Raw Materials

Beaulieu Fibres International highlights investments and technology innovator commitment

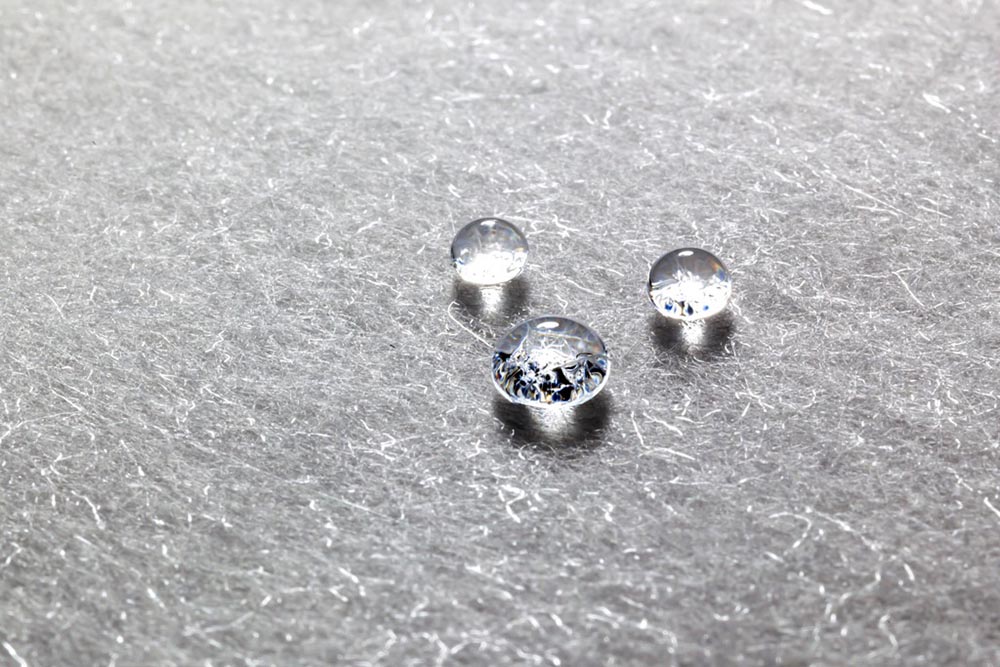

Beaulieu Fibres International is continuing to strengthen its position as a global supplier of polyolefin fibers. Large investments in fiber production is an important driver ensuring it can meet future challenges and customers’ needs. Since the acquisition of Meraklon four years ago, the product portfolio has been broadened significantly to better serve market needs. Several investments were made to offer trilobal shaped mono polypropylene (Mono PP) fibers and bicomponent (BICO) fiber with a PP core and polyethylene (PE) sheath.

NILIT continues global launch of Sensil® premium nylon 6.6 at Intertextile Shanghai, 11-13 October, Hall 5.2 Stand 5.2 C-95

Migdal Haemek, Israel – NILIT, a leading global manufacturer and marketer of nylon textile fibers, continues to introduce Sensil®, its new premium Nylon 6.6 brand, to the apparel industry at Intertextile …

Calls for restructuring of the global fiber industry

By Geoff Fisher, European Editor

Over the past four decades the German/European manmade fiber industry has weathered many critical situations and has managed to survive. A key reason has been its ability to develop innovation and change management strategies.

Fiber producers are affected by global megatrends such as technological breakthroughs and demographic shifts on the one hand, and increasing protectionism affecting business worldwide on the other.

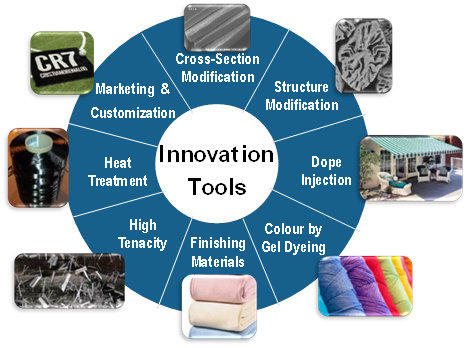

Acrylic fiber – new life through creativity

Seventy-five years have passed since the invention of acrylic fiber by DuPont scientists in 1941. Described as a “remarkable” fiber that is not damaged by sunlight, this fiber was claimed to have lasting resistance to mildew, high temperatures and even sulfuric acid. Many other features have since been discovered that have increased the product interest and range of applications. Several innovation tools have been used to reinvent the product and increase its lifetime, ensuring its suitability for textiles and technical applications, as well as for carbon fiber production.

Manmade fiber industry expects steady growth

Attendees at the 22nd China International Manmade Fiber Conference (CIMFC) held in Fuzhou in September.

By Jason Chen, China Correspondent

At the 22nd China International Manmade Fiber Conference (CIMFC), held at the beginning of September in Fuzhou (Fujian province), China, experts and executives spoke about advanced materials, fashion trends, testing methods and standards, and investment trends within the industry.