Bio-Based Fiber

The fate of plastics and bio-based fibers

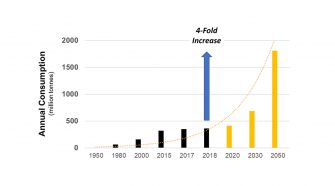

The nonwovens industry supplies a diverse range of products to multiple markets. Many of these products, especially those that target consumers, such as hygiene products and wipes, are largely designed …

Rice and wood – building for the future on Japan’s natural resources and fiber legacy

Many of Japan’s major corporations began as fiber manufacturers, and their expansion has been decades long, typically involving diversification into other fields such as chemicals, plastics, pharmaceuticals, life sciences, real …

A strange brew – genetically engineered polymeric fibers

Over the past century, man has truly harnessed the power of artificial polymer materials; polymeric fiber materials have allowed for applications not possible with the use of natural fibers. Driven …

Bio-based fibers with improved properties for clothing applications

Most fabrics currently available on the market are made of natural fibers, such as cotton and wool, and polyester (PES) blends. With the aim of finding a more sustainable material to produce clothing, polylactic …