The Advanced Textiles EXPO is held in different North American cities each year, spanning both coasts and a sprinkling of key cities inland. The selection is driven by a combination of closeness to textile hubs, and good transport connections. Some exhibitors and speakers attend every year, while others come to the show when it is close to their manufacturing or client base. All of this means that each EXPO has a different flavor, so that brings a degree of certainty what to expect but enough unknowns to keep exhibitors and delegates on their toes – in a good way!

Advanced Textiles Expo 2024 was held in Anaheim, California at the Convention Center from September 24-26, 2024. It is the largest event of the Advanced Textiles Association (ATA), with exhibitors that include its membership but reaching beyond to attract manufacturers, research and testing institutes as well as delegates throughout the Americas, Europe and Asia. Once again it was held in conjunction with Sun Shading Expo North America, with that show organized by Messe Stuttgart. Exhibitor figures across both shows were 380, while attendee figures for the combined events reached 4,295 visitors from across the globe.

Steve Schiffman, President and CEO of ATA was pleased with the outcome and the feedback commenting, “Our community values networking opportunities that introduce them to new people and new ideas, and we’re delighted that expo is the platform where that happens.” He sees bringing the textiles industry together every year as a key function of expo, and to that goal the format is reviewed and refined constantly.

The AT Emerging Technologies Conference and “campfire” events have a pivotal role in achieving this, so that this year, for example, saw more speakers in the latter to allow for exhibitors to attend while being in easy reach of their booth. The conference is held the day before the expo starts and is then followed by more than 25 educational campfire sessions held during the show. The education topics ranged from textiles in the new space age to dealing with current and future PFAS regulations, how to be more environmentally conscious in fields such as medical textiles and technical textiles, to the potential (as well as the risks) afforded by artificial intelligence (AI).

New Space Age: Innovation and Testing in Space

MIT’s Dr. Juliana Cherston presented a paper at the Emerging Technologies Conference on the development of the first electronic sensor in Space. The presentation highlighted both the innovative development, and the complexity of stakeholders and funding channels involved.

The space blanket is being developed to protect the International Space Station (ISS) from orbital object threats that are both man-made and natural. While that is the immediate goal, Cherston also sees potential for a robust sensing fabric to be incorporated into the pressurized spacesuits to give astronauts a sense of touch.

In the development discussed, a sandwich structure of fabrics includes a Beta cloth known to be strong and highly durable against micrometeoroid impacts in extreme environments and capable of withstanding Ultra Violet (UV) exposure as well as radiation without suffering degrading. Vectran, spacer fabric layers are also included with a woven fabric incorporating a thermally drawn fiber developed by one of their collaborators, the Fibers@MIT Group, as a centimeter-thick sandwich of materials that is heated and stretched to sub-millimeter thickness that is not unlike pulling a multicolored taffy.

Counter intuitively, giving the heat and stretching process, the fiber emerges with a highly precise architecture that can be used for electronic and sensing functions, for example sensors for vibration, light, and temperature. These can then be woven directly into a fabric. Without sufficient data to simulate testing on Earth, the fabric “quilt” has been placed in a sample holder and tested in Space for over a year on the ISS completing around 7,000 orbital cycles around the Earth before returning to MIT in February 2022. The complex logistics come with a financial cost met from a number of sources such as the IISS US National Lab, NASA TRISH, Accenture, Hayashi-ULVAC MISTI Seed Fund, MIT Media Lab Consortium and the MIT Media Lab Space Exploration Initiative.

The electronics industry is moving towards more flexible and miniaturized technologies such as Powerfoyle, a solar cell that can be seamlessly integrated onto curved surfaces to gather energy from outdoor as well as indoor light sources to deliver clean, sustainable energy.

Where Do Printed Electronics Sit Within the E-Textiles Industry?

E-fiber developments are growing in popularity but in her campfire presentation, Paige Mullis looked to the Consumer Electronics (CES) show for clues to how the electronics and textile industries are coming together from a printed electronics perspective. She pointed to a mutual interest from both industry sectors in finding ways to partner more effectively. The electronics industry is moving towards more flexible and miniaturized technologies such as Powerfoyle, a solar cell that can be seamlessly integrated onto curved surfaces to gather energy from outdoor as well as indoor light sources to deliver clean, sustainable energy.

With the global printed electronics (PE) market size valued at $10.76 billion in 2023, this is expected to reach $75.89 billion by 2033 according to Mullis, with printed heating, batteries and sensors key technologies. The markets for Smart Home, e-health, workplace and rehabilitation wearables as well as gaming are already established.

Irrespective of whether the application is in the home or on the body, the consumer is demanding that the technology be as discrete as possible to the point of invisibility. This points to greater integration between the electronics and the material – not an easy feat while being cognizant of the need to repair, replace components and disassemble at the end of life.

Perfluoroalkyl Substances (PFAS)

PFAS are created equal, that there is a variable level of

toxicity and bioaccumulation potential.

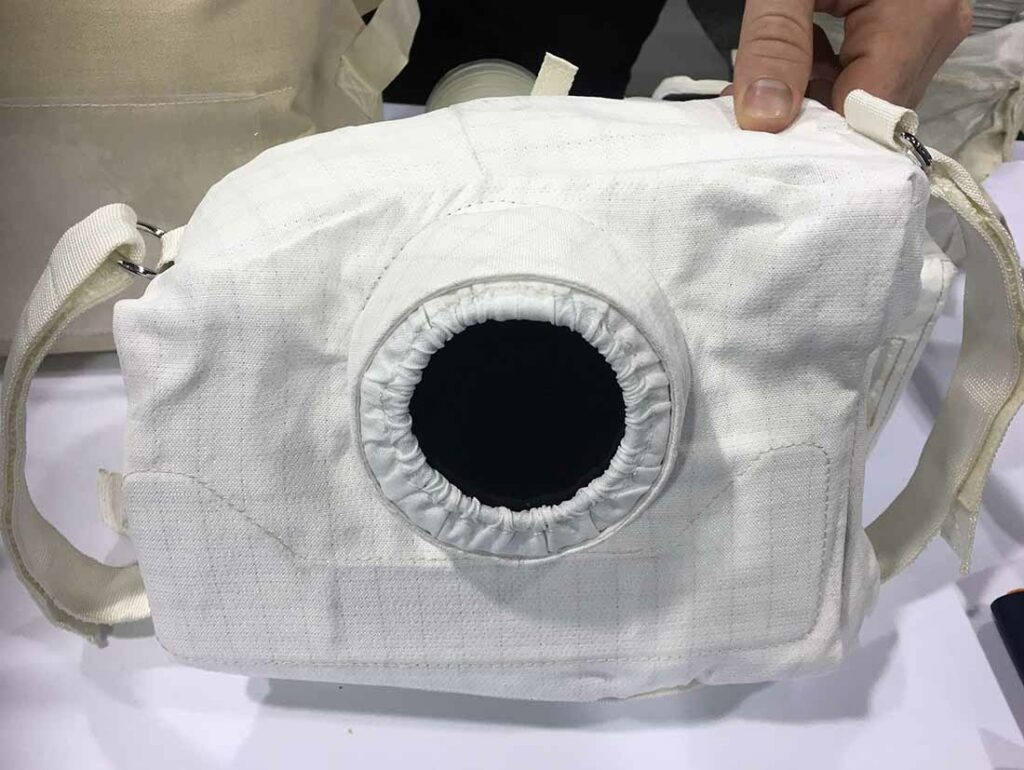

Photo courtesy of Marie O’Mahony

The topic that no one wanted to talk about last year proved the hot topic this year, though not necessarily with everyone agreeing.

There were two speakers addressing perfluoroalkyl substances (PFAS) this year, Elizabeth Denly, Vice President, PFAS Initiative Leader and Chemistry Director, TRC Companies and Frank Keohan, Senior Technology Manager at Bulger & O’Hearn. Denly described the many PFAS textile reporting categories and the information required by the United States’ Environmental Protection Agency (EPA) that includes chemical identity and structure, production, use, by products, exposure, disposal, health and environmental effects. The EPA is providing information and resources on its website, but the onus is firmly with the manufacturer or importer with historical reporting required from January 2011 to the end of December 2022 with no de minimis threshold. Facilities need to show documented due diligence in 2024 with complete reporting in the EPA’s Central Data Exchange (CDX) by January 2026.

The process of undertaking due diligence in this area is time consuming but Denly recommends not working with a regulator or a third party in order to avoid any potential errors. She also stresses the benefit of developing a strategy that allows stakeholders across the value chain to respond to regulatory drivers in a timely way.

Stain and water repellent fabrics are a key source of PFAS, from apparel to footwear, furniture and automotive interiors. In his presentation, Frank Keohan focused on the challenges in finding PFAS-free alternatives that can achieve the same level of functionality, with the most economical option, hydrophobic waxes, proving to be the least durable and require heat to regain repellency after wetting.

The U.S. Department of Defense (DOD) uses PFAS-based materials in a wide range of products from uniforms to backpacks, shelters and medical items. To eliminate the chemical from all products poses a significant standards, specification and procurement re-evaluation and the DOD has published a formal Request for Information (RFI) regarding the use of PFAS in textile-related defense materials. Brands in the consumer sector face the challenge of differing state regulations with some having no regulations and California banning the manufacture, sale or distribution of any textile containing in excess of 100 parts per million (ppm) on January 1, 2025.

Show Floor Innovations: From Fastening to Synthetic Leather

Fastenings proved to be a source of new innovations at AT EXPO 2024. Responding to consumer demand for waterproof zips for submersible and water sports applications. TRU Zip showcased their patented design of a sliding, airtight zipper. It is leakproof achieving a rating IP67 making it ideal for use in waterproof bag designs. Halco showcased an aramid loop tape with a stainless steel hook designed for high strength applications such as thermal blankets used to protect the outside of rockets as they enter Space. A new exhibitor at expo from Turkey, Şafak Technical Textil, introduced visitors to their range of synthetic leathers suited for applications such as high-end marine, automotive and aviation seating and trims. Sustainability is important to the 60-year-old company, with a unique water-based production process used in the manufacture of Corium, a polyurethane -impregnated (PU) microfiber produced in an array of colors with a pattern embossed to give a kid-leather or suede-like tactile quality.

Textile SME’s and AI: Balancing Time and Financial Costs with Benefits

AI has been the hottest topic of 2024, but while everyone acknowledges that it is here, for the majority of textile SMEs it is a period of learning and dipping a cautious toe in the water. Adam Penner’s presentation, “Unlocking AI: A Small Business Guide to Harnessing the Power of Artificial Intelligence,” was well attended as a campfire session.

He provided an overview and brief history, with a forthright discussion of the risks. There are privacy and ethical concerns around AI especially as it grows in the healthcare sector. It is also time and energy-intensive to train, as indicated by the moves in U.S. and Europe to open new and reopen nuclear power plants – most controversially the Three Mile Island nuclear power facility in Pennsylvania, which was the location of the most serious nuclear accident in American history.

Finally there is the issue of hallucinations where AI simply makes things up for no apparent reason other than part of its learning process. This latter point has not been highlighted nearly enough as it has the potential to inflict so much life-threatening, safety and reputational damage that will become increasingly difficult to detect. On the benefit side, it can certainly process and reduce large quantities of information into a more humanly manageable size and there are gains in real-time manufacturing diagnostics. The concerns are not new, and until they are addressed AI will continue to be viewed with caution.

Advanced Textiles Expo 2025 will be held November 5-7, 2025 in Indianapolis.

www.advancedtextilesexpo.com