Geosynthetics & Agriculture

Geo-Synthetics: significance and application in everyday life

By Ken Norberg, Editor

Applications, fiber quality and stabilization determine the quality of nonwovens. The Oerlikon Manmade Fibers segment, a proven expert in polymer processing, spinning and texturing, also beneficially deploys its many years of expertise for its nonwovens (airlaid, meltblown and spunbond) and staple fiber technology.

The group’s Neumünster, Germany-based nonwoven business unit is therefore able to offer solutions for processes and systems for manufacturing high-end spunbond and fibers for carded nonwovens.

International Fiber Journal had the opportunity to talk to Dr. Ingo Mählmann, Vice President Sales and Marketing for the nonwoven business unit at the Oerlikon Manmade Fibers segment.

Dr. Mählmann, the demand for nonwovens has been rising since 2002. What is the reason for this ongoing growth?

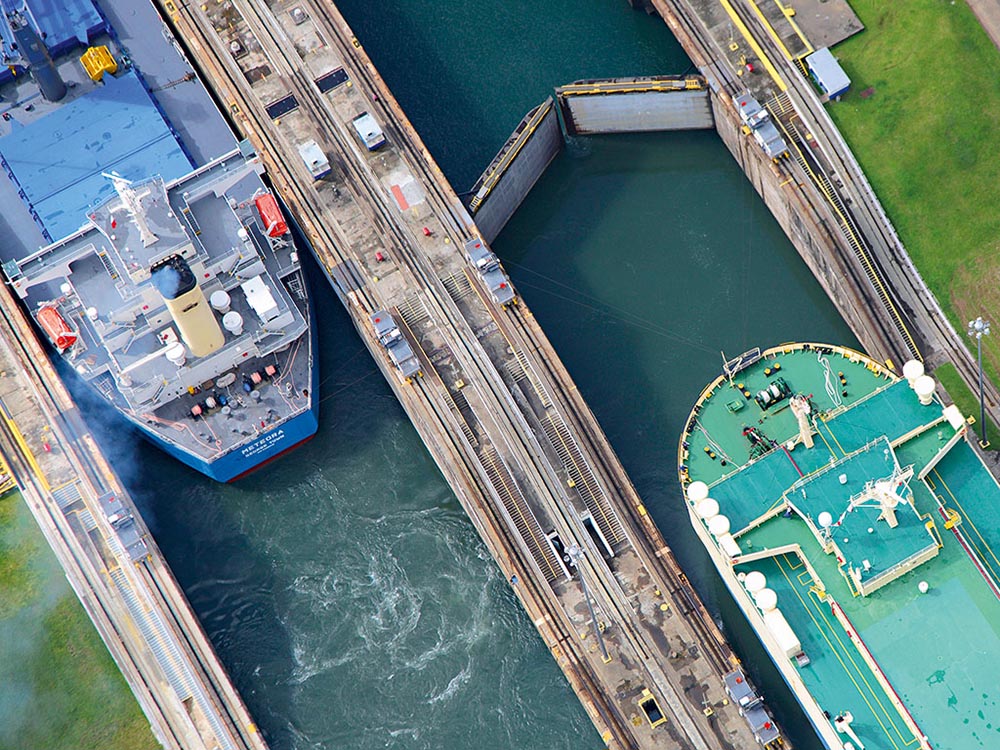

Huge infrastructure programs, particularly in China and India as well as in other emerging countries, are being implemented,

Winning Combinations

By Adrian Wilson, International Correspondent

While not generally a field characterized by frequent innovation, a potentially disruptive new technology is being introduced to the North American geotextiles market by Greer, South Carolina-based Haydale Technologies.

Haydale is an advanced materials group with a focus on the integration of nanomaterials into next-generation commercial technologies and industrial materials, with six facilities in the USA, Europe and the Far East.

Invisible, but indispensable: geo-synthetics in ground works

The quality of nonwovens is determined by the stabilization, the application and the fiber quality. As a proven expert in spinning, Oerlikon Neumag beneficially deploys its many years of expertise here both for its spunbond and staple fiber technology. Hence, Oerlikon Neumag is able to offer solutions for processes and systems for manufacturing high-end spunbonds and fibers for carded nonwovens.

Since 2002, nonwovens have experienced a sharp rise, with 6 percent annual growth with regards to its use in geotextiles.

Invisible, but Indispensable: Geo-Synthetics in Ground Works

The quality of nonwovens is determined by the stabilization, the application and the fiber quality. As a proven expert in spinning, Oerlikon Neumag beneficially deploys its many years of expertise here both for its spunbond and staple fiber technology. Hence, Oerlikon Neumag is able to offer solutions for processes and systems for manufacturing high-end spunbonds and fibers for carded nonwovens.

Since 2002, nonwovens have experienced a sharp rise, with 6 percent annual growth with regards to its use in geotextiles.

Extending pavement funding with geotextiles

The American Society of Civil Engineers (ASCE) Report Card for America’s Infrastructure gave a grade of D to America’s Roads. “Over 42% of Americas roads are congested costing the economy an estimated $101 billion in wasted time and fuel annually.” It is estimated that over $170 billion needs to be spent annually just to maintain America’s roads and bridges (ASCE Infrastructure Report Card). The 2015 Transportation Reauthorization and Reform Act of 2015 provides only $46 billion per year. These kinds of budget deficits require innovative solutions to provide more efficient and sustainable road system solutions.