End-Use Markets

WORLD OF WIPES® From Inception to Perfection

Focus on Materials & Collaboration for a Sustainable Future This year, the World of Wipes® lands at the Hyatt Regency in Minneapolis Minnesota on June 17-20 with a theme of …

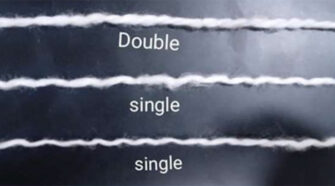

PP Yarn for Filtration

DREF spun polypropylene yarns are largely consumed in the manufacture of wound filters supplied to the domestic filtration sector. Suitability of alternative spinning systems can be explored to establish their …

Startups at Center Stage

Textile Innovation Emerges from Industry Gatherings as the Stars of the Show In the past year, startup companies have been gaining valuable exposure at textile industry exhibitions and conferences, showcasing …

Flush Right

New California Wipes Study Proves Flushable Wipes Work as Described; There is Yet Much Work to Do on Consumer Education for the Wipes Marketplace In the fall of 2023, INDA, …

Lenzing Takes Center Stage at Heimtextil, Bringing Latest Fiber Innovations to Global Brands and Customers

The environment has been the center of various discussions in recent years. People are more concerned about their ecological footprint and are seeking products produced with resource-efficient processes. Brands and …