Composite

Overcoming Challenges of Industrial Bio-Composites

Testing New Manufacturing Processes for Composites Reinforced with Natural Fibers and Biological Resins The utilization of biological materials as reinforcement in the development of industrial composites emerges as a potential, …

BIOCarbon Fiber Takes Flight

Exploring New Entry and Exit Routes for Carbon Fiber Composites Despite its currently unmatchable benefits in enabling the production of lightweight parts that are exceptionally strong and have been critical …

China’s Fast-Growing Carbon Fiber Demand

Expanding Sustainability Includes Exploring Fiber Advancements in China for the Growth of Their Green Economy At the 29th China International Manmade Fiber Conference (CIMFC), September 26-27 in Jilin City, Jilin …

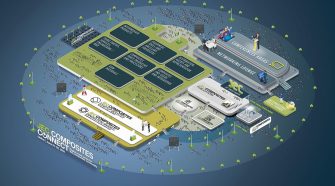

JEC Group goes all-virtual with JEC Connect digital event

JEC Group, the world’s leading company dedicated to promoting composite materials, has adapted its annual JEC World event as an all-new digital platform called JEC Composites Connect. The virtual event, …

Top technologies for the processing of high-performance fibers

The textile machinery branch of Germany’s VDMA, the Frankfurt-headquartered mechanical engineering industry association, held a series of webinars showcasing the technologies of some 30 of its members between June and …