The global demand for sustainable materials is growing, especially within the fiber and nonwoven sectors.

BioLogiQ, a pioneer in planet-friendly biopolymer technologies, has been at the forefront of this shift by developing nonwoven-grade materials that address environmental concerns without sacrificing performance.

These plant-based biopolymers can be combined with many traditional plastic resins to create application-specific, high-performing BioBlends. BioBlends provide companies with powerful value propositions for sustainability, including:

- Plant-based content

- Reducing and replacing the use of fossil fuel-based plastic

- Carbon/greenhouse gas footprint reduction

- Decreasing environmental persistence

- Shelf-stable material

- Versatility of leveraging existing equipment

- Increased softness

At BioLogiQ, the team has developed the XN product line with two new BioBlend grades incorporating 25% plant-based content. XN 25300 is tailored specifically for spunbond applications, while the XN 25200 is designed for yarn spinning. These innovations address the increasing demand for eco-conscious materials in sectors such as hygiene, medical, filtration, agriculture, automotive, protective packing, insulation, reusable bags, etc.

XN grade BioBlends are designed to mix with traditional spinning grade PP while offering an improved environmental profile. These materials meet or exceed the performance expectations of traditional nonwoven materials.

One of the key advantages of BioLogiQ’s solution is that it requires minimal modifications to current production processes, allowing manufacturers to transition to greener materials without significant disruptions or additional costs. This makes BioBlends attractive for companies seeking to reduce their environmental impact while maintaining operational efficiency.

Application Development and Testing

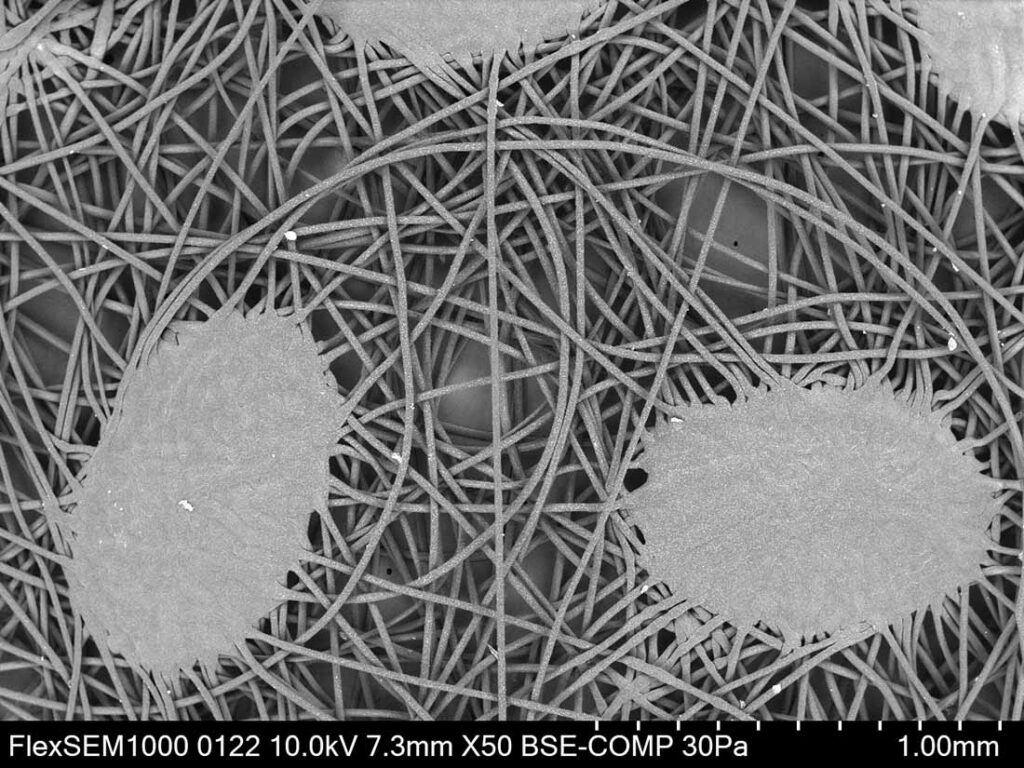

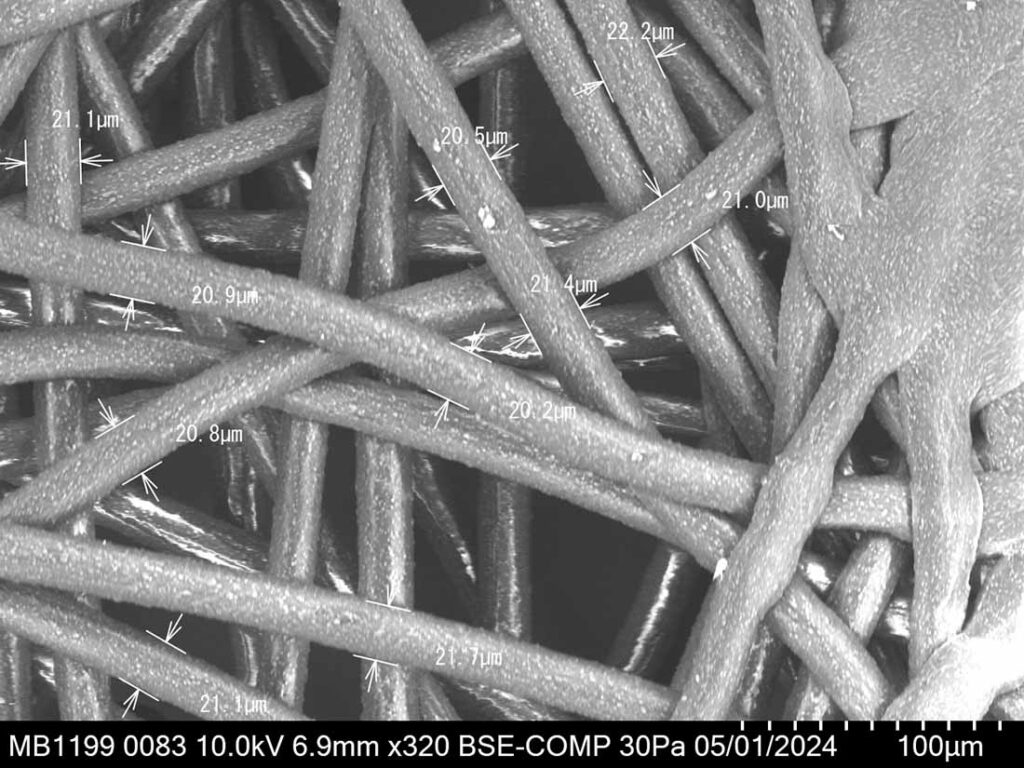

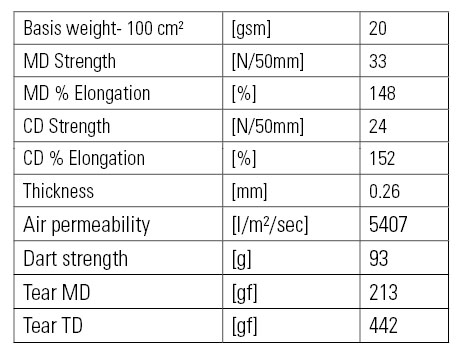

Our development of nonwoven-grade materials is complemented by rigorous application testing. We have worked with industry partner Hills, to conduct trials under real-world conditions, ensuring that our materials perform well across various parameters, including fiber distribution and strength. Properties of spunbond fabric are shown in Image 1.

For example, BioLogiQ has successfully completed trials making 20 gsm spunbond specifically targeting the hygiene market, as well as higher gsm fabric for isolation gowns, reusable bags, picnic tablecloths and similar applications.

BioLogiQ remains committed to advancing plant-based materials, with ongoing efforts to optimize performance for specific targeted applications. Our goal is to further expand the application of BioBlends in diverse sectors.

BioLogiQ has also conducted trials to produce melt-blown and bi-component fibers with the XN grades.

Bi-component fibers, in particular, can enable a higher bio-based content. Structures with polypropylene (PP) and polylactic acid (PLA) in the sheath and an XN BioBlend in the core have shown promise, with further optimization in progress.

Collaborative Efforts for Market Adoption

BioLogiQ recognizes that the development of sustainable nonwoven grades is only part of the challenge – the other is fostering market adoption. To this end, we are actively engaging with industry partners, manufacturers, and customers to showcase the capabilities of our materials. We believe that collaboration is key to accelerating the transition toward sustainable materials.

BioLogiQ’s advancements in nonwoven grade development represent a significant step forward for fiber solutions. Our commitment to innovation and collaboration will continue to drive us forward, as we strive to create nonwoven fabrics that meet the growing demand for sustainability while delivering the high performance that industries require.