Nonwoven

Fibers for nonwovens – in pursuit of viable alternatives

As has been previously noted in International Fiber Journal, the nonwovens industry needs alternatives to synthetic fibers, and specific sectors need them fast (see “Legislation poised to boost demand for …

How hot-air bonding production parameters affect bi-component fiber nonwovens

Hot-air nonwoven is three-dimensional porous fabric with fusible fiber as the main material. With these features, it is widely used in medical care and hygiene (e.g. sanitary towel, tampons, etc.), …

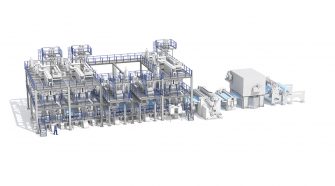

Reifenhäuser’s R5 marks significant advance for spunbond, meltblown process efficiency

Recently, Reicofil introduced the latest generation R5 technology, providing five major benefits in output, quality, efficiency and uptime all centered around intelligence to maximize productivity, reliability and efficiency. The Reifenhäuser …

Worldwide staple fiber-based nonwoven consumption

Staple fiber represents nearly two-thirds (59%) of the resin and staple fiber used in the nonwovens industry. The consumption of staple fibers by drylaid, wetlaid, and airlaid short-fiber nonwovens production …

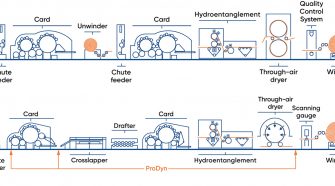

Process Profile: Hydroentanglement bonding process for nonwovens

Hydroentanglement (sometimes referred to as spunlacing) is a bonding process used in the manufacture of nonwoven materials. It can be employed with either carded, wetlaid webbed, or drylaid webbed fibers. …