The past decade has seen a surge in demand for bio-based and environmentally sustainable products, motivated primarily by global challenges, such as marine litter and microplastic contamination and growing environmental consciousness. Responding to this change in public opinion, the European Union Parliament recently introduced a ban on single-use/disposable plastic goods from 2025.

The need for alternative and more sustainable materials has driven research towards the development of bio-based plastics from renewable feedstocks. However, current production capacity for bio-based plastics is only about 1 percent of the overall global capacity for plastics, and even though the annual growth rate for bio-based plastics is predicted to reach 20 percent, traditional plastics will continue to dominate in the near term.

The Bio Need

The textile industry is one of the largest consumers of bio-based materials, and 20-50 percent of all bio-based materials will be incorporated into textile products by 2030. To fulfill consumer demand, the textile industry needs access to high-performance fibers and yarns from 100 percent bio-based feedstock, as well as specific knowledge about the corresponding production processes. This is the research focus of the Aachen-Maastricht Institute for Biobased Materials (AMIBM), which develops novel bio-based materials from renewable feedstock and waste streams.

AMIBM has two key research pillars. The first is the development of methods for the synthesis of new chemical building blocks (monomers) for conversion into superior polymers. Because these methods are not yet available at the pilot scale, the second research pillar is to develop bio-based additives, such as colorants and plasticizers, to replace current polymer additives derived from fossil resources.

The inclusion of bio-based additives makes it possible to generate fully bio-based materials with properties comparable to commodity polymers. Given the demand for sustainable materials, it is necessary to exploit the innovation potential of the transition to a sustainable and bio-based economy, and to invigorate the pace of research to ensure such materials become commercially available within a reasonable timeframe.

Many research groups worldwide are developing bio-based polymers, seeking new bio-based materials, or improving the properties of existing ones. The chemical structure of bio-based polymers confers unique properties, such as compostability, but in many cases these benefits are outweighed by the need to include up to 30 percent (w/w) of additives to achieve the desired properties.

Examples of additives in textiles include – plasticizers and antistatics, which are needed to achieve high productivity during processing; nucleating agents and flame retardants, which are needed to achieve desirable mechanical properties; and safety and colorants to achieve the consistent quality demanded by industry and the visual appearance that underlies consumer acceptance. Most of these additives are derived from fossil resources, thus detracting from the sustainability of products made from bio-based polymers.

The first synthetic dye was discovered in the 19th century, and subsequent research has yielded many variants, resulting in the displacement of almost all natural colorants from industrial processes.

Synthetic colorants are less expensive, less susceptible to fading, and can achieve a consistent quality by chemical synthesis. However, concerns about their toxicity and unsustainable production methods have renewed the demand for natural colorants. Sensitivity to heat and ultraviolet (UV) light of natural colorants can be overcome by their modification before incorporation into polymers.

Overcoming Obstacles

Current and future challenges concerning the incorporation of natural dyes and pigments into molten polymers are being addressed in the Beauti-Fully Bio-based Fibres (BFBF) project, which involves textile industry representatives and four universities in the Netherlands.

Bath dyeing is the most widespread process used for textile coloring, despite the huge amounts of water pollution this causes. (The textile industry is the world’s second-greatest water polluter.)

The project partners therefore favor the dope-dyeing process for the incorporation of natural colorants, creating further challenges that need to be overcome. The natural colorants need to withstand the heat and mechanical stress inside the polymer extruder without losing their color intensity.

In the BFBF project, natural colorants are extracted from plants and assessed for their lightfastness and color intensity. After extraction and refining, the natural colorants are encapsulated within chemically altered nanoparticles to improve their lightfastness. Current research is focused on the successful coupling of the natural colorants to the nanoparticle surface to protect the colorants from the effects of mechanical stress and UV light.

AMIBM is also involved in the EU-funded Bio-based 100 percent (BB100) project under the patronage of Interreg. This project aims to develop novel bio-based additives for textile polymers, including bio-based plasticizers, flame retardants, colorants, stabilizers, adhesives and nucleating agents.

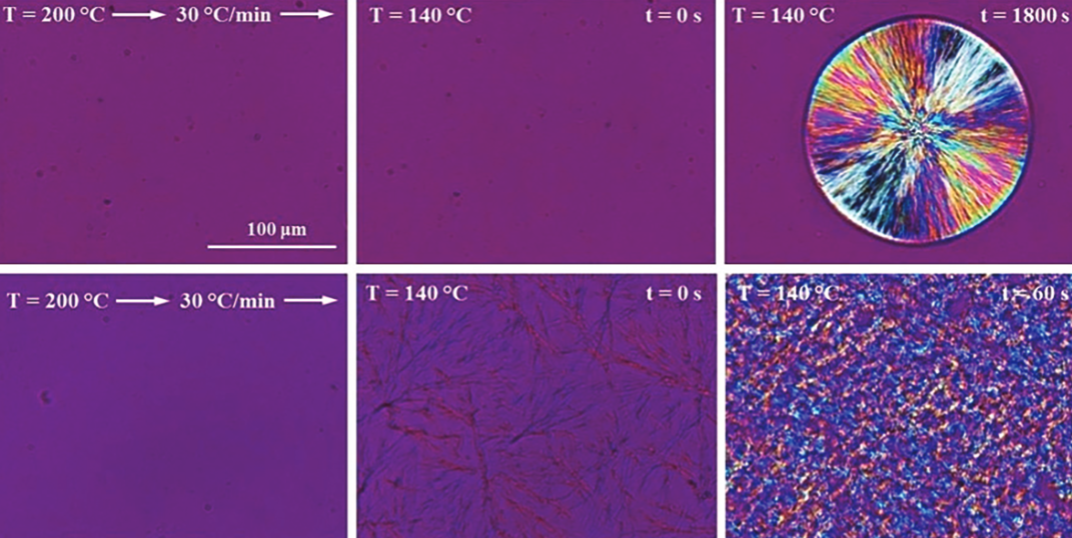

As an example, a bio-based nucleating agent has been developed for polylactic acid (PLA), today’s most widely used bio-based polymer. The use of PLA is hampered by its slow crystallization rate, making it difficult for use in applications requiring high mechanical strength because the mechanical properties of a polymer depend on the degree of crystallinity and orientation.

For melt spinning, the main process used for fiber production, the quenching time of the polymer melt is low owing to the high production speed. Nucleating agents are therefore necessary to achieve a sufficient degree of crystallization.

The role of AMIBM in the BB100 project is to develop and assess organic molecules that can self-assemble in the polymer melt during cooling and simultaneously act as nucleating agents. This allows the structure of the crystalline domains to be tailored, enabling the application-specific processing of PLA.

AMIBM is also seeking alternative organic molecules to compensate for chain scissoring and the accompanying decline in mechanical properties owing to the presence of alcoholic end-groups.

AMIBM’s ambitious research will facilitate the transition to an environmentally friendly and sustainable economy, but this is still at an early stage. To tackle the global challenge of marine littering, industry and academia should combine their skills and knowledge to create a powerful research alliance that will make this transition a reality and usher in a new bio-based future.