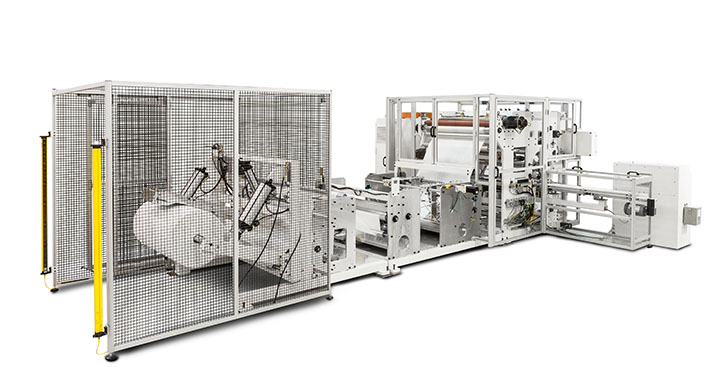

Your machinery and your people are two of your biggest costs and manufacturers are looking to automated solutions for more resilience to disruption in the future. ELSNER has developed automated solutions for products such as spiral-wound filters, canister wipes and surgical drapes. As a result, our customers are saving time, money and, most importantly, maintaining throughput.

Worker safety is paramount

Labor pressures are nothing new, but COVID-19 has made labor-related issues even more challenging. With a lack of options and smaller staffing, continuity to maintain throughput has been difficult for many manufacturers.

Automation offers the options needed to manage workflows even during a situation such as the coronavirus crisis. That is why despite budget shortfalls and declining productivity, many manufacturers are leaving room in the budget for investments in automated solutions as a long-term strategy for stability. There’s never been a time that more clearly highlights what NOT automating will cost you.

Beyond worker safety – more pain points automation helps conquer

- Improved Quality and Consistency: With less room for human error, there is a higher level of quality, precision, and accuracy. Automation makes repeatable tasks more consistent while freeing up your employees to concentrate on more complex tasks.

- Boost productivity: Automated processes produce many efficient, productivity-related boosts with more predictability.

- Space-saver: Automation helps you save floorspace with a more compact footprint which also helps more easily ebb and flow with inventory.

Why ELSNER Automation?

ELSNER is uniquely positioned in the marketplace to possess a broad view on manufacturing, having designed machinery for many diverse and complex markets, including over 20 years automating the process of manufacturing spiral wound filters. Our line of automated machinery removes manual processes and helps our customers manufacture a superior product.

- Automated wet wipes production: Coronavirus has resulted in huge increases in demand for canister wipes as manufacturers struggle to keep them on the shelves. Installing fully-automatic ENR-Series slitter rewinders has boosted our customers’ quality and efficiency to highest levels to-date, allowing them to keep up with the increased demands. Ultrasonic Tail Tie provides a glue-less option for controlling the tails on rolls with minimal compliance issues.

- Boosted productivity and quality of products for nonwoven medical disposables: We’ve alleviated manual labor associated with manufacturing complex surgical drapes as well as helped replace antiquated machines for the manufacture of rolled products such as undercast padding. ELSNER’s solutions dramatically decreases the number of workers needed, changes the daily routine of line operators to allow for flexibility to focus on quality assurance and downstream production.

- Quality gains for manufacturers of spiral wound membrane filters: We reduce the amount of manual labor involved in the process of building each spiral wound filter.

Want to know more about how ELSNER Automation can help you implement automation into your manufacturing? Contact us: eew@elsnereng.com.

This content is sponsored by: