The Earth Held Center Stage in Dornbirn GFC Discussions

The 63rd Dornbirn Global Fiber Congress (GFC) has been a cornerstone of the industry for more than 60 years, providing a unique forum for industry professionals, innovators and researchers to exchange ideas and drive the future of fibers and textiles.

In an era of disruption and political and economic uncertainty, the GFC held in the Austrian city of Dornbirn, offered some encouragement and hope for the international fiber and textile supply chain.

The event attracted more than 500 visitors from 32 companies, including representatives from around 270 companies, organizations and institutions, from fiber producers through to retail brands, which “shows the circularity of the industry,” said Robert van de Kerkhoff, president of the Austrian Fibers Institute, opening the conference.

With more than 125 lectures across three days, the opening sessions introduced such topics as energy innovations, industry drivers, European Union (EU) textile strategy and tackling greenwashing, while much of the congress emphasized fiber innovations, the circular economy, recycling and sustainability. New focus areas for 2024 included energy solutions and a cross-industry session with the paper and packaging industry.

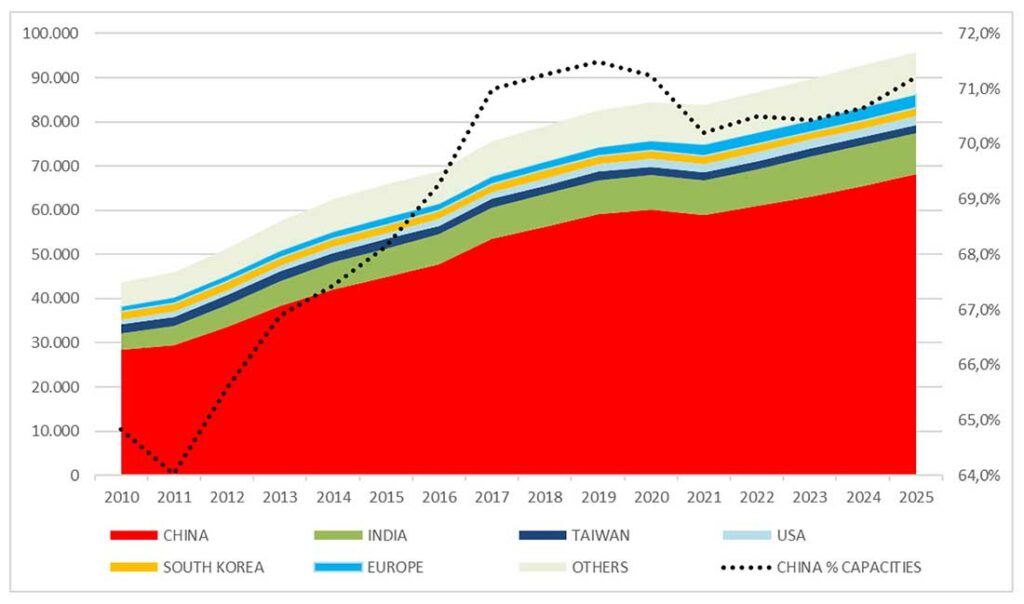

China’s Polyester Capacities

In 2023, polyester continued to dominate global man-made fiber production of 81.5 million tonnes, with a market share of 75%, followed by cellulosics with 9%, polyamide 8%, polypropylene 5%, acrylic 2% and other synthetic fibers 2%.

In particular, China’s polyester fiber production capacities continue to increase, with capacity utilization returning to pre-pandemic levels. Frédéric van Houte, director-general of CIRFS, the European Man-Made Fibres Association, reminded the audience that, despite China’s dominance in man-made fibers with a 70% market share, Europe remains the third largest producer as a diverse, specialized supplier with 3.2 million tonnes in 2023.

The European man-made fiber industry is facing numerous challenges such as sluggish demand and high costs, especially for energy and raw materials, as well as trade distortions and a “tsunami” of new environmental legislation, particularly on circularity.

Meanwhile, at the consumer level, fiber content – and the environment – is still relatively low on the list of purchasing criteria, below comfort, fit, overall quality, price, color and durability.

The world is, at present, more unsettled, and tensions and conflicts are on the rise, which is affecting business. “But even in these difficult times there are a lot of opportunities,” said van Houte. “Our industry is innovative, sustainable and constantly adapting to change. Man-made fibers are essential and indispensable in a wide number of important applications in everyday life where they cannot be substituted.”

Slowdown in Garment Production Growth

Giuseppe Gherzi of the Switzerland-based management consultancy Gherzi Textile, noted that there is little new textile production being planned, apart from some factories in Vietnam, Africa and Central America.

Analyzing the textile added-value chain, he expects a slowdown in garment production growth in 2026 when total global fiber consumption will amount to 125 million tonnes. “And we do not see polyester disappearing at all,” Gherzi said.

In terms of final consumption, the market in 2026 is predicted to exceed US$2.1 trillion, comprising 52 million tonnes of garments worth US$1.6 trillion, 22 million tonnes of home textiles worth US$300 billion and 23 million tonnes of technical textiles worth US$230 billion (including nonwovens worth US$40 billion and composites worth US$43 billion).

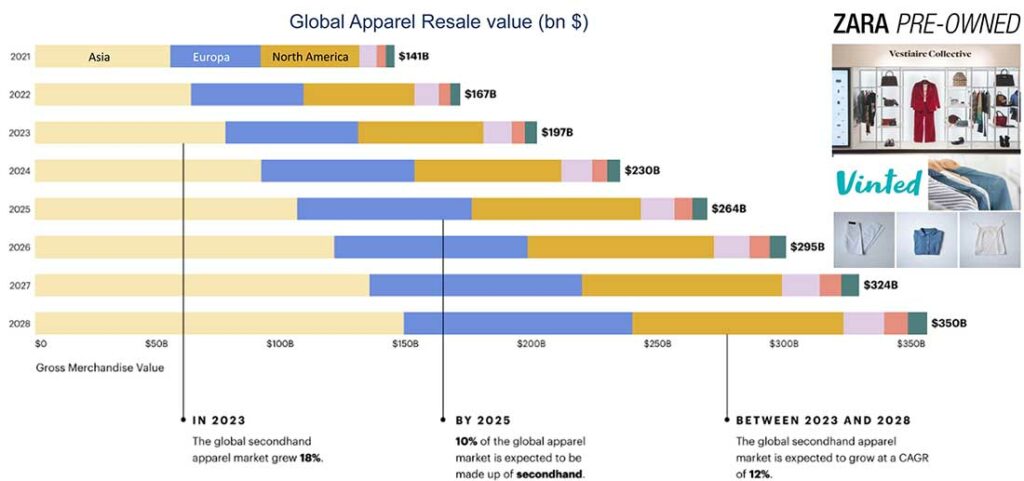

While garment consumption growth will continue to increase, Gherzi is forecasting a slowdown in garment production growth, partly due to the flourishing resale market. In addition, major disruptions that will affect the textile industry include new legislation, changes from retailers and consumers, collecting and recycling issues, and new technologies.

In an insightful presentation, Gherzi identified 34 major trends impacting the industry, all of which will affect the textile added-value chain, under the broad headings of resources, design, production,

retail, consumption, end of life, and systems thinking and regulation.

Textile collectors, sorters and recyclers are also coming into the value chain, backed by finance and with good access to brands and retailers, who themselves are mostly stagnating and under pressure from ultra-fast fashion, which young consumer are now buying in preference to fast fashion, said Gherzi.

Also coming into the market are new, highly disruptive fiber materials. For example, US-based cellular agriculture start-up Galy, a developer of laboratory-grown cotton founded in 2019, recently secured US$33 million in funding to accelerate the development of cotton and other plant-cell based products. Investors include Indorama Ventures, Inditex and H&M, as well as OpenAI’s Sam Altman.

Meanwhile, the resale market is growing dramatically and is perhaps now bigger than fast fashion. In 2023, fast fashion suppliers, such as Zara/Inditex, H&M, Uniqlo/Fast Retailing, Gap, Mango, Esprit, Primark, New Look and River Island, had estimated sales of US$130 billion, while ultra-fast fashion producers, such as Shein, Temu, Fashion Nova, Boohoo, Pretty Little Thing and Cider, had sales that have grown quickly to an estimated US$50 billion.

In the next growth phase, ultra-fast fashion will be competing with the apparel resale/second-hand market, with players such as Zara Pre-owned and Vinted, which is forecast to rise from US$200 billion in 2023 to US$350 billion in 2028, divided approximately one-third to each of North America, Europe and Asia, according to figures from ThredUp.

The Truth Behind Greenwashing

In another thought-provoking presentation, Dr. Dimitri Deheyn, a marine biologist at the Scripps Institution of Oceanography, University of California San Diego, USA, noted that in 2023 most lectures at the Dornbirn GFC indicated that businesses are sustainable and circular. However, the reality on the ground is different, he said, with “tonnes and tonnes of textile waste on the beach and microfibers in the oceans – and even everywhere else.”

Deheyn challenged the fiber industry to employ critical thinking, which is imperative when providing any level of information on a product or process, to communicate a clear message to a target audience and to avoid greenwashing, unconscious or otherwise. “As a responsible community of experts, we should set the best standards communicating with transparency about textile products,” he urged the audience.

Energy Solutions

The presentations on the topic of “energy solutions” during the three-day congress started with a plenary lecture on the opening day by Rudolf Zauner, an expert in renewable energies from Verbund, Austria, who started the discussion with a keynote paper on energy transition and its implications for industry and energy innovations.

He highlighted the increasing emphasis on decarbonization and the pivotal role that renewable energy sources play in pushing for systemic solutions and presented innovative energy solutions, outlining what can be achieved when the worlds of industry, energy suppliers and start-ups meet and how the competitiveness of industry can be maintained.

Industry Awards

During the congress opening, Uday Gill, former chief strategy officer at Indorama Ventures, received a Lifetime Achievement Award for his contribution to the man-made fiber and textile industries. His address gave valuable lessons for companies to succeed in uncertain times, stressing the need to continue the learning process, particularly at conferences such as Dornbirn.

Meanwhile, the 2024 Paul Schlack Prize for young researchers in Europe was awarded to Dr. Lars Bostan of the Faserinstitut Bremen, Germany, for his work at Bremen University on the development of melt-spun islands-in-the-sea lignin precursor yarns for carbon fiber production.

Support for Young Innovators

This year, 25 start-ups were invited to showcase their latest developments during the 4th Innovation Days, which is a whole conference in itself, offering participants a glimpse into the future of fiber and textile technologies.

Additionally, an exhibition space for 22 young exhibitors provided delegates with the opportunity to explore their latest developments, which included designer proteins, melt-spun marine-degradable fibers, polyhydroxyalkylanoates, silica nanorods, industrial hemp and protein-based biopolymers for hollow fibers and filaments.

Compostable Polyester Fiber

A highlight was presented by Intimiti Australia, which claims to have created the world’s first certified compostable polyester fiber: Celys is 95.4% compostable in 179 days under industrial composting conditions.

A third chemical monomer is introduced into the molecular structure of the Celys fiber to participate in the polymerization process, said Helen Weng, global sales director.

As a result, the company has been able to successfully insert easy hydrolysable, easy-to-break-down ester linkages into the polymer backbone, which facilitates hydrolyzation, thus greatly accelerating the bioderadation rate.

“This is why Celys fibers can be compostable while polyethylene terephthalate cannot,” said Weng. “After the biodegradation takes place, all that is left behind is carbon dioxide, water and biomass.”

Resulting fabric properties with Celys include a soft cotton-like touch, low pilling, hydrophilicity, low-temperature dyeing, natural wicking and breathability, and quick drying. Potential applications include denim, sportswear, underwear and outerwear, as well as home textiles and footwear.

Product Heating Using Copper

Dr. Murielle Schreck, chief executive officer and co-founder of Swiss start-up qCella, outlined product heating technology using copper inside cellulose hybrid fibers as an alternative to conventional heating wires. The company, a spin-off from ETH Zürich, has developed energy-efficient heating mats for applications such as heated car seats, clothing and heat wraps.

The mats have the required electrical resistance across the entire structure so that they heat homogeneously when connected to a power source, such as a battery. The thinness and smoothness of the heating mats allow for more energy-efficient heating by eliminating the need for a heat-losing upholstery layer between the mat and the human body.

Further, the heating mats can be cut into any shape and size and are easily and cost-effectively integrated into the final heated product, said Schreck.

Beyond heating applications, the qCella material can also be used for electromagnetic shielding and conductive polymers. A future development is the impregnation of silver inside cellulose hybrid fibers.

Bleach and Dye Biotechnology Solution

Graham Stewart of Fibre52, USA, outlined a patented biotechnology solution to prepare, bleach and dye cotton-rich fabrics. Applying bio-friendly products instead of traditionally harsh chemicals, such as caustic soda, the Fibre52 process works with existing machinery and uses less time, water and electricity, and can also lower carbon emissions.

The ingredients allow for the process to use lower temperatures and fewer bath drops. “Not only does it result in a more sustainable, durable and comfortable cotton, but it also naturally has performance characteristics often seen in synthetics,” said Stewart.

Tests show that the Fibre52 process is consistently repeatable, reliable and good on all shades, he added. In addition, mills do not have to drastically change their dyes or dye recipes to achieve the

same results.

Global Network Generator

Since its inception in 1962, the Dornbirn GFC has emerged as a global network generator, providing invaluable knowledge-sharing opportunities across the fiber and textile value chains.

“The congress will continue to push the boundaries of innovation and provide a platform for exchange, innovation and networking to support the textile industry’s transformation toward closing the loop in fibers and greening value chains,” said van de Kerkhoff.

The event was also available “online on demand” for three weeks after the conference, offering registered delegates presentations as both video and downloadable content.

But despite the creditable attendance in the post-pandemic landscape, many delegates from Asia were absent, especially from China, the world’s largest fiber producer. And with little discussion of natural fibers, the congress is still dominated by the man-made fibers sector,

especially from the European perspective.

Management Changes

Friedrich (Fritz) Weninger has finally stepped down after nine years as managing director of the Austrian Fibers Institute, organizer of the GFC. Andreas Dorner has also stepped down as co-managing director to take up a new position as managing director of Re&Up Textile Recycling Technology.

They have been replaced by Matthias Gluth, who has 25 years of experience in the fiber and chemical industry, having held leadership positions at Lurgi Zimmer, DuPont, Clariant and Lenzing.

Next Event

The 64th Dornbirn GFC will take place from September 10–12, 2025, followed by the next Asian GFC, to be held in partnership with Techtextil India and Messe Frankfurt in Mumbai, India, in November 2025. An event in Bangkok, Thailand, is also planned for April 2026.