Crypton and Hologenix partner for Crypton Celliant upholstery fabric

The Crypton Companies (Crypton LLC and Nanotex LLC) have partnered with Hologenix to create Crypton Celliant, a woven upholstery fabric with Celliant. Celliant is ethically sourced minerals embedded into fibers …

Bolger and O’Hearn expands in fluorine-free water repellence

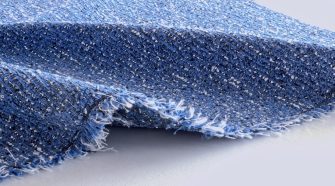

Bolger and O’Hearn introduced its Shell-Tech Free, a fluorine-free water repellent, engineered for sustainability and easy application at a mill. Shell-Tech Free is resistant to water, stains from soda, wine, …

HeiQ announces cellulose yarn made from carbon-negative fiber

HeiQ launched HeiQ AeoniQ, a cellulose yarn based on a fiber derived from carbon-negative materials. The fiber is made from third generation cellulose biopolymers that, during growth, bind carbon from …

Movers & Shakers – October 2021: INDEX attracts large audience in Geneva as global nonwovens community reunites

In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant to …

RadiciGroup to showcase new line of PPE at A+A trade fair

RadiciGroup is exhibiting at the A+A trade fair in Dusseldorf, Germany, from October 26 to 29. RadiciGroup’s stand will feature its new line of protective workwear, Radipeople. This personal protective …