End-Use Markets

Tailored non-crimp-fiber technology for a cost saving and highly efficient manufacturing of automotive components

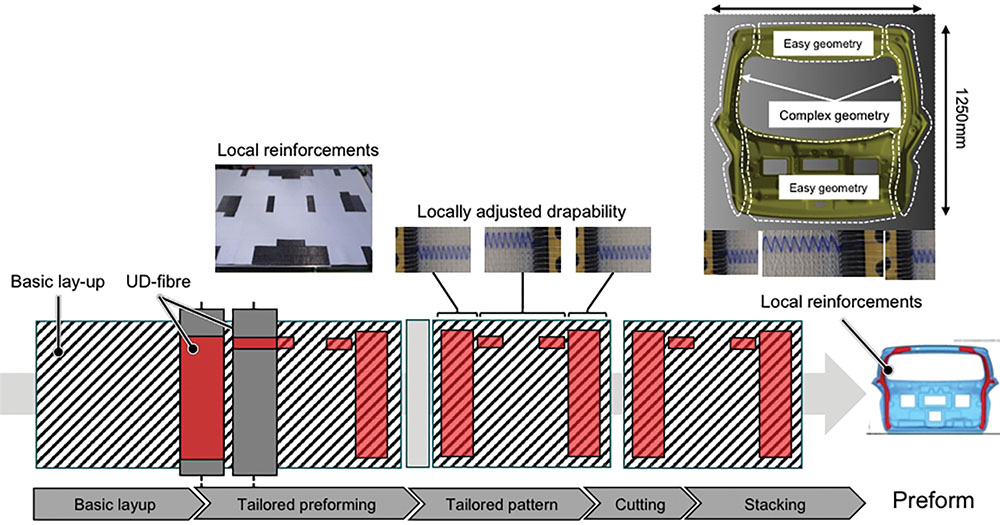

The automotive tailgate part is one of the most complex components of a car. It has to be resistant against impact forces and at the same time it needs to be stiff. To meet these requirements the conventional tailgate consists of several metal components, the outer and inner part and several additional reinforcements parts. In order to address light weight design, the substitution of metal components with composites is considered.

SILVADUR™ antimicrobials from Dow Microbial Control earns certification from global textile industry safety standard organization, Bluesign®

Dow Microbial Control, a global business unit of DowDuPont Specialty Products Division, announced in August that its patented antimicrobial technology for textiles and apparel – SILVADUR™ Antimicrobials – has been certified …

Huntsman Textile Effects introduces HIGH IQ® Sun Protect

Performance assurance program for textiles with built-in sun protection Huntsman Textile Effects has extended the HIGH IQ® performance assurance scheme to help mills, brands and retailers meet consumer demand for …

Enhanced occupational safety drives protective textiles market

By Geoff Fisher, European Editor

The second half of the 20th century saw a dramatic increase in the need for personal protection. The rise of health and safety requirements in the workplace has required the use of protective apparel for workers in many industries, while the threat of chemical and biological terrorist attacks, as well as natural pandemics, have become key political issues.

REPEL provides PFC-free water repellency versatility for every A&E sewing thread

American & Efird (A&E), a global leader in industrial sewing thread manufacturing, announced the official launch of REPEL, an advanced, PFC-FREE, water repellency enhancement. REPEL is an additional feature customers …