Short cut PES

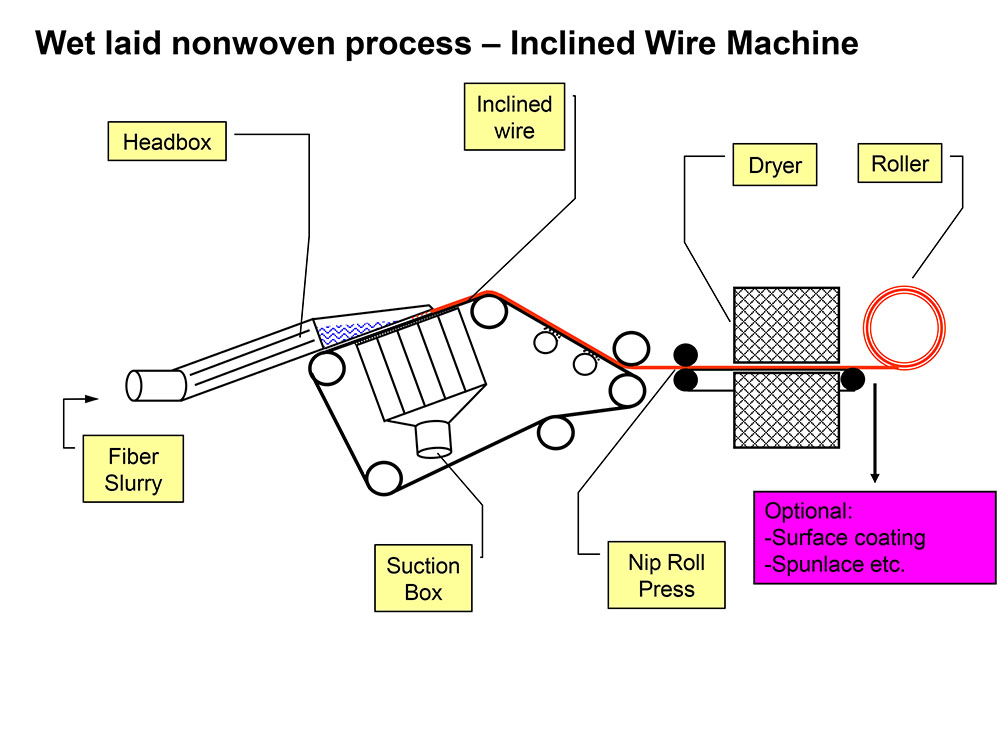

The wetlaid process is a core process at nonwoven producers that focus on uniformity, light-weight and strength. Wetlaid products are suitable for many different technical applications such as automotive, filtration, medical, hygiene, wallpaper, packaging, embroidery, construction material, etc.

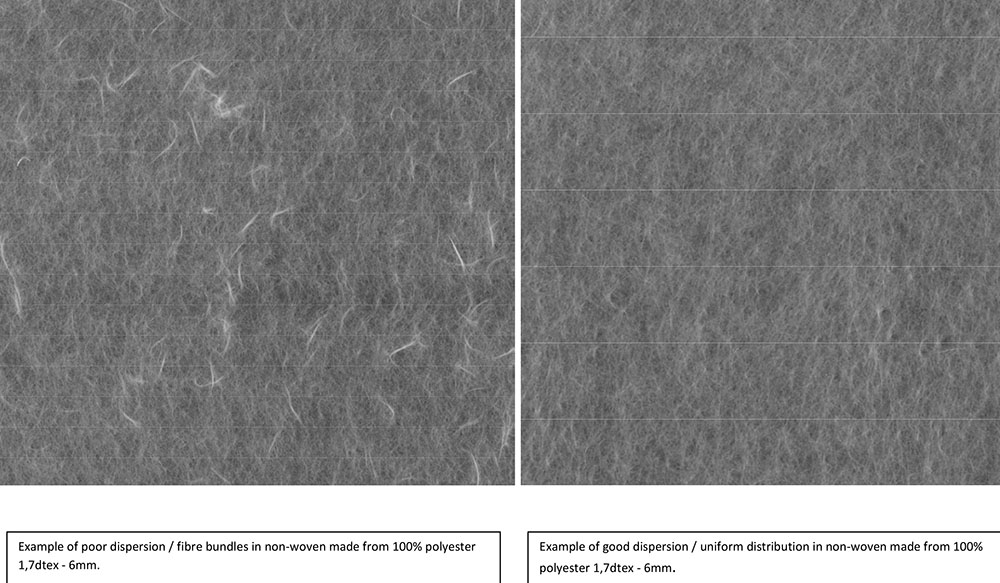

Wherever more demanding nonwoven products and papers with an outstanding uniformity and without any kind of defects are required, the wetlaid process is a good option for which fibers with good dispersion in water are essential. The dispersion of the short cut is mainly dependent on fiber type, diameters, cut length, cross section and surface characteristics.

Polyester short cut improves the wet and dry strength, tear and burst strength and the wet dimensional stability when partially replacing wood pulp in papers and wet laid nonwovens. Depending on the end use of the final sheet, the polyester fiber percentage in the recipe can range from a few percent to almost 100%.

ADVANSA is producing specially engineered short cut fibers, which fulfill all requirements needed for such applications. The fibers have a specially modified surface for a rapid and effective separation. Therefore, using moderate shear forces, the short cut fibers are evenly dispersed in water.

ADVANSA fibers can be used for processing in horizontal wire (Fourdrinier) paper machines (cut length in the range of 3 to 6mm) as well as inclined wire machines with cut lengths up to 30 mm and even higher. ADVANSA’s portfolio includes customized polyester fibers with modified cross-sections, colored and binder fibers. The range of the linear density is between 0,3 dtex to 17,0 dtex. Various grades are compliant with the requirements for food contact articles as defined by EFSA, BfR and FDA guidelines. Current R&D works focus on further reduction of the linear density into direction of 0,2 dtex and even finer following the requirements of filter media producers. Further commercial types are bicomponent fibers with polyethylene terephthalate core and lower melting sheath polymer. For end products that are designed for compostability ADVANSA offers dispersible poly lactonic acid (PLA) fibers. For sustainable end uses with particular low carbon footprint and non-renewable energy consumption figures, polyethylene terephthalate fibers from post-consumer recycled feedstock are also an available option.

This environmentally friendly option is made by using an innovative recycling technology – out of raw material purchased from ADVANSA’s partner Reiling. These are PET bottle flakes from European Collection System. The traceability of the PET bottle flakes back to the bottle feed stock guarantees a high-level of quality control. As an external certification for the use of post-consumer recycled raw material in the relevant fiber products, ADVANSA’s operation has been awarded the GRS-label.

Using the state-of-the-art production technology at ADVANSA, this raw material is melted and pressed through super-fine filtration. In order to avoid any defects in fibers, the polymer is spun under strict process control.

In further steps, fibers obtain their final physical as well as their necessary surface properties.

Precise cutting length is ranging from 3mm to 38mm depending on the subsequent application.

Each intermediate step in the production process chain is strictly controlled, resulting in uniform product quality, which is proven by regular lab tests. Hence, the quality of recycled and non-recycled material is comparable.

Thanks to fully automatic packaging processes, the fibers are filled in bags or big bags on pallets, e.g., in 25 kg plastic bags, 150 kg to 400 kg big bags, or other packaging sizes upon request.

With almost 50 years of experience – founded on its heritage of DuPont – ADVANSA is well recognized with its innovative fiber production based in Germany. The company focuses on the optimal development and production of innovative as well as technologically advanced fibers. ADVANSA allows a high productivity within the supply chain and functionalizing of the final products. Thanks to its responsiveness, ADVANSA reacts to changing customer demands and supports developments in order to offer and implement competitive, customized products and individual solutions.

One of ADVANSA’s key values guiding the development of new products is sustainability while continually improving the safety, health and environmental performances. The company’s efforts and achievements and a wide range of fibers produced by ADVANSA have been recognized by international ecological certification and awards such as the EU Eco-label and the European Greenlight Program.