Most people associate skiing accidents in alpine competitions with leg and ligament injuries. However, cut injuries from razor sharp ski edges can be as dangerous and in some cases life threatening.

The German Institutes of Textile and Fiber Research Denkendorf (DITF) now carries out cutting tests on materials for textile manufacturers and the International Ski Federation (FIS). Cut-resistant protection undergarment is awarded with a FIS label if the minimum recommended protection level is achieved.

FIS, textile manufacturers and the textile research center together have developed the FIS-DITF recommended minimum standard for the cut resistance of ski protection undergarment. The right undergarment improves the protection of athletes from severe cut injuries. To determine whether the undergarment meets the test specifications, the cut resistance of the material is rated using a 5-star scale.

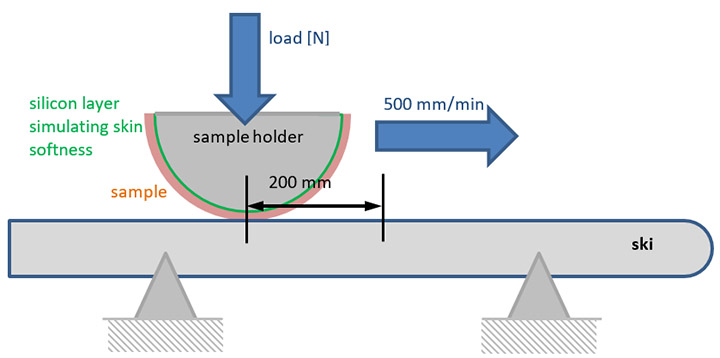

The scientists at the DITF check the compressive force at which the ski undergarment is cut through with a freshly and relevant grinded ski edge. The fabric has to withstand a minimum 20 centimeter cutting length at an angle of 0, 45 and 90 degrees. The test simulates a cut on an arm or leg with a compressive force of up to 500 N (50 kilograms).

The cutting speed is also precisely defined. For comparable data, the same type of ski is used for each test, the edges of which are always grinded in exactly the same way. “That was a big challenge in development,” said Thomas Stegmaier, head of the Competence Center for Textile Chemistry, Environment and Energy at the DITF. The star system, on the other hand, is easy to explain: If the undergarment withstands 100 N (10 kilograms) of pressure, it reaches the minimum level of 1 star. For every additional 100 N an additional level and star is reached. Up to 5 stars / levels are possible.