Student Spotlight: Reusable textiles for liquid and virus repellency

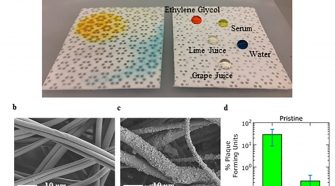

Anthony John Galante is pursuing a Ph.D. in Industrial Engineering at the University of Pittsburgh, where he is conducting research on microbe repellent surfaces at the Lab for Advanced Materials …

SDL Atlas introduces Stretch Fabric Fixture technology

SDL Atlas has developed a new fixture for testing stretchy fabrics on their MMT: Moisture Management Tester. The new Stretch Fabric Fixture will offer more accurate testing for how a …

Movers & Shakers – July 2020: Purdue-affiliated Poly Group partners with Royer Corp. to develop new antimicrobial material options

In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant …

Oerlikon’s automated wiping robot reduces yarn breaks

Oerlikon Barmag’s first wiping robot has now been operating in India since the end of 2019. The even wiping process provides reduced yarn break rates and higher full package rates. …

Eastman expands Naia fiber portfolio

Eastman, the maker of sustainably sourced Naia cellulosic filament yarn, announced the expansion of its Naia fiber portfolio. Naia is able to be blended with other eco-friendly materials, such as …