Materials

Private label convertor invests in sustainable technology

EcoWipes, a manufacturer and converter of private label products for the wetlaid hydroentangled nonwoven segment, has ordered its third nonwovens production line. Located north of Warsaw, Poland, the firm was established in 2009 and has a strong focus on innovation and sustainability, and constantly monitors local and global market trends.

In view of the rising consumer interest in biodegradable materials, EcoWipes opted for Trützschler Nonwovens and Voith to supply the new production line.

Fine-denier polyester nonwovens for filtration

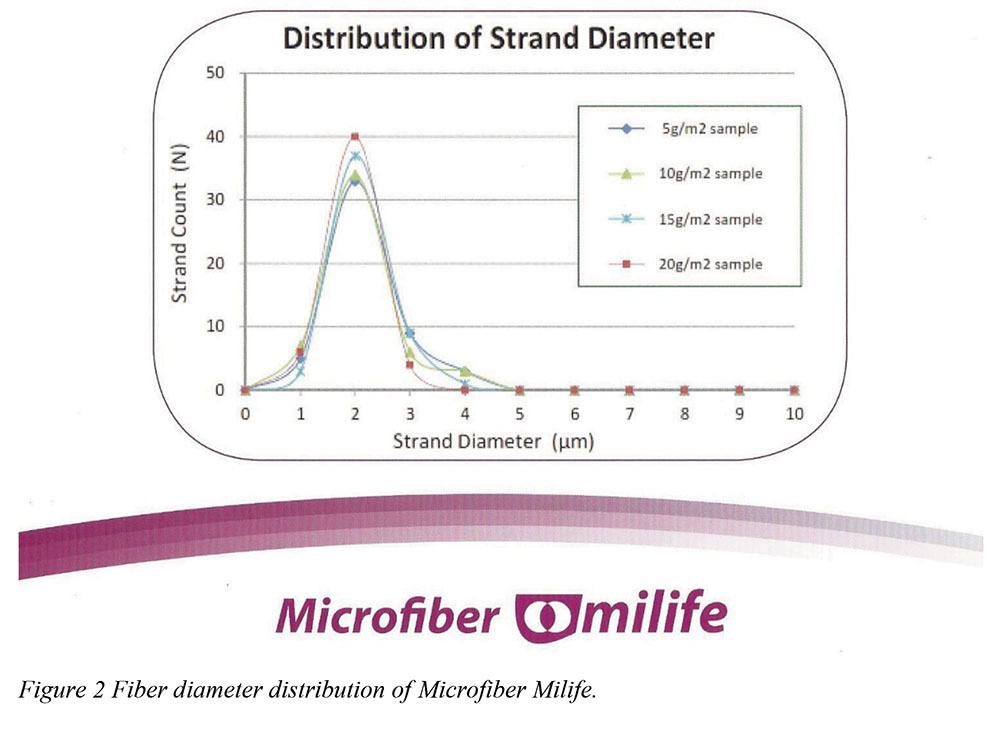

JX Nippon ANCI, headquartered in Kennesaw, Georgia, USA, with manufacturing in Roanoke, Alabama, and Dalton, Georgia, has launched the Milife range of fine-denier polyester nonwovens for filtration applications. Milife uses a proprietary technology that results in continuous fibers like spunbond, but with a process that results in unique appearance and properties.

New report: “Spunbonded and Spunmelt Nonwoven Polypropylene World Capacities”

“Spunbonded and Spunmelt Nonwoven Polypropylene World Capacities, Supply/Demand, Manufacturing Economics and Profitability 2012, 2017 – 2022” Price Hanna Consultants LLC, a management consulting firm whose principals have specialized in the …

INDA rebrands “Nonwovens” to “Engineered Material Solutions”

New Tagline Better Defines the Dynamic Technology-Based Industry to Attract Young Talent INDA has launched a rebranding initiative to strengthen recognition of the nonwovens industry as a stand-alone, vibrant, attractive sector …

IVL to acquire DuraFiber Technologies to boost automotive and industrial sectors

Global chemical producer Indorama Ventures (IVL) has entered into an agreement to acquire DuraFiber Technologies DFT México Operations, a producer of durable technical textiles for industrial, tire reinforcement and specialty …