Materials

Top technologies for the processing of high-performance fibers

The textile machinery branch of Germany’s VDMA, the Frankfurt-headquartered mechanical engineering industry association, held a series of webinars showcasing the technologies of some 30 of its members between June and …

Bally Ribbon Mills brings smart textiles to commercialization

Bally Ribbon Mills (BRM), a leader in the design, development, and manufacture of highly specialized engineered woven fabrics, announces it is bringing to commercialization a variety of smart textile products …

Creating a more breathable, reusable N95 mask

NatureWorks, Nonwovens Institute collaboration produces an innovative new filter media As the world faces a critical shortage of personal protective equipment (PPE) for medical workers confronting the COVID-19 pandemic, a …

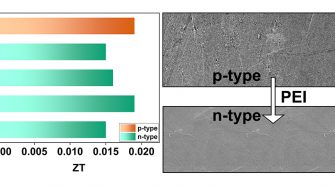

Student Spotlight: The hot and cold of smart fabrics

Kony Chatterjee is a doctoral candidate in the Fiber and Polymer Science program at Wilson College of Textile’s Department of Textile Engineering, Chemistry and Science at North Carolina State University. …

Web-based composites – a new class of materials with high potential for recycled carbon fibers

Web-based composites are nonwoven-based composite materials that meet the demand for sustainability and light weight. This new class of materials offers the possibility of processing recycled composite waste and thus …