Exploring New Entry and Exit Routes for Carbon Fiber Composites

Despite its currently unmatchable benefits in enabling the production of lightweight parts that are exceptionally strong and have been critical to reducing emissions in numerous end-use applications – most significantly the aerospace industry – carbon fiber remains based on oil-based raw materials and is extremely energy intensive to produce, as well as very expensive to buy.

As a result, much research is being undertaken to develop lower-cost alternative monomers to polyacrylonitrile (PAN), the usual precursor material for carbon fibers, including biobased materials.

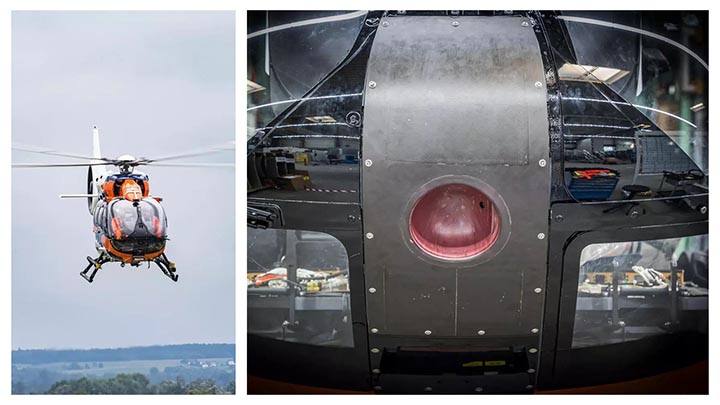

Flight Tests

Airbus, for example, has recently been flight testing an experimental and non-structural composite nose panel on its PioneerLab helicopter which is based on biobased carbon fibers made from acrylonitrile derived from the capture of atmospheric carbon dioxide. The new panel is said to be as stiff and strong as a conventional part and the chemically identical acrylonitrile is used to produce the fibers with the same performance level. It is obtained from sustainable ISCC-certified non-fossil feedstocks such as wood and food waste, recycled cooking oils and algae, along with renewable sources of ammonia and propylene.

A full life cycle analysis undertaken by Airbus suggests that producing sustainable acrylonitrile and other bio-based chemicals and intermediates generates significantly less CO2 than the crude oil alternative. The industrialization of these products, however, is in its infancy and scaling up to the extent where corresponding CO2 reductions move the dial will require regulatory commitment and massive capital investment.

For now, the PioneerLab nose panel remains a proof of concept. The challenge for Airbus and others is to work with supply chains to make bio-fiber production economically viable, and to ensure it can be ramped up cost effectively to meet accelerating aircraft production.

Recycling

The production of composite parts can also be very wasteful, with scrap rates averaging 30-40%, and both this waste, as well as finished parts at end-of-life, have to date largely being disposed of by landfilling or incineration. Globally, it has been estimated that around 62,000 tons of waste is generated simply from manufacturing operations each year.

As a result, there has also been an intensive supply chain-wide campaign to develop recycling routes for carbon fiber. A fast-rising star in this field is Paris-headquartered Fairmat.

Rapid Expansion

Having only been founded in 2020, Fairmat has successfully secured the funding – around $45.5 million to date – to enable it to open its first ‘virtuous recycling’ plant in Bouguenais, close to Nantes in France, at the end of 2022, and this year, to bring its technology to the USA, with a plant in Salt Lake City, Utah, currently ramping up operations.

“Fairmat is here to enable a wave of sustainable progress, putting advanced recycled materials at the heart of forward-thinking industrials worldwide, to make product manufacturing more circular,” says founder Benjamin Saada. “The idea is not only to substitute with recycled materials, but to produce differently while at the same time creating a new ecosystem with our customers and partners.”

Building Blocks

Traditional waste-management techniques involving pyrolysis or solvolysis use significant amounts of energy, mitigating the environmental benefits of the recycling of carbon fiber. Mechanical recycling to date has meanwhile involved chopping and milling which significantly compromise fiber strength.

By contrast, Fairmat’s process uses proprietary cutting technologies and robotic tools equipped with machine learning to disassemble the carbon fiber components and convert the pieces into the building blocks for new parts and products.

Using AI tools such as digital twins to model different 3D arrangements during the design phase, the company can assemble its recycled carbon chips into a variety of layouts and structures. These simulations enable it to customize the mechanical properties of the resulting product, such as, for example, extremely low weight for transportation components and localized, unidirectional strength for impact surfaces. Big data combined with AI algorithms meanwhile ensure absolute traceability and generate better understanding of the materials to continuously improve the process.

It is planned that the Bouguenais plant in France, which has an initial annual capacity of 3,500 tons, will eventually deploy over a hundred robotic arms to allow the company to upscale the operation and treatment capacity.

The company has budgeted for an annual R&D spend of between €7-8 million for continuous improvement through machine learning, and the current team of 80 people will eventually swell to 400. Fairmat is seeking to recruit the best talent in robotics and data science and further intends its plants to become self-sufficient in energy.

Supply Chain

In Europe, Fairmat has rapidly secured the supply of around 35% of all available carbon fiber scrap across the continent, via partnerships with leading manufacturers including Dassault Aviation, Exel Composites, Hexcel, MerConcept, Siemens Gamesa and Tarmac Aerosave.

Exel Composites, headquartered in Mäntyharju, Finland, is now transferring the carbon fiber scrap from its plants in Europe to Fairmat, for the production of second-generation carbon fiber chips, as well as high-performance composite parts.

“Fairmat’s recycling methodology enables its products to retain the high strength and stiffness of the original embedded fibers,” explains Kim Sjödahl, senior VP of technology and sustainability at Exel. “Combined with its minimal energy input, Fairmat’s process is genuinely game-changing for sustainability in the composites industry. What’s more, the successful recycling of process waste also opens possibilities to recycle the end-of-life waste from our customers.”

Fairmat’s materials are said to be ten times less expensive than new composites as well as being significantly more resistant and twice as light as aluminum. They represent a potential replacement for many materials, from wood to steel, in addition to new composite parts.

In addition, with a lifespan of about 20 years, the materials are said to be capable of being recycled up to five times without loss of performance. Current markets being served include sports equipment, automotive and medical components

Easily Replicated

The new plant in Utah has very quickly followed on from a study trip carried out by Saada and Fairmat director Antoine de Turckheim in 2023, which confirmed very robust carbon fiber and composite activities in the region, with reference companies such as, for example, Albany Composites, Northrop Grumman and TCR Composites, but also the absence of a structured recycling sector.

“The Salt Lake City site has several advantages, and the local authorities in Utah rapidly facilitated the negotiations,” said de Turckheim. “Additionally, in May this year we concluded a long-term agreement with Hexcel, which operates a major prepreg plant in Salt Lake City. The strengthening of our ties with Hexcel obviously represented a valuable foundation for the new plant. Our industrial model is also easily replicable as it relies on the cloud and uses AI.”

“Recycling advanced materials like carbon fiber composites is one of the strongest actions we can take to accelerate the decarbonization of the manufacturing sector,” added Saada. “We are thrilled to see our vision of a next generation of materials come to life as we are accelerating our production and expanding our international development.”