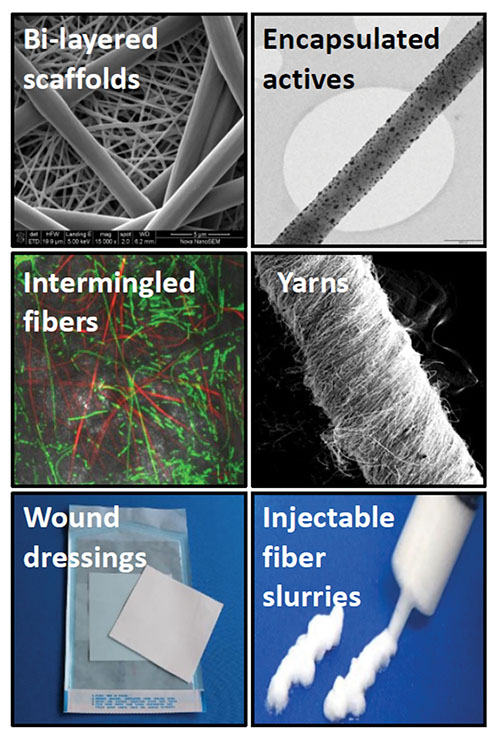

With SNC BEST multiple materials can be spun simultaneously and it is possible to create nanofiber structures with fibers of different materials arranged in multiple layers, or blended intimately into the same web. These include bi-, multi- or gradient-layered nanofiber materials with tailored fiber diameters in each layer, blended webs consisting of two or more polymers intermingled into the same web, composite material or multi-component fibers with encapsulated additives and active ingredients and nanofiber substrate coatings. SNC can also chop these large volumes of nanofibers up to form short fiber slurries. The low diameters of nanofibers mean that even when they are chopped to fiber lengths that are only a few tens of microns long, one still gets fiber fragments with high aspect ratios and in biological environments they still retain their bio-mimicking characteristics. The slurry format enables the use of nanofiber materials in various wet processable formulations, such as injectable drug delivery vehicles, or formulation additives in cosmetics creams and other applications.

To utilize the existing infrastructure of the textile industry, SNC has also developed IP for creating nanofiber yarns, which will be scaled up at a later stage. This will allow woven, knitted and embroidered structures to be made solely of nanofibers for mechanically demanding applications.

SNC has a growing list of materials that have been successfully spun into nanofibers. A lot of the company’s development has been driven by specific commercial interest, so this list is not exhaustive, but has been primarily evolved through specific commercial projects. Most of this development activity in the wound care, drug delivery and regenerative medicine is reflected by the presence in this list of many medical grade polymers like PCL, PLGA, and PLA. More industrial polymers like PVOH, PAN, PVDF, etc., and also natural polymers like collagen, gelatin, zein, and pullulan have been electrospun. SNC can also use typical sol-gel chemistries to create ceramic nanofibers of borides, nitrides, carbides and oxides as well as carbon nanofibers for applications in energy generation and defense.

Custom Products

The primary activity at SNC is the development of new spin formulations to create new nanofiber materials and products. To support this activity there is a competent and agile team of 8 materials scientists with backgrounds in chemistry, polymer science and textile science. Another important activity at SNC is the further development of its high throughput electrospinning nanofiber production and processing technologies. To do this requires engineers from various disciplines. It is for this reason that SNC works seamlessly and is actually co-located with a product development company that covers the entire product development life cycle. This company has a team of industrial designers, various engineers (chemical, mechanical, electrical, mechatronic), software developers and model makers, and has rapid processing facilities including 3D printing, CNC milling and lathing.

Enable products now

Whether one is a CTO, a technology transfer officer at a University or working on postgraduate studies, SNC works closely with clients to develop new, or evaluate existing nanofiber product concepts and formulations. Development, from initial concept, through to final full-scale commercial manufacture, is performed on the SNC BEST technology platform. SNC offers standard service packages in which they will develop a first proof of concept, or evaluate the manufacturability of an existing formulation within 4 to 12 weeks, depending on the complexity of the product. Then, within a similar timeframe, they can scale it up for clients and manufacture small commercial trial volumes of the product. Importantly, during this scaling up process, while producing pre-commercial trial volumes for clients, SNC is able to gather and deliver critical data and commercial information for building client’s business case, such as estimated costs of manufacture of product, as well as machine size and capital layout needed for full commercial production.

Over the past three years, SNC has successfully worked with clients to develop wound dressings for burn wounds, tissue scaffolds for retinal pigment epithelium, injectable drug delivery vehicles for peptides, ceramic supports for catalyst materials in fuel cells, and many others. The success of some of these projects has required SNC to take the next step in the development path and implement ISO 13485, 9001 and cGMP at their facilities in Cape Town. SNC has completed the installation of ISO class 7 cleanrooms and are expecting to offer cGMP materials from May 2016.

For more information contact:

Stellenbosch Nanofiber Company (Pty.) Ltd. – SNC Fibers

Tel: +27 (21) 035 0446

Email: info@sncfibers.com

Website: www.sncfibers.com