Technical Textiles

Spaced out in Frankfurt at biggest ever Techtextil

By Geoff Fisher, European Editor

Under a generally positive global economic climate, the latest Techtextil held in May in Frankfurt am Main, Germany, was another hugely successful event with record numbers of visitors and exhibitors. The international trade fair for technical textiles and nonwoven, which is held every two years in conjunction with Texprocess, the trade fair for the processing of textile and flexible materials, together attracted more than 47,500 visitors – an increase of 14% over the previous events in 2015 – from 114 countries.

Techtextil North America exhibit reflects healthy fiber industry

By John McCurry

The 13th edition of Techtextil North America (TTNA), held May 3-5 at Atlanta’s World Congress Center, achieved positive results by most accounts. This year’s show housed 351 exhibitors and drew more than 7,000 attendees. Many exhibitors were pleased with the event’s traffic while others reported their objective was to let the world know they are open for business. As it did two years ago, TTNA shared an exhibit hall with Texprocess Americas and the JEC Composites show.

Technical textiles market forecast to grow rapidly

By Geoff Fisher, European Editor

Sportswear that can measure heart rate and other performance metrics, and jackets that can control a smartphone are at the cutting edge of the burgeoning wearables sector. With a focus on technology, design and function, this trend is placing new demands on fabric makers developing e-textiles and other smart garments.

But the growing field of high-tech textiles does not solely involve integrating electronics into yarns and fabrics to produce trendy apparel; technical textiles are offering solutions in a wide range of end-uses using innovative yarns, fabric constructions and finishes.

Plasma modification of technical textiles

By Martin McCoustra and Robert Mather, Heriot-Watt University and Power Textiles Ltd.

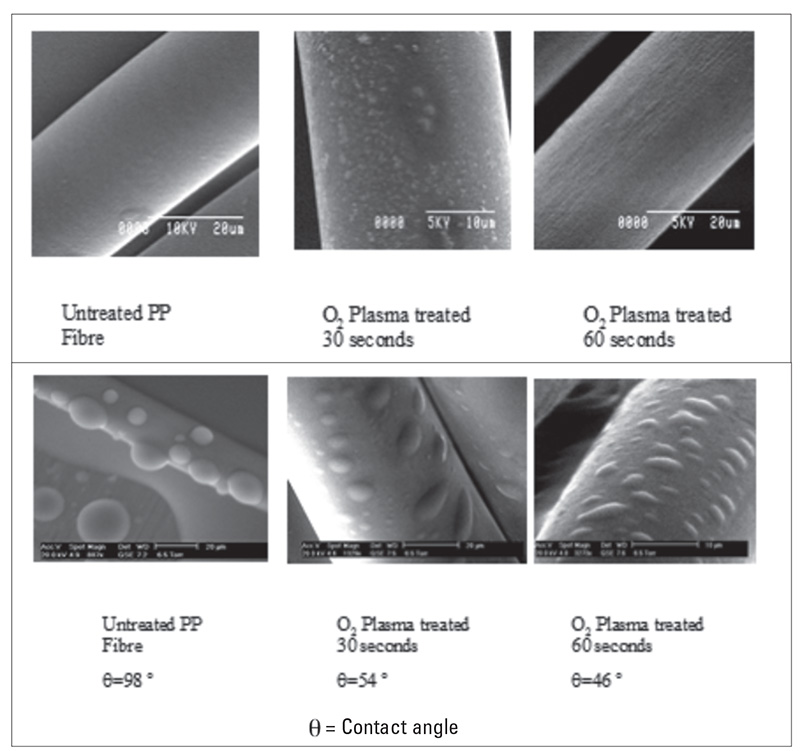

Gas plasma treatment technology will be a game changer for processing textiles, and in particular technical textiles. The treatments adapt their surface properties without affecting any of their bulk properties. The plasma technique provides a clean, dry approach that consumes far less energy than do traditional wet treatments, the level of effluent is greatly reduced and, crucially, equipment on an industrial scale is commercially available1.

Techtextil sets exhibitor and visitor records; drives innovation trends

A rail strike in Germany did little to dampen the enthusiasm for visitors to Techtextil last month, when around 42,000 from 116 countries made their way to Frankfurt am Main. …