In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant to our industry from manmade to natural to bio-based fibers, innovations in nonwoven, woven, braided and technical textiles, technologies for additives, bonding, coatings and polymers, and applications from apparel to hygiene to transportation, and more. Here we will post news stories relevant to textile fibers and their downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Matt Migliore at mmigliore@inda.media.

Most recent update: June 30, 2020

Stefan Moll named Keifel’s new CTO

Kiefel GmbH, member of the Brückner Group, has named Stefan Moll as its Chief Technology Officer. He is responsible for the technical matters, with a particular focus on the company’s global medical engineering business.

“Stefan Moll will concentrate primarily on new technical developments in the medical division. He takes over the management of central technical areas of production while driving the Kiefel digitalization strategy,” said Dr. Axel von Wiedersperg, Brückner Group’s CEO.

Most recently, Moll was the CTO at Fette Compacting Group, where he was responsible for the company’s realignment in the areas of digitalization and process optimization. Previously, he was Managing Director and Member of the Board of Directors at Comet AG.

Kiefel is a market leader in design and manufacture of plastics processing. The company specializes in thermoforming and joining technology.

Source: kiefel.com

RKW sells medical films and laminates business

RKW has decided to sell its production of embossed films and laminates for the medical industry RKW ACE S.A. (“ACE”) in Liège, Belgium.

ACE has been sold to Standard Investment, an investment company focused on the Benelux and Nordic countries. Standard Investment has acquired 100 percent of ACE’s shares. As of June 19, 2020, ACE operates as an independent business. The purchase price is not disclosed.

“We are convinced that ACE will remain a strong stand-alone business with great growth potential”, says Harald Biederbick, CEO of the RKW Group.

Established in 1973, ACE was among the first film producers for the hygiene and medical disposables markets. After becoming part of the RKW Group in 1999, ACE continued its business success and, today, is one of the global market leaders in its field of expertise. The company was an early member of EDANA, the global trade association for the nonwovens industry.

Source: rkw-group.com

Johns Manville announces changes at president and chairman positions

Johns Manville (JM), a Berkshire Hathaway company, announced today that Bob Wamboldt will become president and CEO on Sept. 1, 2020. Mary Rhinehart, the company’s current chairman, president and CEO, will retain the role of chairman.

Wamboldt joined Johns Manville in 2003 and became president of JM’s Insulation Systems business in February 2017. He earlier led the Engineered Products North America and Roofing Systems businesses at JM. Wamboldt is also chairman of the North American Insulation Manufacturers Association and previously served as president of the Asphalt Roofing Manufacturers Association.

“I have been privileged to lead each of our businesses and learn first-hand the strength of the Johns Manville customer relationships, products, technologies and people,” Wamboldt said. “I look forward to working with the JM team and our customers to make the company even stronger in the global markets we serve. I also want to thank Mary for her leadership and guidance over the years and know I will benefit from her continued support as Chairman.”

Before joining Johns Manville, Wamboldt worked 16 years at PPG Industries Inc., where he held a variety of positions in the company’s Fiber Glass and Coatings divisions. He earned a bachelor’s degree in chemistry from Lehigh University. He and his wife live in Denver.

Rhinehart became Johns Manville’s President and CEO in 2012 and assumed the additional role of Chairman in 2014. Before becoming President and CEO, she was the company’s Chief Financial Officer for eight years. During her more than 40 years with Johns Manville, she also held leadership roles in treasury, supply chain, M&A and human resources, and she managed several of the company’s business units.

Source: jm.com

INDA presents critical metrics on North American Nonwovens Supply & Trade

Key highlights and insights from the seventh edition of the INDA North American Supply Report will be revealed during two upcoming webinars. The report found that North American nonwoven production exceeded capacity increases for the third year, while nonwoven material trade decreased.

The webinars will start at 2 p.m. on June 23 and June 24. The first webinar will cover capacity and production supply-side developments and crucial supply and demand balance as the market entered the pandemic. The second will highlight trade, imports and exports of nonwoven materials.The programs will include a 25-minute live webinar presentation with 25 minutes dedicated to answering members’ online chat questions in real-time.

A sample of findings from this year’s Supply Report include:

- In 2019, North American nonwoven capacity increased to 5.479 million tons, a net increase of only 0.9 percent (51 thousand tons) over 2018. This growth figure accounts for the addition of new lines and machine productivity increases as well as line closures to arrive at a net increase growth figure. In the last three years, 64 lines have come online and 23 lines have shut down. The majority of the new lines are producing engineered materials for transportation, home/office furnishings, and filtration markets.

- North American imports and exports, in tonnage, decreased 3 percent and 18.6 percent, respectively, year-over-year, led by declines in trade with China. However, the trends of downward exports and upward imports continued. Over the last five years, exports have declined 7.7 percent annually and imports have increased 7.8 percent annually. Even with the significant shifts in North American trade dynamics, nonwovens tend to stay where they are produced, with the net trade balance (imports less exports) accounting for less than 5 percent of the region’s capacity.

INDA webinar registration page: https://www.inda.org/inda-webinars/

Source: inda.org

* International Fiber Journal is owned by INDA, Association of the Nonwoven Fabrics Industry (inda.org).

Ascend launches zinc-based antimicrobial technology for facemasks, other textiles

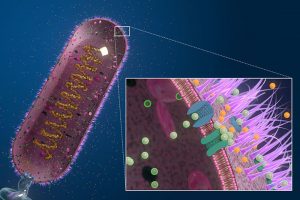

Ascend Performance Materials has introduced Acteev Protect, a breakthrough technology specially formulated to guard against the growth of mildew, fungi and other microbes to keep textiles and nonwoven fabrics fresher for longer.

The technology is a leap forward in protection for facemasks, apparel, upholstery, air filters and more, according to Lu Zhang, Ph.D., Ascend’s vice president leading the Acteev launch. “Bacteria, mildew and other microbes growing on fabrics and filters cause the item to break down, discolor and give off unpleasant smells,” she said. “Acteev Protect guards against that microbial growth, keeping the articles clean.”

The technology has been in development for several years, but with the recent shortage of articles resistant to microbial growth, Ascend accelerated the product launch by partnering with independent labs for testing and reallocating resources to scale up production. “The current global scarcity of microbe-resistant materials is not going to end unless manufacturers are able to obtain the right media,” Dr. Zhang said. “We saw a way we could quickly meet those urgent needs with this innovative technology.”

Acteev Protect combines zinc ion technology with polyamide-based woven, nonwoven and knit fabrics. The active zinc ions are embedded into the polymer matrix, providing a long-lasting solution that does not wash away, unlike topical finishes or coatings. The polyamide fabrics are durable yet soft to the skin, and the nonwoven filtration media – available as nanofibers, meltblown and spunbond – efficiently keep out unwanted particles.

Other products use silver as an antimicrobial, Dr. Gopal said, but that metal comes with unwanted environmental consequences. “Silver is typically used as a finish or a coating,” he said. “That process is water-intensive, and the excess silver has to be disposed of, eventually ending up in our waterways.”

Zinc, however, is labeled Generally Regarded as Safe by the U.S. Food and Drug Administration.

Source: ascendmaterials.com

NCTO names David Roberts of Cap Yarns as chairman, announces leadership appointments

The National Council of Textile Organizations (NCTO), which represents the full spectrum of U.S. textiles from fiber through finished sewn products, appointed its chairman and vice chairman, NCTO elected chairs for each of its four councils. NCTO is comprised of four councils to ensure a broad representation of the industry supply chain. Each council has an allotted number of members who are elected to the association’s Board of Directors, in addition to the Executive Committee.

“I am pleased to announce our new officers, council chairs, and board and executive committee members for NCTO’s 2020 fiscal year,” said NCTO President and CEO Kim Glas. “David Roberts, CEO of Cap Yarns, has been elected our new chairman and succeeds Leib Oehmig, CEO of Glen Raven Inc., who did an outstanding job serving in the role for more than a year.”

Read the full announcement on NCTO’s appointments: http://www.ncto.org/6113-2/

Source: ncto.org

Beckmann Converting sells hot-melt adhesive gravure roll bonding assets; increases focus on ultrasonic bonding

Beckmann Converting announced that it is increasing focus on its ultrasonic bonding technologies with the sale of its remaining assets for hot melt adhesive gravure roll bonding to an undisclosed buyer.

“Applications best suited to hot melt adhesive gravure roll bonding have become highly specialized over the past few years, resulting in very short production run requirements,” said Ray Piascik, director of sales and marketing at Beckmann Converting. “We concluded that our current and prospective customers could be served best if we further extended our concentration in ultrasonic bonding capabilities.”

Critical end-use applications are driving textile designers to create innovative multi-layer textile packages to meet product performance requirements, explains Piascik. “We are being challenged by customers across all markets to accomplish results using ultrasonic bonding technology in novel, specific ways. By leaving the hot melt space, we can put our full attention to achieving success for our customers in the ultrasonic bonding arena.”

Beckmann Converting is focused on converting continuous wide web, roll-to-roll, technical textiles into multi-layer composites with the application of ultrasonic bonding technologies. The company’s multi-layer capabilities allow for the bonding of materials into high-performing new products and new uses that were often considered to have been previously impossible to manufacture.

Source: beckmannconverting.com

Bast Fibre Technologies announces $4.5M equity financing for natural fiber technology

Bast Fibre Technologies Inc. (BFTi), a natural fiber engineering firm focused on the nonwovens industry, announces the closing of a $4.5M CAD equity financing. The investment, which was led by the Lightburn group and Natural Products Canada (NPC), includes significant participation from existing investors and from new individual investors.

“Since our founding in 2016, BFTi has been driven to perfect our natural fiber technology and establish a robust IP suite,” said Noel Hall, Chairman and CEO of BFTi. “The company is now ready to take the next step and begin the commercial phase of our growth. This financing will allow us to complete trial work with our customers, file additional IP and finish the build-out of a dedicated bast fiber processing facility. BFTi is well placed to meet the sustained demand for disinfecting wipes created by the COVID-19 pandemic, at a time when new legislation forthcoming in multiple jurisdictions requires a shift from synthetic to natural fibers.”

According to BFTi, its fibers are completely natural, plastic free, fully compostable, sourced from an annually renewable crop, and provide a net reduction in greenhouse gas emissions. In addition, BFTi says its proprietary fibers offer enhanced performance characteristics when compared with traditional synthetic and semi-synthetic fibers.

“Our investment is crucial to furthering BFTi’s mission to displace synthetic and semi-synthetic fibers in the nonwovens industry, and to help create single-use products that are both environmentally and economically sustainable,” said Shelley King, CEO of NPC. “Most of the hemp grown in Canada today is used for CBD production or as a seed crop for food. BFTi will play an important role in building long-term demand for hemp straw and realizing the vision of whole hemp plant utilization.”

In conjunction with the closing of the financing Ben Lightburn, an experienced CEO and natural products entrepreneur, has joined the BFTi Board of Directors. Mr. Lightburn will help the company transition to becoming a commercial-stage enterprise. “I am excited to join the board of BFTi and to contribute to the company’s next phase of growth,” said Mr. Lightburn. “There is no doubt that consumers are driving the shift towards natural products and that with impending new regulations limiting the use of synthetic materials the nonwovens industry is certainly feeling the pressure to adopt more sustainable fibers in its supply chain.”

Source: bastfibretech.com

The Fiber Year 2020 now available

The Fiber Year GmbH has released the latest edition of its annual The Fiber Year report. The Fiber Year 2020 includes a distinct differentiation between fiber supply and the volume entering textile processing. This reveals fiber inventory changes and delivers enhanced insights into processing volumes. A projection for last year’s final end-use enriches key figures along the textile value chain to illustrate different dynamics from supply to demand at the retail stage.

In addition, the report expands world supply by spunlaid nonwovens, which account for almost one kg per capita textile demand by now. This web-forming process skips a production stage as the polymer-based technology directly delivers a finished fabric. The video below provides additional details on The Fiber Year 2020.

The Fiber Year GmbH was founded in 2010 by textile industry veteran Andreas Engelhardt. With a focus on providing expertise, analyses, strategy consulting and customized solutions to the international textile industry after 18 years in textile machinery manufacturing business at Barmag, Saurer Management and finally Oerlikon as senior manager at Oerlikon Textile International Business, Engelhardt has a strong understanding and grasp on the nuances of the global textile industry. The Fiber Year report dates back to 2000, with this year’s edition marking its 20th anniversary.

Source: thefiberyear.com

Dornbirn-GFC 2020 cancelled; online program announced

The 2020 Dornbirn-GFC, scheduled for 16-18 September, has been cancelled due to the ongoing impacts of COVID-19. As an alternative, event organizers will be offering some lectures and discussions in the form of webinars.

The online program will open with a keynote, titled “Green Deal – Implications for the textile Industry” and the awarding of the Paul Schlack/Wilhelm Albrecht Prize. Other lectures will focus on:

- Leading polymer recycling technologies

- Smart, integrated, digital textile production chain

- Lessons learned from packaging – EPR schemes for Textiles

- Circular economy

- PPE production – a challenge for the industry

Dornbirn-GFC dates for 2021:

60th Dornbirn-GFC, 15 – 17 September 2021

1st Dornbirn-GFC Asia, 2 – 3 March 2021

Source: dornbirn-gfc.com

Elsner acquires Paco Winders Manufacturing

ELSNER, a leading manufacturer of automation machinery to convert papers, films, foils, plastics and nonwovens, has acquired the Intellectual Property of Paco Winders Manufacturing from OX Industries. The purchase includes all IP and drawings in relation to Paco machinery and parts. The previous Paco plant, located in Philadelphia, will remain closed as the business shifts to the ELSNER corporate headquarters located in Hanover, PA.

“We’ve been a local resource, making parts for Paco customers for the past five years. The Paco plant was shuttered in December, and since then we have realized there is a need in the marketplace to provide continuity of service to Paco customers,” said Bert Elsner II, President/CEO of ELSNER. “Having acquired the IP and official drawings, we can now more easily provide that service beyond locally, nationwide. The purchase is aligned with our Contract Manufacturing business unit and we are looking forward to better serving our Paco customers.”

Source: elsnereng.com/

SGS-IPS Testing adds ISTA 6-Amazon.com test methods

SGS-IPS Testing of Appleton, Wisconsin, has announced the expansion of its packaging testing lab and services. The company now offers the full suite of International Safe Transit Association (ISTA) packaging tests including ISTA 6-Amazon.com test methods.

Under ISTA, there are a series of performance and development standards for product packaging that should be met for packages to safely make it through the transit process, from the originating distribution channel to the recipient’s doorstep.

SGS-IPS Testing, an ISO 17025 accredited and ISO 9001 certified organization, has received certification to perform all of the tests specified in ISTA’s 7-part series.

To add these high-demand testing services, the SGS-IPS Testing lab has installed the equipment necessary to simulate the distribution and delivery process for all types of packages – small parcels, individual shipping cartons, palletized products, insulated shipping containers and more. The tests performed range from drop tests and random vibrations to stack compression and forklift handling.

As packages go through the simulation of potential elements and hazards, the lab professionals at SGS-IPS Testing evaluate the packaging design and durability and identify issues that may affect safety, compliance or sustainability. After testing, the results and recommendations for packaging improvements are shared.

Source: ipstesting.com

INDA announces virtual component for Wipes Academy training course

INDA, the Association of the Nonwoven Fabrics Industry, announced a new virtual supplement to its seventh edition WIPES Academy training course – a training program dedicated to wipes raw materials and packaging suppliers, brand and private label wipe converters, wipes retail buyers, product developers, and professionals within the wipes supply chain.

Virtual WIPES Academy will enable those not able to attend the two-day course in person to experience the full educational content of this important wipes training, via a unique website link containing the full course instruction with audio and visuals to replay at any time from 30 minutes beyond real-time to any time “on demand.”

The course content provides a current and in-depth wipes education focused on consumer and industrial wipes raw materials, ingredients, design, production, cost implications, and packaging materials for the multi-billion dollar sector.

Taught by expert instructor, Chris Plotz, INDA’s director of education & technical affairs, and author of five wet wipe patents, both live and Virtual WIPES Academy, will be held in conjunction with the World of Wipes (WOW) International Conference, August 24-27, in Minneapolis, MN.

For more details and to register: worldofwipes.org/WIPES-training.html

Source: inda.org/

* International Fiber Journal is owned by INDA, Association of the Nonwoven Fabrics Industry (inda.org).