Sustainability

Textiles – progress in the making

It was very apparent at this year’s combined Techtextil, Texprocess and one-time-only Heimtextil Summer Special shows which were held in Frankfurt, Germany, from June 21-24, that European legislation is currently …

A net zero vision

A hail of silver bullets required – getting plastics to net zero What if all plastics, including synthetic fibers and nonwovens, could become net zero in greenhouse gas emissions (GHGs) …

The future of textile recycling

Recycling concepts of textiles and nonwovens continue to evolve. Textiles lead the way as textile recycling is one of the oldest and most established recycling industries in the world. Fibers …

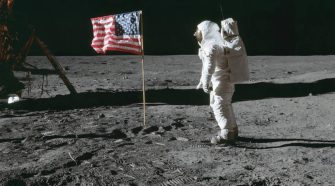

Shooting for the moon with new nylons in 2022

There can be no more potent a symbol of the golden age of synthetic fibers than the planting of the U.S. flag on the moon by Buzz Aldrin on July …

Lenzing sees sustainability at the heart of its business strategy

Lenzing Group, a global company headquartered in Austria, is a leading player in the world of cellulose fibers. For its partners in the textile and nonwovens industries, Lenzing’s cellulose fibers …