Technologies

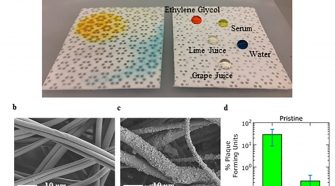

Student Spotlight: Reusable textiles for liquid and virus repellency

Anthony John Galante is pursuing a Ph.D. in Industrial Engineering at the University of Pittsburgh, where he is conducting research on microbe repellent surfaces at the Lab for Advanced Materials …

Enhancements in low-temperature dyeable polyester filament yarn

Polyester fibers and yarns dominate the global synthetic fiber industry and are forecast to increase their market share in the future. This is due to polyester’s unique, inherent properties such …

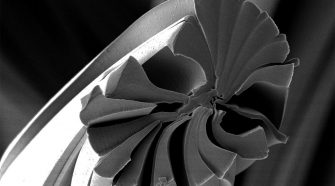

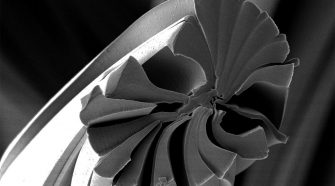

Bicomponent fiber – get more than 2x

A biocomponent fiber, or bico, is a fiber that combines two separate polymers into a single filament. The term conjugate fiber is also used as a synonym. The process …

Transforming textiles with cast foam

Recently, TSG developed technology allowing for the generation and application of cast foam onto the widest variety of textiles in the industry. This development is really a convergence of several …

How hot-air bonding production parameters affect bi-component fiber nonwovens

Hot-air nonwoven is three-dimensional porous fabric with fusible fiber as the main material. With these features, it is widely used in medical care and hygiene (e.g. sanitary towel, tampons, etc.), …