The weight profiling product range of ANDRITZ – consisting of ProDyn and ProWid – has been extended by ProWin, a combination of the two existing systems that allows nonwovens producers to achieve optimum weight profiling at the crosslapper delivery and increase their process speed by up to 15% at the same time, according to the company. ProWin combines the long-term process experience and in-depth knowledge ANDRITZ has on needlepunch lines with software to synchronize action across the line.

Guillaume Julien, Head of Needlepunch Sales at ANDRITZ Nonwoven, said, “We have developed a self-regulating, advanced technology to reduce fiber deposits at the edges of the web and eliminate the “smile” effect across its width. ProWin enables producers to optimize the CV ratio autonomously and precisely while also generating significant fiber savings of up to 10% and increasing production speed. Thus, it also provides a faster ROI.”

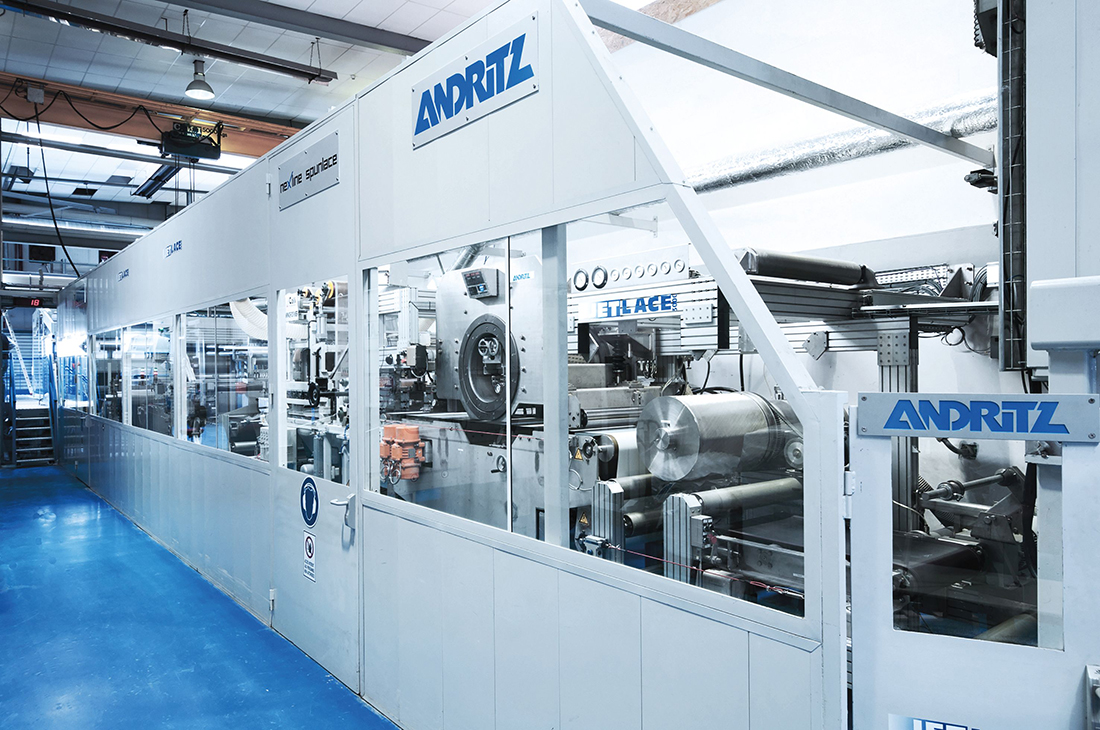

When it comes to the spunlace (i.e., hydroentangle) process, a better product quality can be obtained by ensuring that the different equipment units in the production line are consistent with one another. The TT card, the Jetlace hydroentanglement unit, and the neXdry through-air dryer are the perfect combination to obtain premium visual quality and characteristics in the web. For an equivalent amount of fibers, this set-up is designed to produce an even web with significant bulkiness and an excellent MD:CD ratio without impacting the production capacity.

Maximizing performance by minimizing the raw material input and the amount of waste produced is a real driver of cost optimization. This is why ANDRITZ has created and integrated a solution that allows nonwovens producers to retrieve the wasted edges of their spunlace fabric and re-use it as recycled fibers. As a result, roll-good producers can even obtain the same web characteristics as when using virgin fibers, and most importantly, the exact same quality.

ANDRITZ also offers – under the brand Metris – ANDRITZ digital solutions – a variety of several service apps for optimum customer benefit. The Metris Cost Management app is used to track raw material consumption. It is an advanced system aimed at monitoring fiber consumption and allowing in-depth diagnoses to investigate raw material losses and savings grouped by different process areas. Thanks to this Metris application, ANDRITZ customers are able to optimize their system’s consumption of raw materials.