With the coronavirus (COVID-19) spreading worldwide, International Fiber Journal is tracking stories relevant to the textile fiber industry. Facemasks, personal protective equipment, medical supplies and wipes are among the fiber-intensive technologies particularly relevant to the COVID-19 response effort. And as manufacturers of these technologies and others struggle to meet global demand in the face of the growing COVID-19 pandemic, news stories are breaking quickly. Here we will post relevant news stories on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Matt Migliore at mmigliore@inda.media.

Most recent update: January 19, 2022

Texas Tech researchers author study using new standardized mask filtration testing to evaluate effectiveness of alternative facial coverings

Seshadri Ramkumar, a professor of chemical countermeasures and advanced materials in Texas Tech University’s Department of Environmental Toxicology, has co-authored a study utilizing standardized methods to evaluate common household fabrics as alternative materials for barrier face coverings. Olukayode James Ayodeji, a Ph.D. candidate in the Department of Environmental Toxicology, conducted the standardized tests measuring the filtration efficiency (FE) of different facial coverings.

Using mask filtration testing standards developed by the American Society for Testing and Materials (ASTM), Ramkumar and his team compared the performance of popular ready-made facial coverings, such as bandanas and neck gaiters, to alternative household materials including denim, cotton shirts, bedding and towels. Both categories of materials were measured against R95 masks, which offer the highest level of protection against viral particles.

While a material’s ability to filter out viral particles is paramount, breathability is an equally important consideration, Ramkumar said. Unfortunately, testing revealed an inverse relationship between filtration efficiency (FE) and breathability – for instance, while denim showed the highest FE, it also had the lowest breathability of all the household fabrics, rendering it unsuitable for facemask production. Ramkumar and his team took both parameters of FE and breathability into equal account when evaluating a material’s overall performance.

According to their study, the most effective ready-made facial coverings on the market are Velcro masks with carbon filters and surgical masks, while the least effective are fashion facemasks, single-layer face coverings, neck gaiters and bandanas.

The highest-performing household materials were thick cotton shirts and towels, indicating that multi-layered cotton facial coverings with proper fit are the most effective homemade mask alternative because they offer a measure of protection against viral particles without compromising breathability.

A combinatorial approach involving both a facial covering and a surgical mask with good fit would offer the wearer better protection against particle inhalation, Ramkumar said.

Ramkumar co-authored the paper, “Particle-Size-Dependent Filtration Efficiency, Breathability, and Flow Resistance of Face Coverings and Common Household Fabrics Used for Face Masks During the COVID-19 Pandemic,” alongside Texas Tech graduate students Olukayode James Ayodeji and Terrell A. Hillard, with the support of Texas Tech graduate student Mirza Khyum. The study was published in Volume 16 of the International Journal of Environmental Research earlier this month.

Source: tiehh.ttu.edu

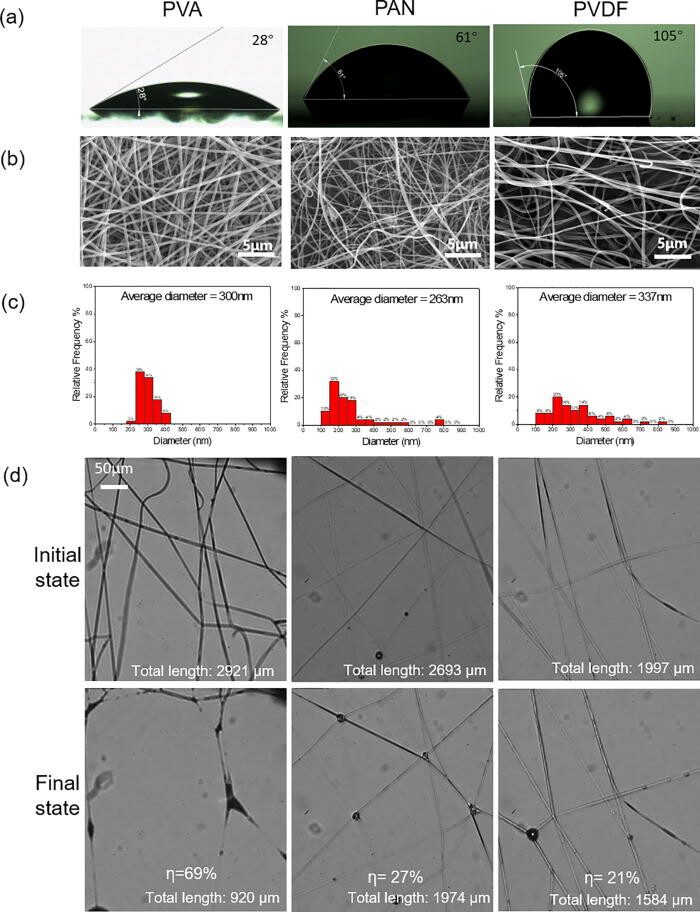

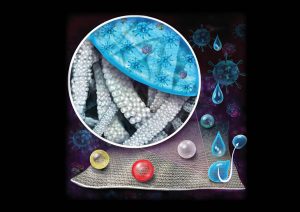

New research shows the interaction of water aerosol with nanofiber mesh facemask material

Facemasks made with nanofibers have drawn increasingly more attention because of their higher filtration efficiency, better comfort, and lower pressure drop. However, the interactions and consequences of the nanofibers and microwater droplets remain unclear.

New research published in the journal Physics of Fluids shows the evolution of fibers made of polymers with different contact angles, diameters, and mesh sizes under water aerosol exposure is systematically visualized. The images show that capillarity is very strong compared with the elasticity of the nanofiber. The nanofibers coalesce irreversibly during the droplet capture stage as well as the subsequent liquid evaporation stage. The fiber coalescence significantly reduces the effective fiber length for capturing aerosols. The nanofiber mesh that undergoes multiple droplet capture/evaporation cycles exhibits a fiber coalescing fraction of 40%–58%. The hydrophobic and orthogonally woven fibers can reduce the capillary forces and decrease the fiber coalescing fraction.

This finding is expected to assist the proper design, fabrication, and use of face masks with nanofibers. It also provides direct visual evidence on the necessity to replace face masks frequently, especially in cold environments.

Read the full story: https://aip.scitation.org/doi/full/10.1063/5.0061847 Source: https://aip.scitation.org/journal/phf

Livinguard Technology shows effectiveness against Indian Isolate of SARS COV 2 (COVID-19, wild version)

Livinguard, a developer of protective facemasks with COVID-19-deactivating properties, announced its technology has been proven effective by an independent laboratory against the Indian isolate of SARS COV 2 – Covid 19, wild version. The tests were carried out by the Indian National Institute (NII) of Immunology on Livinguard’s facemask fabric. Results indicate that each layer of the Livinguard mask has an average of > 99% effectiveness against the Indian isolate of SARS COV 2 (wild version). The principle underlying the Livinguard technology is the deactivation of microbes including bacteria and viruses*. The technology applies a positive charge at the molecular level to textile surfaces, making them more powerful than the negative charge of microbes. Therefore, microbes are deactivated when they encounter textiles treated with Livinguard Technology. Textiles treated with Livinguard Technology have also been proven to deactivate viruses, including SARS-CoV-2* (the virus that causes COVID-19) by researchers at the Free University Berlin and the University of Arizona. Furthermore, Livinguard Technology is safe for humans and the environment. Speaking about the test results, Sanjeev Swamy, Livinguard CEO, said “We are making everything possible to address the demand from the increasing number of regions that are making it mandatory to wear a mask outside and inside again. Over the past 24 months, Livinguard has been tirelessly updating its self-disinfecting technology and this is yet another example of the company rising to the challenge in a race against the clock.” The company is now focusing on pivoting its production facility to scale the delivery of its sustainable hygiene technology worldwide. Source: livinguard.com

US DoD, DHS award $6.5 M to US Cotton to boost polyester-tipped swab production

The Department of Defense (DOD), on behalf of and in coordination with the Department of Health and Human Services, awarded $6.5 million to U.S. Cotton, LLC, a subsidiary of Parkdale, Inc., to increase domestic production capacity of the polyester-tipped swabs used in COVID-19 home test kits and mass testing settings. U.S. Cotton’s COVID-19 test swab is designed for hospital and laboratory settings and, when used at home, allows for an easier self-administered test. This industrial base expansion effort will allow U.S. Cotton to increase its production capacity from 92 million polyester swab tips per month to approximately 371 million polyester swab tips per month in Cleveland, Ohio, by May 2022 to support domestic COVID-19 testing. The DOD’s Defense Assisted Acquisition Cell (DA2) led this effort in coordination with the Department of the Air Force’s Acquisition COVID-19 Task Force (DAF ACT). This effort was funded through the American Rescue Plan Act (ARPA) to enable and support domestic industrial base expansion for critical medical resources. Source: defense.gov

NCTO welcomes Senate passage of U.S. infrastructure bill, funding to bolster domestic PPE supply

The National Council of Textile Organizations (NCTO), which represents U.S. textile manufacturers from fiber through finished products, issued a statement welcoming Senate passage of a bipartisan infrastructure bill that will provide billions of dollars in new spending with the aim of revitalizing the nation’s roads, bridges and railways and help reconstitute a domestic supply chain for personal protective equipment (PPE). “We commend the Senate for passing the bipartisan infrastructure bill, which will provide critical resources for our nation’s aging infrastructure and at the same time help incentivize the reshoring of personal protective equipment (PPE) production, an important priority of the U.S. textile industry,” said NCTO president and CEO Kim Glas. NCTO worked with congressional allies to include a version of the Make PPE in America Act, legislation co-sponsored by Senator Rob Portman (R-OH) and Senator Gary Peters (D-MI), in the infrastructure legislative package. The bill ensures all PPE purchased by the Departments of Homeland Security, Health and Human Services and Veterans Affairs are Berry Amendment-compliant; guarantees long-term contracts (a minimum of two years) to U.S. manufacturers; and creates a tiered preference for PPE made in the Western Hemisphere by our free trade partners using U.S. components, after domestic manufacturing capacity has been maximized. “We sincerely thank Senator Portman and Senator Peters for working to include their Make PPE in America Act in the infrastructure bill,” Glas said. “This bill will help onshore critical production of personal protective equipment (PPE) by guaranteeing long-term contracts for domestically produced PPE and ensuring that taxpayer dollars are utilized to bolster the federal purchase of American-made PPE.” Source: ncto.org

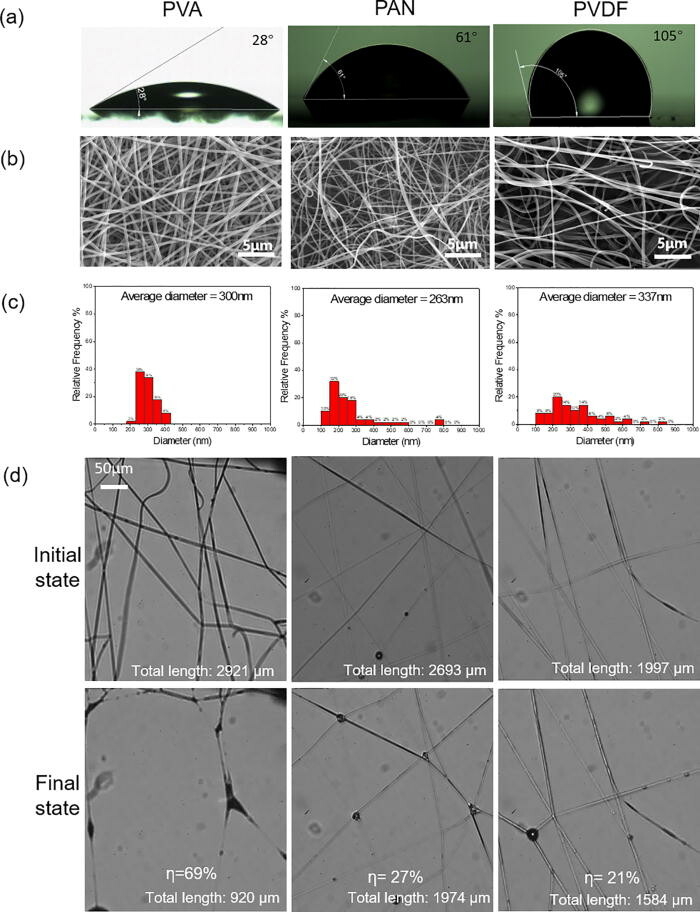

Asahi Kasei and Nara Medical University confirm 226nm UVC LED efficacy against SARS-CoV-2

Asahi Kasei and Nara Medical University announced the results of the efficacy of 226 nm ultraviolet-C (UVC) LEDs in the inactivation of the coronavirus that caused COVID-19, and its effects on animal skin cells. The results showed that 99.9% of the virus was inactivated by both 226 nm and 270 nm UVC LEDs and there was significantly less effect on animal skin cells. In the tests, 100 of the 226 nm UVC LEDs were placed on a panel in a 10×10 array. All of the UVC LEDs were created from the proprietary aluminum nitride (AIN) substrate and pseudomorphic aluminum gallium nitric (AIGaN) technology of Crystal IS. For comparison, a similar array of 270 nm UVC LEDs were also prepared. Liquid containing viable SARS-CoV-2 was injected into a Petri dish and then dried. The panel arrays were activated at an output of 440 μW/cm² . After, the virus was collected and the amount of contagion was measured by the plaque technique.  An additional experiment was conducted on mouse skin cells to estimate the damage that 226 nm UVC LED light has on animal skin compared with 270 nm light. The mouse skin cells were arranged in two layers which were then exposed to either 226 nm or 270 nm UVC LED light at a dosage of 100 mJ/cm² and 500 mJ/cm². After the exposure, the upper layer of cells was removed and the relative fraction of living cells in the bottom layer was evaluated by measuring the absorbance after applying an MTT reagent dye to the cells. The results show that the 226 nm UVC LED light had little to no effect at 100 mJ/cm² , and at 500 mJ/cm² there was less effect on the cells of the bottom layer. All experiments were conducted on the campus of Nara Medical University in Bio Safety Level 3 (BSL3) testing facilities. Airborne viruses or their effects on humans were not tested. Source: asahi-kasei.com

An additional experiment was conducted on mouse skin cells to estimate the damage that 226 nm UVC LED light has on animal skin compared with 270 nm light. The mouse skin cells were arranged in two layers which were then exposed to either 226 nm or 270 nm UVC LED light at a dosage of 100 mJ/cm² and 500 mJ/cm². After the exposure, the upper layer of cells was removed and the relative fraction of living cells in the bottom layer was evaluated by measuring the absorbance after applying an MTT reagent dye to the cells. The results show that the 226 nm UVC LED light had little to no effect at 100 mJ/cm² , and at 500 mJ/cm² there was less effect on the cells of the bottom layer. All experiments were conducted on the campus of Nara Medical University in Bio Safety Level 3 (BSL3) testing facilities. Airborne viruses or their effects on humans were not tested. Source: asahi-kasei.com

Everfresh from Aksa Akrilik neutralizes coronavirus by 97.48%

Aksa Akrilik announced its antimicrobial fiber product Everfresh, for products ranging from facemasks to home textiles, is capable of neutralizing coronavirus by 97.48% within 30 minutes, according to the company’s test data. Everfresh utilizes a zinc compound in the fiber with no impact on human health or skin, allowing it to be used for carpets, blankets, quilts, beddings, towels and pillows, especially in hotels, mosques and dormitories. Everfresh maintains its microbial activity and its impact against coronavirus after repeated washing.

“With our new product Everfresh, we are delighted to respond to the health-sensitive needs of our society,” said Cengiz Taş, Aksa Akrilik board member and general manager. “Everfresh once again made a difference in textile products by eliminating coronavirus by 97.48 percent in half an hour. Thanks to its zinc compound, Everfresh provides antimicrobial properties to the products and reduces the need to wash the product by preventing bad odors.” Source: aska.com

Biden Administration awards contracts for up to 22.2 million US-made facemasks

The National Council of Textile Organizations (NCTO) reported that the Biden Administration has awarded two contracts to Parkdale Mills and Ferrara Manufacturing Inc., as part of President Biden’s pledge to procure millions of domestically made facemasks for community health centers, food pantries and soup kitchens across the country. North Carolina headquartered Parkdale Mills, the nation’s largest cotton yarn spinner, has partnered with Ferrara Manufacturing, a tailored clothing company based in New York City’s garment center, whose workforce is union represented by Workers United/SEIU, to manufacture over 17 million reusable masks. The government said it could purchase up to a maximum of 22.2 million masks under the two contracts. The masks will be Berry Amendment compliant, and thus 100% U.S.-made. Ferrara Manufacturing and Parkdale Mills will contract with additional U.S. companies across the manufacturing supply chain, employing nearly 5,000 American workers as a result of these awards. Parkdale will be utilizing yarn from their facilities in NC, VA, and GA and Ferrara will deploy their cut and sew operations in New York City. Source: ncto.org

HomTex receives FDA Emergency Use Authorization for Level 1 surgical masks; expects to begin production of N95 masks soon

HomTex, an Alabama-based textile manufacturer, announced it received FDA Emergency Use Authorization for its Level 1 surgical masks. HomTex manufactures three-ply disposable masks and reusable cloth masks, which it supplies to the U.S. Capitol, and it will begin production of NIOSH N95 masks in a new plant in Selma, Alabama. HomTex’s made-in-America masks are produced in facilities in Cullman and Mobile, Alabama; Tennessee; South Carolina; and North Carolina. Jerry Wooten, CEO of HomTex, said, “When I say made in America, I mean every component sourced in the US and made in the US. We believe that ramping up domestic manufacturing of PPE products is a national imperative from a safety, economic, and national security perspective, and HomTex is proud to meet that challenge.” HomTex has the capacity to produce 700 million surgical 3-ply masks and 20 million NIOSH N-95 masks annually. HomTex’s new manufacturing facility in Selma is expected to open in fall of 2021, creating 300 jobs. HomTex, Inc., a manufacturer of textile bedding products, was founded in 1987 by Jerry Wootten and is headquartered in Cullman, Alabama. Today, HomTex has a nationally recognized brand of bedding product, DreamFit and produces FDA-approved PPE masks. HomTex has over 400 employees with over a million square feet of domestic production and distribution. HomTex is a Certified Minority Business Enterprise (Certificate #SR01666 certified by the NMSDC ). Source: homtex.com

Test results show Fiber Bond VE3 chemistry inactivates 99.9% of SARS-CoV-2 in HVAC systems

Fiber Bond announced the release of its VE3 Technology, an engineered chemistry that inactivates SARS-CoV-2, according to test results. Lab testing concludes that Fiber Bond’s VE3 Technology inactivates 99.99% of the airborne SARS-CoV-2 virus within 15-minutes. The VE3 Technology is a value-added chemistry, developed in-house at Fiber Bond to help stop the spread of COVID-19 in any facility with an HVAC system. The patent-pending VE3 Technology captures and inactivates the SARS-CoV-2 virus within the nonwoven media of Fiber Bond HVAC air filters. Fiber Bonds VE3 Technology was “evaluated for its ability to inactivate SARS-coronavirus type 2” by Microbac Laboratories, Inc., and “demonstrated a 99.99% inactivation of the virus challenged.” In March 2020, shortly after the start of the COVID-19 pandemic, Fiber Bond’s team of engineers focused their expertise on the conceptualization and production of an HVAC-compatible filtration product with the ability to capture and eliminate the SARS-CoV-2 virus within an engineered binder system. In-house research and development of VE3 Technology successfully and swiftly progressed at the Fiber Bond facilities in Michigan City, IN. And, by late 2020, Microbac Laboratories, tested the VE3 Technology for capturing and inactivating the airborne SARS-CoV-2 virus. “This technology development undertaken by our Fiber Bond technical team is a testament to our ongoing efforts on providing products that enhance air quality. The VE3 technology is focused on providing an additional safeguard against airborne viral particles, specifically COVID-19, and is a great complement to our product portfolio that already includes antimicrobial products. Cleaner air helps to maintain a safer environment for all of us,” said Greg Wilkerson, president & CEO of Fiber Bond and Blocksom & Company. The VE3 Technology is designed to work in residential, commercial, and industrial HVAC systems to provide equivalent protection against SARS-CoV-2 in high-efficiency air filters. The VE3 Technology is added to the adhesive bonding agent used in the manufacturing of Fiber Bond’s nonwoven filtration media for HVAC applications. VE3 also includes Fiber Bond’s exclusive EPA-certified Spor-Ax antimicrobial agent for eliminating fungal bacteria growth on the filter media. Source: fiberbond.net

Sukano Antiviral Masterbatch shows efficacy in reducing SARS-CoV-2 on textile surfaces

Sukano’s Antiviral Masterbatch has undergone additional testing, following up a round of testing in 2020 confirming the effectiveness of its masterbatch against feline coronavirus and influenza H1N1. The company has now run extensive tests against SARS-CoV-2 in an external laboratory specialized in microbiological testing. The results confirmed the effectiveness of the Sukano Antiviral Masterbatches – within the first 30 minutes up to 99.9% reduction of SARS-CoV-2 on a fabric’s surface and a reduction up to 99.98% within 2 hours. “We extended the tests beyond PET and PA to PP and PLA, and also tested specifically against SARS-CoV-2 according to ISO standards,” said Michael Kirch, global head of R&D for Sukano. “These tests confirm the same robust and efficient results. We are delighted with the outcome of the tests and have now confirmation on the deactivation of the viruses on fabric surfaces by a certified and specialized external laboratory, giving our customers additional trust and confidence to use our high-performance additive masterbatch in their applications.” Sukano’s Antiviral Masterbatches work by directly integrating an antiviral additive into the polymer, using proprietary formulation and technology, eliminating the need for secondary processing steps. Sukano Antiviral Masterbatch allows the final product to remain fully recyclable without a loss in performance, contributing to the common goal of a circular economy. The Antiviral Masterbatch is extremely efficient and this powerful technology remains present and effective throughout the life of the product. The antibacterial efficacy was tested and remained after up to 200 washing cycles at 40 C. All this is possible without impacting the fibers’ physical properties or yellowing. The active ingredient used in Sukano’s Antiviral Masterbatches is a registered preservative in the EU, Switzerland and United States. However, to claim antiviral effect and promote this in the final product, producers using Sukano’s Antiviral Masterbatches must test the final product, have the results confirmed by a specialized external laboratory, and must comply with local legal regulations. Source: sukano.com

SGS introduces IC Mark for reuseable facemasks in U.S. and Canada

As more and more people around the world rely on the use of face masks to prevent the spread of COVID-19, SGS launched the first Independently Checked Mark (IC Mark) for reusable fabric masks, a new way for consumers in the U.S. and Canada to know if these products conform to industry and regulatory requirements. The new IC Mark tests and verifies products using key performance attributes from the recently published industry consensus standard, ASTM F3502 Standard Specification for Barrier Face Coverings.  The Mark gives manufacturers and retailers a greater ability to demonstrate their focus on quality and performance, to create and supply products that meet or exceed the minimum legal requirements. In addition, its widespread use will provide consumers across North America with at-a-glance assurance that products satisfy safety and performance claims, and meet regulatory standards. “Consumers need reassurance from manufacturers and retailers that the reusable fabric masks they are using are performing as intended”, says Matthew McGarrity, Senior PPE Technical Manager for SGS North America. He adds, “They also need to know important criteria such as how many laundering cycles their masks can go through until they are no longer of use.” SGS in North America, along with other industry experts, helped draft the ASTM F3502 Standard Specification for Barrier Face Coverings. Its criteria include minimum design, performance, and care/use instructions. Working with leading experts in textiles, filtration and restricted substances, SGS drafted various domestic and mask/face covering guidelines. The IC Mark approval process tests for:

The Mark gives manufacturers and retailers a greater ability to demonstrate their focus on quality and performance, to create and supply products that meet or exceed the minimum legal requirements. In addition, its widespread use will provide consumers across North America with at-a-glance assurance that products satisfy safety and performance claims, and meet regulatory standards. “Consumers need reassurance from manufacturers and retailers that the reusable fabric masks they are using are performing as intended”, says Matthew McGarrity, Senior PPE Technical Manager for SGS North America. He adds, “They also need to know important criteria such as how many laundering cycles their masks can go through until they are no longer of use.” SGS in North America, along with other industry experts, helped draft the ASTM F3502 Standard Specification for Barrier Face Coverings. Its criteria include minimum design, performance, and care/use instructions. Working with leading experts in textiles, filtration and restricted substances, SGS drafted various domestic and mask/face covering guidelines. The IC Mark approval process tests for:

- Breathability

- Particle filtration efficiency

- Labeling

- Strap attachment strength

- Service life claims

- Restricted substances

- Flammability

Source: sgs.com

NCTO applauds Biden administration’s executive orders to solidify US supply chains for PPE and medical supplies

National Council of Textile Organizations (NCTO) president and CEO Kim Glas has issued statements supporting President Joe Biden’s recent executive orders aimed at solidifying U.S. supply chains for PPE and medical supplies, as well as actions outlined in the administration’s “National Strategy for the COVID-19 Response and Pandemic Preparedness.” “We commend President Biden for taking action in his first days in office to strengthen our domestic supply chain and manufacturing base with a ‘Made in America’ executive order directing the federal government to spend taxpayer dollars on American-made goods produced by American workers using American-made components,” said Glas. Increasing the domestic procurement threshold and the price preferences for domestic goods under the current “Buy American” law will bolster domestic production and stimulate more investment in U.S. manufacturing, said Glas. “We believe it is critical that taxpayer dollars are used to invest in American manufacturing and our workforce,” said Glas. “It is essential that we close loopholes in our Buy America laws, expand application and product coverage of domestic content rules, and close unnecessary contract waivers that undermine American manufacturing and its workforce.” Glas also thanked Senator Sherrod Brown (D-OH) and Representative Kathy Manning (D-NC) for their leadership in sending a recent letter to President Biden, requesting the president prioritize “Made in America” personal protective equipment (PPE) purchases and outlining key steps the administration can take to produce and procure quality American-made PPE for frontline workers. In addition, NCTO issued a statement welcoming President Joe Biden’s action plan and COVID-19 response, accompanied by a series of executive orders, including an order signed today to strengthen U.S. supply chains by directing federal agencies to use the Defense Production Act (DPA) to address shortages of personal protective equipment (PPE) and related vaccine supplies. “We are closely reviewing President Biden’s national strategic plan to confront the pandemic and welcome the executive order signed today to strengthen our supply chains by directing all federal agencies to use the Defense Production Act to address shortages of personal protective equipment, vaccine supplies and essential products,” said Glas. “These are important steps that will help ramp up critical manufacturing of these essential PPE products and other critically needed supplies like tests and vaccines.” American manufacturers have been at the forefront of the effort to build a domestic PPE supply chain since the onset of the COVID-19 pandemic. The U.S. textile industry retooled production and operations virtually overnight, producing millions of face masks, isolation gowns, testing swabs and other critical medical textiles. Since its inception, the DPA has been utilized by the Department of Defense to make critical investments in domestic textile manufacturing infrastructure and capacity, creating private-public partnerships through the government’s capital investments under the DPA and guaranteeing purchases through long-term contracts. “We applaud President Biden’s action today and anticipate further steps including a reported order that will seek to strengthen government procurement of U.S. products in the coming days,” said Glas. “We appreciate President Biden outlining in the ‘National Strategy for the COVID-19 Response and Pandemic Preparedness’ a series of actions and steps the administration will undertake to deploy and manufacture the vaccine and other essential products.” The NCTO has produced a video campaign that outlines steps the Biden administration and Congress must take to re-shore the production of personal protective equipment (PPE) and the entire supply chain for critical products:

To read the Biden administration’s COVID-19 action plan: whitehouse.gov/wp-content/uploads/2021/01/National-Strategy-for-the-COVID-19-Response-and-Pandemic-Preparedness.pdf To read NCTO’s critical steps that are necessary to strengthen the U.S. supply chain for essential products: ncto.org/ncto-outlines-key-priorities-for-the-incoming-biden-administration-and-congress-to-strengthen-the-u-s-supply-chain-for-essential-products/ Source: ncto.org

Porex medical device filtration materials shown to protect against spread of bacteria and viruses

Porex is one of the first in industry to initiate VFE testing for its porous polymer-based materials; results show components protect against certain aerosolized viruses To address the spread of healthcare-associated infections (HAIs) from aerosolized viral particles, Porex Corporation, a global leader in porous polymers, has pioneered the use of VFE testing methods for materials used in medical device design. Likely the first in the porous polymer material science industry to run the new analysis on filtration media, the components were able to consistently obtain a 99.9987% VFE score, showing that its materials effectively help to protect healthcare workers and patients from aerosol-based viruses potentially present in medical settings. Porex initiated VFE testing for its materials after observing the needs of its customers, which frequently fielded concerns from patients and healthcare workers seeking information that the components used in various equipment procedures would not pose risks of a HAI contraction. Nearly one in 31 hospital patients acquires a HAI—and these infections lead to an estimated 99,000 annual deaths in American hospitals alone, according to the Centers for Disease Control and Prevention (CDC). Healthcare workers face similar—if not greater—threats due to frequent exposure to viral pathogens. “The pandemic has magnified what was already a pressing issue in healthcare settings around the world, which is that inadequate filtration materials put patients and professionals at risk of contracting dangerous viruses,” said Avi Robbins, vice president, global product development and R&D at Porex. “We took the step to lead the materials industry into VFE testing to validate efficacy, and we are thrilled to confirm that our filtration and venting components are trustworthy and reliable for blocking viral particle spread.” Porex develops venting and filtration solutions by leveraging several core technology platforms such as sintered particles, bonded fiber, PTFE and Oxyphen track-etched membranes. Filtration and venting media from Porex are suitable for suction canisters, catheters, syringes and other medical equipment utilized in aerosol-generating medical procedures. Source: porex.com

Polygiene acquires Addmaster, expanding antimicrobial technology footprint

Sweden-based company Polygiene buys British Addmaster Holdings Limited, expanding its footprint for antimicrobial solutions for both soft and hard surfaces. The purchase price was SEK 374 million. “It’s great to have the backing of the EGM. We can now focus on merging the two companies and getting the organization established. The acquisition will allow us to offer the market a comprehensive solution of antimicrobial functions for both soft surfaces such as textiles and hard surfaces such as floors, handles, kitchen and bathroom fittings in public spaces. This reduces the need for washing and cleaning, therefore lessens our environmental impact,” said Ulrika Björk, CEO of Polygiene, which was established following the 2004 SARS pandemic through a spin-off from the Perstorp Group. Polygiene’s antimicrobial and odor management products include ViralOff, BioStatic and OdorCrunch. ViralOff, launched in the spring, has performed the best. According to ISO standards-based testing, it is over 99 percent effective at breaking down viruses such as SARS-CoV-2, which causes the disease COVID-19, within two hours. Addmaster Ltd is a leading supplier of high-performance, technically innovative additives to the plastics, textile, paper, paints and coatings industries. The company provides additive masterbatches, liquid or powder dispersions for any application. Biomaster Antimicrobial Technology and Biomaster Protected are Registered Trademarks of Addmaster (UK) Ltd. Biomaster Protected products are tested to ISO standards and are proven to be effective against over most common types of harmful bacteria and specific viruses including SARS-COV-2. Source: https://polygiene.com/

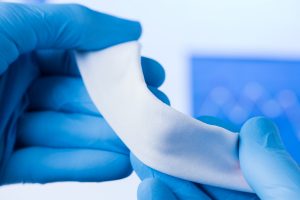

Standard Textile, Cleveland Clinic collaborate to develop reuseable facemask

Standard Textile, a global manufacturer of healthcare, hospitality, and consumer products, and Cleveland Clinic will collaborate to produce a non-medical grade, reusable facemask that is designed for comfort and customization. Standard Textile will sell the facemasks on its consumer website, standardtextilehome.com.

Standard Textile’s and Cleveland Clinic’s respective innovation teams collaborated to design the non-medical facemask, which will bear the inspirational message “HOPE” after Hope Hospital, a temporary hospital in the Sheila and Eric Samson Pavilion on the Health Education Campus of Case Western Reserve University and Cleveland Clinic. In April, Cleveland Clinic transitioned the Samson Pavilion to a temporary hospital to meet the potential needs of patients and the community in the event of a surge of patients with COVID-19. The building was converted back to the Health Education Campus for the fall semester. The reusable facemask offers enhanced comfort with its 100% cotton construction and breathability with its mesh lining. Adjustable ear loops and a neck strap add convenience of use, while its filter pocket and removable nose clip offer customization options. Standard Textile and Cleveland Clinic plan to produce custom-branded versions of the facemask for key partners looking to outfit their employees and customers with an enhanced, non-medical facemask. Source: standardtextile.com

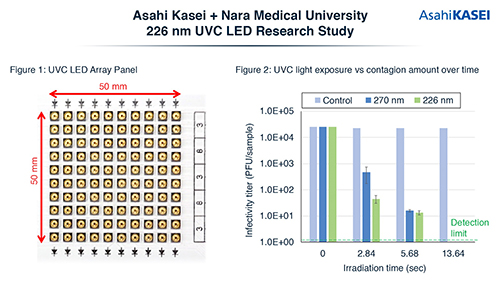

ITMF survey shows COVID-19 has had negative impact on textile turnover, but expectations are improving

The International Textile Manufacturers Federation (ITMF) conducted its 6th ITMF Corona-Survey among ITMF members and affiliated companies and associations about the impact the COVID-19 pandemic has had on the global textile value chain. In total, 159 companies from around the world participated. In comparison to the 5th ITMF Corona-Survey (September 5th – 25th, 2020), the turnover expectations have improved by 4 percentage points from -16% to now -12% compared to 2019 (Graph 1).

For 2021 and the following years, turnover expectations have overall improved slightly . On average, companies are expecting a small improvement from -1% (5th survey) to +3% (6th survey) compared to 2019. Also, for 2022 and 2023 the outlook has improved slightly from +9% (5th survey) to +11% (6th survey) and from +14% (5th survey) to +15% (6th survey), respectively. The turnover expectations for 2024 – compared to the 2019 levels – have not changed (+18% in the 5th and 6th survey). Source: itmf.org

Mask-Alliance Bavaria certifies FFP2 facemask; production to begin at Zettl Group plant in Weng

Founded in May 2020, in response to the COVID-19 pandemic, the Mask-Alliance Bavaria established a complete value chain for the manufacture of facemasks in Germany. In its latest development, the Futurus facemask has been certified as an FFP2 protective mask. In December, production will start at alliance member Zettl Group’s plant in Weng, Bavaria. Since the beginning of this initiative to produce mouth-nose protective facemasks, the founding members of the Mask-Alliance Bavaria – PIA Automation (automation specialist from Amberg), Sandler Group (manufacturer of high-tech nonwovens from Schwarzenbach/Saale) and Zettl Group (leading supplier in the field of automotive interiors) – had been working to produce certified FFP2 masks in Bavaria.

On December 3rd, Jörg-Timm Kilisch, Managing Director of DEKRA Testing and Certification GmbH, officially presented the certificate at the Zettl Group company site in Weng, Landshut district. FFP2 or FFP3 masks are particularly recommended as personal protective equipment for healthcare workers who are exposed to an increased risk of infection in their work. The quality of the filter medium, the mask design, the fit and the available filter area are decisive for the classification of the product. In joint development work and close cooperation with the new association member DEKRA, the certification process was successfully completed at the end of October. The fully automated production lines in Weng will now produce up to 6 million Futurus masks per month. An expansion of the production capacity to up to 10 million masks per month is already being planned. The Mask-Alliance Bavaria is thus expanding its contribution to securing the supply of these important medical products. Source: masken-verbund-bayern.de

WHO issues COVID-19 mask guidance; references AATCC standards

The World Health Organization (WHO) now advises manufacturers wishing to produce product with consistent performance to follow guidance from AATCC or other standards organizations. WHO issued interim guidance for “Mask use in the context of COVID-19,” and the annex provides information on fabric face coverings, including reference to AATCC M14, Guidance and Considerations for General Purpose Textile Face Coverings: Adult. This WHO guidance, which is an update of the guidance published on 5 June 2020, includes new scientific evidence relevant to the use of masks for reducing the spread of SARS-CoV-2, the virus that causes COVID-19, and practical considerations. It contains updated evidence and guidance on the following:

- mask management;

- SARS-CoV-2 transmission;

- masking in health facilities in areas with community, cluster and sporadic transmission;

- mask use by the public in areas with community and cluster transmission;

- alternatives to non-medical masks for the public;

- exhalation valves on respirators and non-medical masks;

- mask use during vigorous intensity physical activity;

- essential parameters to be considered when manufacturing non-medical masks (Annex).

AATCC staff participated in a series of weekly meetings of the WHO group that compiled the latest guidance. The language and thresholds for several essential face covering parameters are consistent with the recommendations in AATCC M14. While various national and regional bodies have issued similar guidance, AATCC M14 was the first global standard to address general use face coverings. The AATCC recommendations for filtration and breathability are similar to those cited in other standards. Further alignment of standards was discussed and encouraged by the WHO advisory group. In addition to testing parameters, AATCC M14 includes practical consideration for fabric and design selection. This is particularly valuable for manufacturers pivoting from unrelated products with minimal background in textiles or public wellness. WHO also references AATCC TM100, Test Method for Antibacterial Finishes on Textile Materials: Assessment of, for antibacterial testing, though the organization advises caution in making antimicrobial claims for non-medical face coverings. AATCC M14 is under the jurisdiction of committee RA113, Emerging Technologies Test Methods. The committee met in November and plans to develop a new standard to address the specific needs of face coverings for children. Participation in AATCC research committees is open to all. WHO Guidance: https://apps.who.int/iris/rest/bitstreams/1319378/retrieve AATCC M14: https://members.aatcc.org/store/m014/3085/ AATCC COVID Resources and Information: www.aatcc.org/covid/ Source: aatcc.org

Polygiene ViralOff promises antiviral capability with ‘lifetime of garment washability’

Polygiene is launching its newly developed formula of ViralOff with lifetime of garment washability (equivalent of 30 washes), proving performance against SARS-CoV-2 with over 99% reduction of microbes in the material within two hours. This also results in longer lasting products, which means a reduced impact on the environment. The new formula is being applied by a number of partners as we speak and is ready for high volume deliveries in January 2021. “There has been some confusion in the market as claims to washability wrongly rely on tests that are not antiviral, but rather antibacterial. We have therefore developed a treatment that provides an antiviral effect according to global test standard ISO18184:2019 (Determination of antiviral activity of textile products) and really meets the antimicrobial and antiviral claims that we make”, says Daniel Röme, Chief Technology Innovation Officer at Polygiene.

“Demand has been high from the fashion and lifestyle segments for an improved formula of Polygiene ViralOff that will have lifetime washability with a maintained high level of viral reduction. As the pandemic has evolved, there seems to be a consensus on the fact that antimicrobial materials will be the ‘new normal’ in products such as garments, bags, often-touched items, cleaning and home products and more, going forward. This regardless of the number of vaccines that are being developed, which we hope will put a stop to or slow down this global pandemic. I believe that when the world is re-opening, this feature will be highly valued by many people”, concludes Ulrika Björk, CEO Polygiene. We still believe that fewer washes are always a good thing. However, we also want to make sure that products that need to be washed, keep their effectiveness, get an extended lifetime and are not thrown away too early. Source: polygiene.com

HeiQ Viroblock wins First Place in prestigious Swiss Technology Award program

HeiQ Viroblock won the coveted Swiss Technology Award 2020 for its breakthrough antiviral textile technology, HeiQ Viroblock. This is the most notable recognition for the young company’s innovative spirit and technologies as well as its contribution to stemming the spread of the global pandemic COVID-19. The leading technology prize in Switzerland, Swiss Technology Award, yesterday announced the 2020 prizes, and among all the notable finalist innovations of the year, HeiQ was bestowed the highest honor as First Prize Winner.

Developed in record time and launched after the Swiss authorities announced the lockdown in March 2020, HeiQ Viroblock has had a major impact on the global textile industry and is being unprecedently adopted by mills around the world. HeiQ Viroblock is one of the world’s most efficient and effective antiviral/antimicrobial technologies and has been applied by more than 150 brands worldwide to over 1 billion products from face masks to apparel to home textiles to date. What exemplifies HeiQ Viroblock is its ability to turn any fabric antiviral. It’s among the first textile technologies in the world to be proven effective against the SARS-CoV-2 virus. HeiQ Viroblock consists of a combination of HeiQ’s patent-pending vesicle and silver technologies. The two mechanisms of attack result in an over 99.9% destruction of viruses in 5 minutes. HeiQ Viroblock is a unique patent-pending formulation of 72% bio-based ingredients, made with 100% cosmetic-grade materials from the International Nomenclature of Cosmetic Ingredients list. Source: heiq.com

Polygiene partners with Silvertek to incorporate antimicrobial textile treatment with FDA-approved facemask technology

Polygiene has partnered with Silvertek to provide FDA-approved facemasks with the antimicrobial textile treatment ViralOff, which is a tested and certified technology per the global standard of ISO18184:2019 against SARS-CoV-2, H3N2 and H1N1. Months prior to the pandemic, SilverTek was already developing an advanced facemask with its FDA-registered manufacturer. Unlike most masks on the market, which are being manufactured under Emergency Use Authorizations and with little thought to design, SilverTek had the benefit of time and experience to craft their proprietary FDA-listed mask for optimal comfort and breathability. For example, SilverTek discovered early in their mask development that exhalation valves were an unsafe component of mask wear due to their release of the wearer’s unfiltered exhale. For this reason, airlines, many public school districts, and entire regions such as the California Bay Area are now banning masks with valves. ”We wanted to find the best antimicrobial treatment for our NanoFit mask and evaluated numerous companies in the process”, states Silvertek President Ji-mei Ma. Further noting: “We were looking for a partner we could trust – who was environmentally friendly, wellness-conscious, and an established player in the field of antimicrobial technologies. We are glad to have selected Polygiene and have ViralOff protect our NanoFit Masks.” ”We are excited that ViralOff adds value to a FDA-listed textile mask. In addition to the high antimicrobial performance, these masks will also need less washing* and will therefore last longer, which is good for the user and the environment,: says Ulrika Björk, CEO of Polygiene. *For more information on washing habits and Covid-19, read “Survey on viruses, washing and ViralOff”. Source: polygiene.com

Data suggests cotton batting can increase the filtration efficiency of cloth facemasks

Recent FDA chief Scott Gottlieb, Ph.D., argued that he’d “rather try to get everyone in masks” and “try to get them in high-quality masks because we know it’s going to slow down the transmission.” Against this backdrop, a new study published in Risk Analysis, “Reinventing cloth masks in the face of pandemics,” by Stephen Salter, P.Eng., describes how Effective Fiber Mask Programs (EFMPs) can help communities find a balance between the economy and curbing community spread. A separate study by Stadnytskyi, et al. estimates that one minute of loud speaking generates at least 1,000 virion-containing droplets that remain airborne for more than eight minutes. If everyone uses effective masks, the benefit is compounded because each person’s mask reduces the number of particles they transmit, and also the number of particles they inhale. The new study in Risk Analysis suggests that the effectiveness of cloth masks can be improved by using a non-woven material such as cotton batting. Increasing the surface area of fibers exposed to moving air improves filtering efficiency because the smaller particles are absorbed onto the fibers. In May and June of 2020, 17 handmade cotton batting masks underwent 35 tests using commercial quantitative fit testing equipment to determine their filtering effectiveness. The results showed average filtering effectiveness of 76 to 90 percent against aerosol particles. Read the full story: https://www.sra.org/2020/10/23/new-data-on-increasing-cloth-mask-effectiveness/ Source: https://www.sra.org/

PureAir Filtration, Nobel Biomaterials partner to develop antimicrobial fiber for filtration

PureAir Filtration, a company specializing in removing corrosive gases, toxic vapors and odors, announced it has launched a strategic partnership with Noble Biomaterials, a leader in antimicrobial and conductivity solutions for soft-surface applications. The companies have developed an antimicrobial fiber called FiberShield that can be used as an added fabric layer in particulate filters to help fight microbes amid the COVID-19 pandemic. FiberShield is made of a proprietary blend of nonwoven nanofibers that are impregnated with antimicrobial Ionic+™ silver technology. The antimicrobial fabric can be used in any particulate filter and is the only one on the market to offer such flexibility to filter manufacturers. FiberShield with Ionic+ technology has been tested and proven effective by independent testing laboratories to inactivate over 99% of specific pathogens. PureAir also debuted a second product in its antimicrobial line called Microbe-sorb, an adsorbent media that utilizes a proprietary blend of compounds to activate, enhance and deliver the strong antimicrobial properties of permanganate, a material commonly used in medical practices since the early 1800s. Independent laboratory tests show Microbe-sorb inactivates over 99% of microbes on contact. Source: pureairfiltration.com

Zinc fiber technology proves 99.7% effective in combatting respiratory viruses, including influenza and human coronavirus

ION Manufacturing announced its ZnTech technology – a proprietary and patented zinc fiber matrix capable of generating microcurrent that is lethal to coronavirus and other virulent pathogens. According to ION, ZnTech has significant potential for various applications, including its use in Personal Protective Equipment (PPE) and both medical and consumer-grade electroceutical fabrics. ION Manufacturing is among the first U.S.-based companies to come to market with scientifically verified zinc-based antiviral technology. ZnTech fully destroys viral pathogens, while most currently available antiviral technology employs chemicals that only retard or repel viral particles. Market competitors often employ coatings of other metals, such as Copper and Silver, neither of which are capable of generating the microcurrent essential to kill Coronavirus. Further, Zinc is a proven safe and non-toxic element, making it most suitable for application in materials that are placed directly on the skin and over the mouth. The zinc fiber matrix interacts with exhaled moisture and oxygen, or oxygen from the skin’s surface, to generate the microcurrent. The sustainable electric field is created without wires or an external battery source and maintains its current, despite repeated washings. The antiviral properties of ZnTech facemask technology greatly decrease transmission of exhaled infectious droplets to the surrounding environment while offering protection to those who are wearing the fiber. In addition to its antiviral applications, microcurrents have many positive and well documented health benefits including increased blood flow, enhanced ATP production in the mitochondria, pain relief, collagen production and nerve stimulation. ZnTech fabric was lab tested by Integrated Pharma Services, a leading pre-clinical and clinical research organization. ZnTech™ consistently demonstrated antiviral properties against various respiratory viruses including influenza and human coronavirus with a 99.7% success rate. The antiviral efficacy testing was conducted based on ISO Standard 18184:2019. Source: ionsportswear.com

Fallon, Shawmut invest in West Bridgewater, Mass., manufacturing site, adding capacity for 180 M N95 respirators per year

The Fallon Company and Shawmut Corporation announced the creation of a new domestic manufacturing operation to produce N95 respirators. Manufacturing equipment installed in an expanded facility based in West Bridgewater, Mass. will enable end-to-end production of up to 180 million masks per year. Additionally, the operation is expected to create as many as 300 new jobs in Massachusetts. The new effort will also be supported with a $2.7M grant from the Commonwealth’s Manufacturing Emergency Response Team (MERT), a state-led initiative that has facilitated the production of more than 11 million pieces of personal protective equipment (PPE) and other critical items by manufacturers that pivoted operations to address COVID-19 at the onset of the public health crisis. This is one of 13 grants totaling $6.5 million being distributed to multiple organizations during October, or “Manufacturing Month,” to support the production of PPE in Massachusetts. “The MERT program continues to identify and support successful ‘Made in Massachusetts’ manufacturers like the Fallon Company and Shawmut Corporation, that will produce N95 masks and other PPE equipment locally, for Massachusetts front-line responders, business owners, and residents,” said Governor Charlie Baker. “We are pleased to welcome the expansion of this manufacturing facility in Massachusetts and appreciate the role these companies are playing in the Commonwealth’s fight against COVID-19.”

The operation brings together two well-established, successful family businesses to serve as one of only a handful of high-quality mask manufacturers in the U.S. The West Bridgewater facility will extend existing Shawmut manufacturing capabilities, which include medical gowns, to add polypropylene meltblown extrusion and mask conversion capabilities to create respirators, shoring up the U.S. healthcare supply chain with domestic production. The 60 tons of machinery was fast-tracked from Reifenhauser REICOFIL GmbH & Co of Germany on an expedited timeline and, last week, landed in the Port of Boston. In addition to a financial investment by Joseph Fallon, CEO of the Fallon Company, the effort will be supported by President Michael Fallon and the company’s development, legal, and construction teams. Funds will support infrastructure upgrades, utility improvements, and capital investment to Shawmut Corporation’s manufacturing facility in West Bridgewater. Widely recognized as the leader in melt-blown polypropylene production equipment, the Reifenhauser production line will enable the conversion of non-woven materials into N95 respirators in Massachusetts. Source: shawmutcorporation.com

Suominen partners with fellow Finnish companies to ensure supply and authenticity of facemasks in Finland

Finland, with no domestic facemask production at the time, had difficulties sourcing high-quality masks at the beginning of the COVID-19 pandemic. Suominen, a globally leading nonwovens producer, was one of the companies that promptly reacted to the difficult situation. In an ultra fast-tracked innovation process Suominen and its partners developed a novel nonwoven, FIBRELLA Shield, suitable for use in the manufacturing of respirators. The innovative nonwoven, developed in only a few months, has passed the European Standard EN 14683:2019 Type II requirements in terms of filtration efficiency and pressure drop.

“FIBRELLA Shield not only provides excellent protection, it is also comfortable and easy to breathe through,” said Suominen’s Category Manager Johanna Sirén. At the same time that Suominen was developing the new material, Screentec Oy – a renowned producer of medical electrodes and human-machine interfaces for demanding environments – decided to start production of high-quality face masks at its Oulu works. After an exceptionally fast installation phase, the new production line was ready by late summer. “The common aim, a fully domestic supply chain for high-quality face mask production, was a natural starting point for our cooperation with Suominen. The plan is that in the future we will mainly use Suominen’s FIBRELLA Shield in our face masks,” said Screentec’s CEO Antti Tauriainen. Suominen has been working with TrueMed Oy, an innovative Finnish start-up, already earlier. TrueMed has developed an AI and machine vision-based non-additive solution that is used to detect original and counterfeit medicines and medical products. The aim of the cooperation between the three companies is to be able to confirm the authenticity of the masks and the nonwoven used in them – in this case, FIBRELLA Shield – and thus to guarantee end-user safety. The cooperation also aims to produce important inventory information for the customer, for example, information about expiration days or how many masks that have been used. “Determining if the product is genuine or a counterfeit is done through our mobile phone app, TrueMed Scanner. We provide Suominen an identification process and mechanism that can detect the product authenticity on the fiber level of the nonwoven material. Suominen Intelligent Nonwovens utilizes TrueMed’s proprietary AI and machine vision platform. At the same time, we can read all the necessary codes and markings on the product and it’s packaging,” explained TrueMed’s CEO Jyrki Berg. “By combining the deep know-how of the three companies, we are able to offer our customers high-quality face masks with verifiable authenticity as well as the ability to follow the inventory data. In the future many of these kind of technical innovations, for example related to the end-users safety, smart supply chain data, carbon footprint information and so on, can be taken into use with Suominen Intelligent Nonwovens TM. This very fast joint development project was also funded by Business Finland research and development funding,” said Suominen’s CTO, Markku Koivisto. Source: suominen.fi

Freudenberg to add meltblown capacity in Europe

Freudenberg Performance Materials (Freudenberg) is expanding its production capacity for nonwoven media used exclusively to manufacture certified facemasks of the mouth-nose protection type pursuant to the EN14683 standard, as well as FFP1, 2 and 3 masks pursuant to the EN149 standard. The media are specially developed for and sold to the medical technology processing industry. To that end, Freudenberg is investing in the construction of a new state-of-the-art meltblown production line at the Kaiserslautern site. Commissioning of the new plant is slated for the first quarter of 2021. “As a world-leading manufacturer of technical textiles and filtration media, Freudenberg Performance Materials has deep expertise in materials for certified face masks. By expanding our production capacity in Kaiserslautern, we are making a contribution to mastering the challenges presented by COVID-19 and supplying certified type face masks as well as FFP1, FFP2 and FFP3 masks in Germany and Europe”, said the CEO of Freudenberg Performance Materials, Dr. Frank Heislitz. With the new line, Freudenberg is significantly expanding production capacity for meltblown nonwovens in Kaiserslautern. The world-leading technical textiles manufacturer produces these materials from extremely fine meltspun polypropylene microfibers that are several times thinner than a human hair. Masks made of these nonwovens can filter very small particles such as viruses thanks to the superfine structure of the material and its electrostatic charge. Source: freudenberg.com

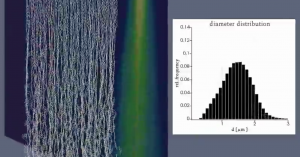

NWI’s spunbond high-efficiency filter media wins RISE Innovation Award

More than 150 professionals in product development, materials science, and new technologies convened for the 10th conference edition of RISE—Research, Innovation & Science for Engineered Fabrics, held virtually, Sept. 29-Oct. 1. The event was co-organized by INDA, the Association of the Nonwoven Fabrics Industry, and The Nonwovens Institute, and North Carolina State University. Among the program highlights was the presentation of the RISE Innovation Award, which was presented to The Nonwovens Institute at North Carolina State University for its Spunbond High-Efficiency Filter Media. The product is a completely new approach to creating filtration media with the right efficiency at low pressure drop at a throughput of 350 kg per meter per hour. The pressure drop with The Nonwovens Institute’s new filter is unmatched by any meltblown structure and doesn’t require electrostatic charging, which has been an obstacle to facemask manufacturing during the COVID-19 pandemic. The materials is also much stronger than traditional meltblown filter media, thus providing the potential for reuse after appropriate cleaning and disinfection.

NWI said it has produced 4.5 million meters of the material so far, enough to produce 100 million masks. Other nominees for the award included FemTech at MAS Holdings Pvt. Ltd. for its leakproof absorbent nursing pads and Sustainable Solutions Incorporated for its BlueCON Nonwovens initiative that produces recycled resin from hospital waste. Source: riseconf.net * International Fiber Journal is owned by INDA, Association of the Nonwoven Fabrics Industry (inda.org).

Shemesh invests $4M to develop 200PPM canister wipes technology platform

Building on decades of perfecting existing technologies pertinent to wipes production, Shemesh announced a $4 million investment in a new wipes manufacturing technology, responding to increased demand and market trends, partially set by the COVID-19 pandemic. The investment includes a new U.S. showroom and spares inventory. The all-new total solution canister wipes platform, dubbed TKS-200, is an extension of the empirically proven TKS-60 and TKS-120 models. The TKS-200 is designed to run at a consistent speed of 200ppm and a maximum speed of 220-240ppm. Prior to being available for purchase, the TKS-200 will be demonstrated to a select group of key industry players at the all-new U.S.-based Shemesh headquarters in Green Bay, Wisconsin, in the second half of 2021.

Canister wipes lines are much more sophisticated compared with lines built for other traditional market sectors, such as food & beverage or cosmetics, which Shemesh also operates. That is partially because such pharma-grade lines involve high-speed liquid filling in containers with elastic solids in them (the round nonwovens) combined with other complex technologies unique for canister wipes lines as automatically stuffing rolls (the round nonwovens) into cans in high speeds. This often happens while simultaneously dealing with alcohol-based solutions as well as in a potentially corrosive environment. Shai Shemesh, Shemesh Automation’s CEO commented, “We have been working tirelessly over the last few decades to optimize our machinery and truly perfect our total turnkey solution for the canister wipes industry. I am so proud of what we have managed to achieve with the ground-breaking TKS-200 total turnkey solution. Indeed, we know of no other company on a global scale with such deep, vertical know-how in such different technologies as Liquid Filling, Round Wipes Rolls Stuffing, Conduction Sealing, Capping, Labelling, and Case Packing – the core technologies underlying the Shemesh great value proposition catered to our customer base. As the only company in the world capable of offering a true canister wipes outfit from product feed all the way to a packed case with equipment built under just one umbrella – the edge we provide at Shemesh to our customers is immense.” Source: shemeshautomation.com

Sukano announces masterbatches for PET and PA fibers have antiviral effect

Many viruses have been shown to survive on surfaces including metal, cardboard and plastic. However, plastic items can be treated to trap and inhibit the replication of viruses. Sukano has developed Antiviral Masterbatches for PET and PA fibers that have a strong antiviral effect on the plastic parts, while also potentially helping to reduce waste and improve the sustainability credentials of the final articles produced. Sukano’s Antiviral Masterbatches work by directly integrating an antiviral additive into the polymer, using proprietary technologies. The power of this technology is that the antiviral effect not only remains stable during the usage of the product, but that it is maintained after washing. This is because the additive is consistently present on the surface of the product, without being released into the environment. Sukano conducted tests at an external laboratory specialized in microbiological testing and in accordance with ISO 18184:2019 (fabrics) and ISO 21702:2019 (plastics inject molded parts and films) to independently confirm the effectiveness of its antiviral effect on the plastic parts. The result showed that over 98 % of the Feline Coronavirus was eliminated within the first two hours. The tests were performed using the Influenza H1N1 virus and a Feline Coronavirus, which has structures and mechanisms similar to SARS-Cov-2. SUKANO Antiviral Masterbatches offer not only high performance, but also durability, as the antiviral efficacy of the fibers remains after multiple washing cycles at 40 C. This is possible without impacting the fibers’ physical properties or yellowing. Read the full announcement on SUKANO Antiviral Masterbatches: https://www.sukano.com/en/company/news/sukano-masterbatches-demonstrate-long-term-antiviral-effect Source: sukano.com

Lydall to add fine fiber meltblown line in France with capacity for 600 M respirators and 2.2 B surgical masks

Lydall, Inc., a manufacturer of value-added engineered materials and specialty filtration solutions, today announced its investment in a new production line to create fine fiber meltblown filtration media for facemasks and high-efficiency air filtration systems. This new line will be installed at Lydall’s facility in Saint-Rivalain, France, in the second quarter of 2021, substantially increasing the company’s capacity to supply this critically needed material to the European market. The investment solidifies Lydall’s position as one of the largest global suppliers of fine fiber meltblown filtration media, the crucial component of N95 respirators and the European equivalent, FFP2/FFP3, as well as surgical masks and MERV-, HEPA- and ULPA-grade air filters. Lydall will receive up to 30 percent of funding for the investment through the support of France’s Ministry of the Economy and Finance. “COVID-19 has created unprecedented global demand for face masks, upgraded air filtration systems and other products that are essential to preventing the spread of the virus. In response, governments around the world are now focused on establishing secure, reliable and sustainable domestic supply chains so they can guarantee they have access to high-quality products that are pivotal to national security and public health,” said Sara A. Greenstein, President & CEO of Lydall. “Our global footprint and 100-year heritage in creating specialty filtration solutions position Lydall to serve as a local manufacturing partner to governments around the world, now more than ever. We take our role in creating products that protect people and places from viruses such as COVID-19 incredibly seriously, and we are grateful for the support of the French government, which will allow us to ramp up production even further.” Once this additional line is operational, Lydall expects to produce enough fine fiber meltblown filtration media for 600 million FFP2/FFP3 respirators or 2.2 billion surgical masks per year. The company plans to hire additional staff to support the increase in production. Source: lydall.com

Revolution Fibres publishes paper touting electrospun nanofiber vs. meltblown

Filtration plays an important role in purifying and decontaminating two life necessities — water and air. As awareness of the related health issues has increased, the demand for protection from airborne pollution and disease has also increased. From this perspective, Revolution Fibres of Auckland, New Zealand has issued a new white paper explaining the unique and enhanced capabilities that electrospun nanofibers provide when used as an active layer in facemasks. When compared to common meltblown filters, Revolution Fibres makes the case that electrospun nanofibres provide better protection against air particles, bacteria, and viruses such COVID-19. Read the white paper: https://www.revolutionfibres.com/wp-content/uploads/2020/08/MB-vs.-NF-White-Paper.pdf Source: https://www.revolutionfibres.com/

Rockline disinfecting wipes formula receives EPA coronavirus kill claim approval

Rockline Industries announced the formula used in its hard surface disinfectant wipes (EPA registration number 6836-336) has been approved by the U.S. Environmental Protection Agency to add claim language that the formula has been proven to kill SARS-CoV-2, the coronavirus that causes COVID-19, when used according to directions. “Disinfecting wipes that kill the coronavirus that causes COVID-19 are essential to the health and safety of our communities,” said Ron Kerscher, senior vice president of sales and marketing for Rockline. Rockline is among the first private brand suppliers to receive the EPA’s approval for a coronavirus kill claim for the chemistry it uses in its disinfecting wipes products. “With this claim, retailers and consumers can have confidence that our disinfecting wipes products when used as directed will protect their homes and families,” Kerscher added. Source: http://www.rocklineind.com/

PyroTex fiber certified 99% effective against SARS-CoV-2 virus

Specialty fiber PyroTex by Hamburg, Germany-based company PyroTex Industries is reported to provide 99.57% (99% after 14 seconds) against the SARS-CoV-2 virus. This result has been confirmed by an independent, ISO-certified laboratory according to ISO 18184: 2019. The PyroTex fiber is an engineered Acrylic, which can be employed for protective masks, general protective and medical clothing as well as products for the hospitality and the private sector. The company is cooperating already several large brands to incorporate the PyroTex fiber for PPE used to support the COVID-19 response. Besides its activity against SARS-CoV-2, the flame and heat resistant PyroTex fiber also has an activity of over 99% against bacteria such as Staphylococcus Aureus, Escherichia Coli and Klebsiella Pneumoniae. All properties are permanent and non-toxic, certified according to OekoTex Standard 100, class 1. Source: http://pyro-tex.de/

Driven by wipes demand, Suominen reports record quarterly sales

Suominen achieved record high quarterly net sales and operating profit in the second quarter of 2020, increasing net sales by 18% to EUR 122.2 million. Sales volumes increased considerably, but sales prices decreased following lower raw material prices. The main driver for the volume increase was higher demand of wipes due to the COVID-19 pandemic. “We were able to respond to the increased demand by running our production efficiently despite the challenges caused by the pandemic,” said Petri Helsky, Suominen President & CEO. “Our operating profit increased significantly to EUR 12.4 million (2.7) in the second quarter mainly due to higher production and sales volumes. Also margins increased as the lower sales prices were compensated by lower raw material and other direct product costs, while fixed costs were kept well under control.” The pandemic increased sales volumes in all markets also in the second quarter. In the longer term, Suominen expects the COVID-19 pandemic may lead to a continued increase in demand for nonwovens for cleaning and disinfection products. “In June we upgraded our outlook for the year due to stronger than anticipated development in all our markets. The outlook for 2020 states that we expect that our comparable operating profit will improve significantly from 2019,” said Helsky. Source: https://www.suominen.fi/

Nonwovens Ibérica launches meltblown line

Nonwovens Ibérica announced the launch of a high-performance line for the production of meltblown, the only nonwoven suitable for the manufacture of EPI facemasks and sanitary material up to 99% bacterial filtration efficiency. The meltblown material, which has been in short supply as the global COVID-19 crisis has taken hold, is low cost and will be manufactured in large supply from the last quarter of 2020 to help support the production of facemasks and PPE needed in response to the COVID-19 pandemic. Source: https://www.encarnonwovens.com/

Two-layer polyester mask design shows 91.8% efficiency in Viral Filtration Efficacy test

Ed Goodwin, the founder and product development manager of HipSaver Inc., has always obtained scientific validation for all of his medical textile products. As such, he engaged Nelson Laboratories, to test his company’s DermaSaver Sci-Tex Mask construction. “We believed our product would be effective based on the known textile science, and now these results from Nelson Labs have proven that to be true,” says Goodwin. “Virus transmission experts agree that exposure duration and dose volume of virus particles are two key factors in overwhelming the immune system. This test result shows a dramatic reduction in the dose volume exposure.” Viral Filtration Efficacy (VFE) test showed the DermaSaver Sci-Tex Mask material construction to be an average of 91.8% effective in preventing aerosolized virus particles from penetrating through the mask. The virus particles tested are five times smaller than COVID-19 virus particles, implying that the efficacy against preventing COVID-19 virus particles from penetration could be even greater. The mask, which retails for less than $20, consists of two layers of water resistant (hydrophobic) microfiber polyester that repels airborne droplets. The brushed inside surfaces of the layers mesh together to create an additional barrier. For additional information and to view the full test report, visit: dermasaver.com

INDA publishes Meltblown Nonwoven Markets: COVID-19 Impact Analysis

With respirators and medical facemasks at the forefront of efforts to fight COVID-19, a new report from INDA, the Association of the Nonwoven Fabrics Industry, examines the market and outlook for the stand-alone meltblown process used to produce those products. The report, Meltblown Nonwoven Markets: COVID-19 Impact Analysis, presents an outlook on the meltblown required for medical facemasks and respirators in the U.S., providing insights for companies to make informed decisions during these times. The report also provides a global view of meltblown capacity.  Based on extensive research, producer surveys and interviews with industry leaders, the report is authored by Brad Kalil, INDA’s Director of Market Intelligence & Economic Insights, an industry leader on providing important information on this sector of the nonwoven industry. This report is focused on the overall market and provides an introduction to meltblown techniques, the fibers’ unique properties and end-use applications, historical capacity, and estimated U.S. and global volumes. For more information on this report: https://imisw.inda.org/store/detail.aspx?id=MELT20 Source: inda.org * International Fiber Journal is owned by INDA, Association of the Nonwoven Fabrics Industry (inda.org).

Based on extensive research, producer surveys and interviews with industry leaders, the report is authored by Brad Kalil, INDA’s Director of Market Intelligence & Economic Insights, an industry leader on providing important information on this sector of the nonwoven industry. This report is focused on the overall market and provides an introduction to meltblown techniques, the fibers’ unique properties and end-use applications, historical capacity, and estimated U.S. and global volumes. For more information on this report: https://imisw.inda.org/store/detail.aspx?id=MELT20 Source: inda.org * International Fiber Journal is owned by INDA, Association of the Nonwoven Fabrics Industry (inda.org).

Nonwovens Institute, Freudenberg PM partner to add capacity for up to 1M facemasks per month

Together with The Nonwovens Institute at NC State University, Freudenberg Performance Materials will begin production of ear loop procedure and N95 masks. The two organizations are aligning their expertise and supply chains to bring PPE to universities and healthcare workers as quickly as possible. Through this partnership, NC State is supplying Freudenberg Performance Materials with the necessary roll goods needed for production while Freudenberg provides the textile manufacturing expertise and work force needed to install, operate and maintain the four new production lines. “As the leader in the development of the next generation of nonwovens, we knew we could step in and help fill this critical need. By partnering with Freudenberg, we will ensure the reliable completion of millions of protective face coverings to battle the coronavirus using NWI’s novel filter media”, says Behnam Pourdeyhimi, Executive Director of The Nonwovens Institute. Once fully operational, the site will be able to produce more than one million masks a month. In addition to the facemask lines provided by NC State, Freudenberg is also in the process of installing six additional production lines to manufacture surgical and N95 masks. Not only will the lines help provide essential face coverings, but the addition of the lines has enabled Freudenberg to add 50 new positions within the company to operate the lines. Source: freudenberg-pm.com & thenonwovensinstitute.com

IFAI Expo to be all-virtual in 2020

Given the continuing uncertainty with the spread of the COVID-19 pandemic and the importance of the health and safety of the entire textile community, IFAI has made the difficult, yet unavoidable decision to transition IFAI Expo 2020, set for November 3-6, 2020, in Indianapolis, Ind., to an online only virtual event. IFAI Virtual Expo will take place over several days in early November 2020 in a robust platform designed to provide many exciting opportunities for attendees, exhibitors and sponsors to discover, network and help grow their businesses. Going virtual allows attendees — both domestic and international — to experience IFAI Expo in a new way. Attendees will explore the knowledge-packed educational sessions from the comfort of their home or office. Textile professionals from anywhere in the world can discover new products, chat, network and meet with exhibitors, communicate with colleagues and learn from world-class educators and presenters. The decision to cancel the live event was not easy. IFAI considered the impending potential cost exposure of exhibitors and attendees, and concerns for safety, as well as travel difficulties inhibiting attendance, and determined this was our best option. Source: ifai.com

Bolger & O’Hearn donates hand sanitizer to support COVID-19 response