Up to 95 % light reflectance: Kelheim tests new IR-reflecting viscose specialty fiber

Kelheim Fibers, a leading manufacturer of viscose specialty fibers, has completed the next step in the development of IR-reflecting fibers. During the last months, the incorporation of mineral IR-reflecting particles has been …

Goulston Tecnologies achieved new ISO certification

Goulston Technologies, Inc. achieved certification to the ISO 14001:2004 Environmental Management Standard. The certificate is issued by American Global Standards and awarded on October 29, 2015. American Global Standards is …

Oerlikon’s Manmade Fibers Segment wins large orders for latest staple fiber technologies

Based on latest technologies presented at ITMA in Milan this fall, Oerlikon’s Manmade Fibers Segment received a number of large orders totaling more than CHF 50 million for their Oerlikon …

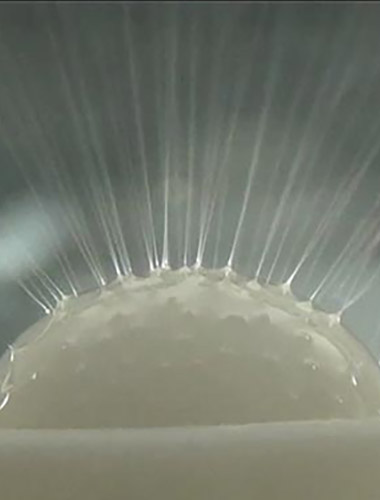

Enabling breakthrough technologies using nanofiber expertise

By Haydn Kriel, R&D Manager; Dr. Megan Coates, Senior Scientist; and Dr. Eugene Smit, CEO, The Stellenbosch Nanofiber Company (Pty.) Ltd. (SNC)

Nanofibers have a range of applications in medicine, cosmetics, environmental monitoring, energy generation and the manufacture of smart materials. The high surface area-to-volume ratio of these nanomaterials is highly beneficial for drug delivery and catalysis, and their controllable pore sizes, that can be tailored to selectively exclude components like bacteria or pollutants, makes nanofiber webs ideal for filtration, tissue engineering and wound care. Nanofibers are also versatile in that additives can be encapsulated within the fibers or coated on to the surface. The choice of the polymer and the nanofiber dimensions can be changed to obtain specific material properties.

Application of high-productive and high-efficient needle punching equipment in superfine fiber synthetic leather

By Du Xiaojing, HI-TECH HEAVY INDUSTRY CO., LTD.

DuPont first introduced the synthetic leather Corfam made of synthetic fiber-based nonwoven in the 1960s. In the following decades, the fast-growing global economy and improving living standard boosted the growth of nonwoven-based synthetic leather similar to natural leather in structure and performance. Today, needle punched synthetic leather substrate has become the main material for synthetic leather products, with its compact three-dimensional structure, interlaced structure similar to the collagen protein of natural leather, fine simulation, excellent physical performance, and low production costs.