In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant to our industry from manmade to natural to bio-based fibers, innovations in nonwoven, woven, braided and technical textiles, technologies for additives, bonding, coatings and polymers, and applications from apparel to hygiene to transportation, and more. Here we will post news stories relevant to textile fibers and their downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg at ken@ifj.com.

Most recent update: February 17, 2025

ANDRITZ Airlay Line for Nonwovens Production From Recycled Glass Wool Starts up at Revibat, France

International technology group ANDRITZ supplied and recently commissioned a state-of-the-art neXline airlay system for Revibat, France. This innovative line, inaugurated in February, enables the production of building insulation panels from glass wool waste that would otherwise be sent to landfills.

With the new ANDRITZ line, Revibat can now transform complex waste collected in the Paris region into valuable products. The patented process addresses two major challenges: giving a second life to insulation glass wool waste and reducing the carbon footprint across the entire production chain.

The line processes up to 1,500 kg of fiber per hour and is specifically designed to produce a unique nonwoven material, marking a significant step toward a circular economy in the insulation industry.

Nicolas Brousse, CEO of Revibat, states: “Our new ANDRITZ neXline airlay system represents a major milestone in our market as it enables us to start producing building insulation panels from glass wool waste. Our goal is to expand this solution across France, getting as close as possible to the waste and thereby minimizing our carbon footprint. Working with the experts at the ANDRITZ technical center in Cours has been a pleasure and essential for the development of this unique product.”

Revibat specializes in manufacturing construction materials from recycled building waste. Its mission has been to find a viable solution for the recycling of glass wool, a challenge that had previously remained unsolved. With a state-of-the-art laboratory, Revibat processes glass wool waste on an industrial scale, aiming to position itself as a key player in supporting eco-organizations in their efforts to collect, consolidate, and recover building waste and materials.

Fi-Tech, Inc. Welcomes Joe Bernard to Sales Team

Fi-Tech announced the addition of Joe Bernard to the sales team as Sales and Market Development Manager. In this role, Joe will be responsible for market development and customer management in the Northeast, Mid-West and Western USA in addition to other duties on our sales team.

Joe brings 15 years of manufacturing and sales experience in the textile and technical textile industries and holds a bachelor’s degree in Textile Technology from NC State University.

“We are thrilled to welcome Joe to our team,” said Managing Director, Jeffrey G. Bassett. “His vast experience and expertise in textile manufacturing and more recent sales and market development experience will enhance Fi-Tech’s service to our customers and European principals. Joe has a tremendous work ethic, an established reputation, and strong communication skills, allowing him to connect with and to serve our growing customer base.”

Joe Bernard also expressed excitement about joining Fi-Tech, saying, “I first worked with Fi-Tech on a project in 2014. The company and its staff have always been recognized as a provider of market leading products and services with the utmost professionalism. I experienced this firsthand in manufacturing and now I am excited to join their team.”

As Fi-Tech continues to expand, the addition of Joe reinforces the commitment to providing excellent service to our global customers.

Ontex Introduces Dreamshields® Technology in Baby Diapers

Ontex Group NV, a leading international developer and producer of personal care solutions, announced the commercial launch of its Dreamshields® technology for baby diapers. Offering superior performance, all-round leakage protection, and enhanced comfort, Dreamshields® ensures optimal dryness while prioritizing sustainability. The Dreamshields® technology is now available on shelf in several European markets in Europe and is being rolled out to more customers soon.

Laurent Nielly, President Europe at Ontex: “Dreamshields® is a key technology in our portfolio, offering a perfect balance of quality, affordability, and sustainability. By combining effective protection with a design that reduces CO2 emissions and plastic use, Dreamshields® meets the demands of today’s families while supporting our commitment to environmental responsibility. At Ontex, we focus on delivering relevant innovation that make everyday life easier for parents and families.”

Dreamshields® technology integrates a range of advanced features that benefit both parents and babies, enhancing comfort, protection, and ease of use. Panel scores show Dreamshields® performs great, especially when it comes to leakage protection. These innovations address both the needs of babies for comfort and the expectations of parents for reliability and sustainability:

- Unique channel design with gender-specific zones: enhances fast liquid flow across the entire core for superior absorption, ensuring babies stay dry and comfortable.

- SeconDRY® system: provides instant dryness by rapidly drawing moisture away from the skin, minimizing the risk of irritation

- Double-layer core with dual SAP (Super Absorbent Polymer): features two types of SAP, optimizing fast liquid attraction and solid retention for a lighter, more flexible diaper.

- 360° protection: combines front and back barriers with anti-leak cuffs, effectively preventing leaks and blow-outs in all directions.

- Heat release feature: promotes air circulation, maintaining fresh and healthy skin conditions to prevent discomfort and rashes.

- • High waist fit: offers a snug and stretchy fit that adapts to baby’s movements, ensuring comfort at all times.

DyStar Consolidates Charlotte Operations into Reidsville Site

DyStar, a leading specialty chemical company with a heritage of more than a century in product development and innovation, announced the sale of the property housing its manufacturing facility in Charlotte, North Carolina and subsequent consolidation of Charlotte production facility. As a result of the sale, the production facility, which produces performance chemicals, textiles and leather chemicals, will be integrated within DyStar LP in Reidsville, North Carolina.

The move of DyStar Carolina Chemical facility to DyStar LP in Reidsville is expected to take place over the next twelve months, with an expected completion by the end of 2025 or early 2026. The consolidated facility at DyStar LP, coupled with added capability from DyStar Carolina Chemical, will eventually drive DyStar Americas towards our goal of improving operational efficiency, reducing costs, and enhancing overall productivity. Customers can expect better proximity with an advanced infrastructure that is scalable for the future growth once the move is completed.

Unifi Shutters Massive Manufacturing Plant Near North Carolina’s HQ

Unifi, Inc., a leading innovator in recycled and synthetic yarn, announced that it will be transitioning yarn production out of its manufacturing facility in Madison, N.C., and placing the property for sale in calendar 2025. Production activities currently occurring at the Madison facility will be consolidated into UNIFI facilities in North and Central America.

“We are very grateful for the hard work, contributions and support from everyone involved with the Madison facility, including the community and employees, past and present. We will work closely with our employees and community to ensure the smoothest transition possible, and we are offering existing employees available opportunities at our other facilities in North Carolina,” said Eddie Ingle, chief executive officer of UNIFI, Inc.

UNIFI, Inc. is a global leader in fiber science and sustainable synthetic textiles. Using proprietary recycling technology, UNIFI is a pioneer in scaling the transformation of post-industrial and post-consumer waste into sustainable products. Through REPREVE, the world’s leading brand of traceable, recycled fiber and resin, UNIFI is changing the way industries think about the materials they use – and reuse. A vertically integrated manufacturer, the company has direct operations in the United States, Colombia, El Salvador,and Brazil, and sales offices all over the world. UNIFI envisions a future where circular and sustainable solutions are the only choice.

Grand Opening of the Fibroline USA Innovation Lab with Navis TubeTex

Leaders of Navis TubeTex, a U.S.-based leader in machinery manufacturing, and Fibroline, the French company that developed dry powder impregnation solutions, held the grand opening of an innovation center at Navis TubeTex’ headquarters in Lexington, North Carolina earlier this month.

Finalizing a strategic partnership in January 2024, Fibroline and Navis TubeTex launched a state-of-the-art laboratory that will help provide customers with support and cutting-edge technologies. This facility marks the beginning of a transformative journey in creating the next generation of advanced textiles, according to both companies. This laboratory will bring new expertise and resources to the U.S market for dry impregnation solutions.

Under terms of the partnership, the Innovation Center will promote Fibroline’s dry impregnation solutions in the U.S. market. Additionally, Navis TubeTex will be responsible for manufacturing and delivering the machinery required for U.S. customers, ensuring seamless access to Fibroline’s groundbreaking technology, according to Will Motchar, president & CEO of Navis TubeTex.

INDA, Nonwovens Industry Magazine Announce Finalists for the IDEA® Achievement Awards

INDA, the Association of the Nonwoven Fabrics Industry, in partnership with Nonwovens Industry magazine, announced the finalists for the 2025 IDEA® Achievement Awards. These awards recognize the most innovative new product introductions in the nonwovens and engineered materials industry since the last IDEA® event in 2022.

The IDEA® Achievement Awards celebrate excellence in product innovation across multiple categories, with nominees evaluated on creativity, novelty of approach, uniqueness, and technical sophistication. The awards will be presented during IDEA®25, the global event for nonwovens and engineered fabrics, taking place April 29-May 1, 2025, in Miami Beach, FL.

The Award Finalists are:

IDEA® Equipment Achievement Award

Dilo Systems GmbH – MicroPunch

GDM SPA – In Line Laminated Waistband

Oerlikon Neumag – hycuTEC

IDEA® Long-life Achievement Award

Egal Pads, Inc. – Egal™ Pads on a Roll

Hempitecture Inc. – PlantPanel

Magnera – Sontara® Home Compostable Bag

IDEA® Nonwoven Products Achievement Award

AHLSTROM – BioProtect™

Innovatec Microfibre Technology – InnovaWipe® Water-Soluble Nonwoven

Periodic Products, Inc. – MetalXtract® Filter Media

IDEA® Raw Materials Achievement Award

BASF SE – SAVIVA® B 800

OrganoClick AB – OC-Biobinder®

Woolchemy NZ Ltd – neweFibre

IDEA® Short-life Achievement Award

Egal Pads, Inc. – Egal™ Pads on a Roll

Hello Hazel, Inc. – Hazel® High & Dry Brief

Swoobie – Swoobie Bra Liner

IDEA® Sustainability Advancement Award

HIRO TECHNOLOGIES – The World’s First MycoDigestible™ Diapers

KINDCLOTH™ – PURA HEALTH Insect Repellent Water-Dissolvable Wipes

OrganoClick AB – OC-Biobinder®

These innovations reflect the industry’s commitment to advancing technology, sustainability, and performance in nonwoven materials. The Finalists will be voted on by industry professionals and the winners will be announced live at IDEA25.

Oerlikon Manmade Fibers Solutions Hosted Successful Technology Day 2025 in India

Oerlikon Manmade Fibers Solutions recently hosted its highly anticipated Innovation and Technology Day at the Deltin Hotel in Daman, India. The event attracted over 300 participants, including industry experts, partners, and stakeholders, who gathered to explore the latest advancements and trends in the manmade fibers industry in India.

The Innovation and Technology Day commenced with a warm welcome and introduction by Wolfgang Ernst, Chief Sales Officer (CSO) at Oerlikon Manmade Fibers Solutions, and Debabrata Ghosh, Head of Sales at Oerlikon Textile India. They provided an overview of the Indian market and its challenges. “The Indian textile industry, particularly the chemical fiber sector, is experiencing significant growth and transformation. This development is driven by increasing production capacities, strategic investments, and a shift in global consumption patterns”, said Ghosh. India’s production of manmade fibers (MMF) is robust, with annual outputs of 4.8 million tons of Polyester Filament Yarn (PFY), 1.7 million tons of Polyester Staple Fiber (PSF), 0.7 million tons of viscose, 0.2 million tons of Polyamide 6 (PA 6), and 25 thousand tons of acrylic. Additionally, the country boasts substantial capacities for PET bottles and films, growing at rates of 7% and 15% per annum, respectively. The Indian market is witnessing significant expansions in PTA (Purified Terephthalic Acid) capacity, with major projects underway by Indian Oil Corporation, GAIL, MCPI, Reliance Industries, and the Adani-Indorama joint venture. These expansions are set to increase the PTA capacity from the current 6.296 million tons to over 14 million tons by 2030.

Leigh Fibers Hits Significant Post-Consumer Textile Waste Milestone

Leigh Fibers Brownsville, Texas facility has recycled more than half a billion pounds of post-consumer textile waste since its startup in the late 1990s. Several years after its opening, the facility transitioned to recycling primarily post-consumer textile waste, serving industries within the United States and Mexico and hasn’t looked back since.

“We are proud to have been one of the first to engage the post-consumer textile waste issue and intend to continue to be a leader in this space”, said Steve Lister, Chief Financial Officer of Leigh Fibers. “Our end users encourage and embrace post-consumer content and nearly every brand and retailer in this country have sustainability goals, circularity goals, and a desire to keep their textile waste out of landfill.

John Ashford, Plant Manager of the Brownsville facility since the early 2000s said “It’s amazing to consider the impact we’ve had on the environment since transitioning to post-consumer processing in the early 2000s. Repurposing used clothing presents a lot of challenges and requires specialized expertise. I’m thankful for our dedicated staff that work closely with both the source of the waste as well as the end user of the fiber to develop solutions that meet the needs of both parties. I could not be prouder of what we have accomplished and look forward to what the future holds.”

Marine Shade Sunbrella Plus® Collection Expands Choices

Sunbrella announced the expansion of its Sunbrella Plus® marine shade offering to include 17 total color selections.

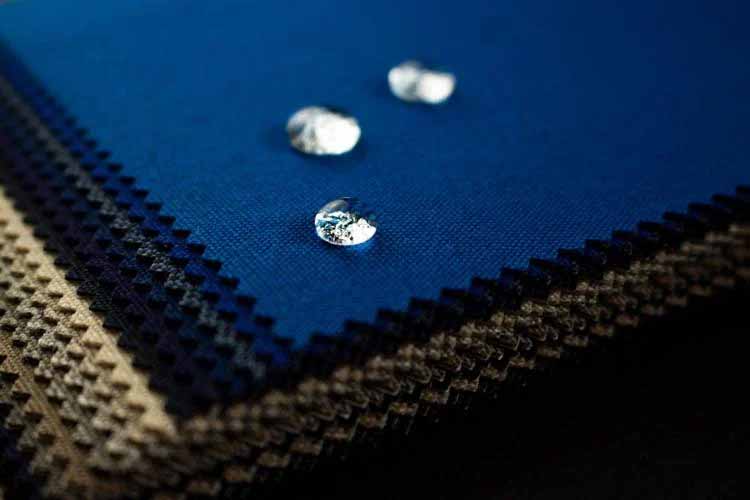

Sunbrella Plus features the benefits all Sunbrella fabrics are known for, including superior UV protection, weather-resistance and durability, while delivering enhanced water repellency thanks to its high-performing undercoating. The result is a highly versatile fabric that’s suitable for a variety of marine shade applications, including bimini tops, dodgers, protective covers and beyond.

“When you’re on the water, performance may reign supreme, but design takes the boating experience to a new level,” said Kate Carter, vice president and general manager of shade and marine at Sunbrella. “By broadening the color range of our Sunbrella Plus collection, we hope to give fabricators an enhanced toolkit for their marine boat top projects with fabrics that will thrive on the water time and time again.”

Vyld Launches World’s First Seaweed Tampon Across Germany

Vyld in Berlin, Germany has introduced the world’s first tampon made from seaweed, called the Kelpon, following successful certification. The profit-for-purpose company is rolling out the product across German restrooms through partnerships with employers, coworking spaces, gyms, and major event organizers.

“Product safety is our top priority, so we made sure to test the Kelpon well beyond the basal legal requirements,” emphasized Stefanie Malchow, R&D Lead Scientist at Vyld. Independent laboratory tests have confirmed the product’s safety, absence of harmful substances, and microbiome-friendliness.

The company has partnered with Periodically, Germany’s leading period product dispenser provider, to distribute Kelpons in office restrooms nationwide. “We highly value sustainability in all our products. Partnering with Vyld allows us to proudly offer one of the most environmentally friendly period product alternatives out there,” said Periodically founder Katharina Weißig.

Freudenberg to Present Battery Separator Solutions for Energy Storage Systems

Freudenberg Performance Materials will be showcasing its nonwoven battery separators at the International Battery Seminar in Orlando, Florida, from March 17-20, 2025. The leading manufacturer of technical textiles will present innovative materials that enable long-duration, high-performance and safe stationary energy storage systems.

Freudenberg will present its range of battery separators that increase the cycle-life, performance and safety of batteries for stationary energy storage systems, as well as batteries used in transportation, communications and computer systems. This includes nickel-cadmium, nickel-metal hydride, nickel-zinc, nickel-hydrogen, metal-air and lead-acid batteries plus many more.