Nonwoven

INDA’s Rousse Considers State of the Nonwovens Industry in Buildup to IDEA19

IDEA19 will bring thousands of thought leaders in the nonwovens industry together for four days of training, exhibits and special programs, March 25-28, in Miami Beach, Fla. (Image courtesy of INDA.)

Q: IDEA is returning to Miami Beach this year. How do you feel about that and what are some of the key features of IDEA19 that attendees should not miss?

A: We are delighted to be going back to Miami Beach and the Miami Beach Convention Center. This venue is ideally suited for our event, as the floor size and newly renovated meeting rooms are just what our exhibitors are looking for. We occupy the entire site.

Lenzing announces leadership changes

Jürgen Eizinger will succeed Wolfgang Plasser as Vice President of Global Business Management Nonwovens from March 1, 2019 onwards. Wolfgang Plasser will assume new role as lead of Global Quality …

INDA purchases leading filtration and fiber industry publications: International Filtration News and International Fiber Journal

INDA, the Association of the Nonwoven Fabrics Industry, today announced the acquisition of two leading industry publications: International Filtration News and International Fiber Journal. The association purchased the publications from International Media …

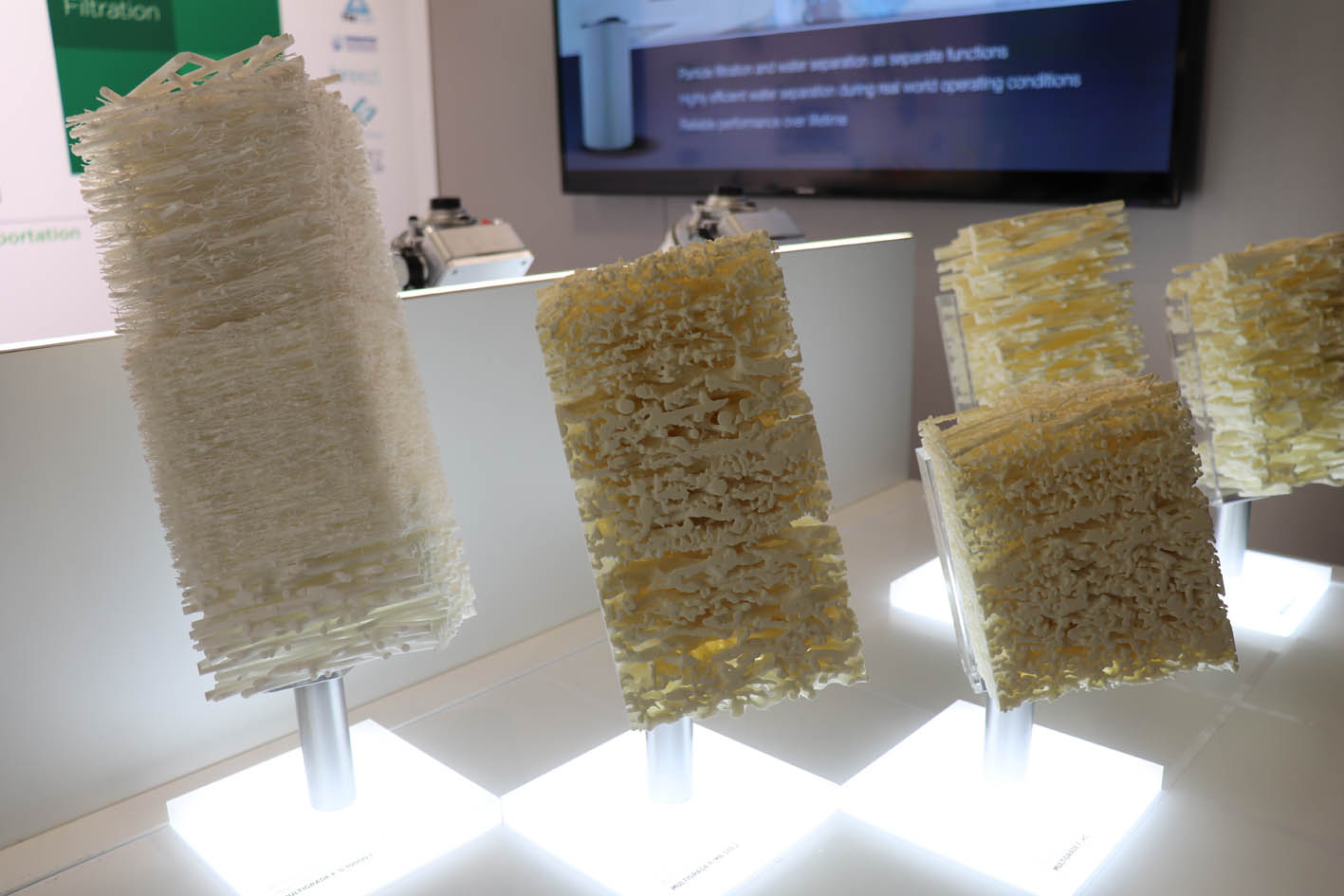

New industries will secure continuous growth for nonwoven filter media

By Adrian Wilson, International Correspondent

Mega-trends are ensuring the continued expansion of the filtration industry, which is estimated by the American Filtration Society (AFS) to have an annual value of around $80 billion globally. The demands for purer air and cleaner water are the biggest, and both are the subject of ever-more stringent legislation.

Nonwoven filter media delivers value throughout filter lifecycle

By Juliana Khouri, Category Marketing Manager, Kimberly-Clark Professional Filtration

As the general public becomes more aware of the health and productivity advantages of good indoor air quality (IAQ) and the environmental sustainability and cost advantages of reduced energy consumption, air filter manufacturers are taking a closer look at the filter media they use.