In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant to our industry from manmade to natural to bio-based fibers, innovations in nonwoven, woven, braided and technical textiles, technologies for additives, bonding, coatings and polymers, and applications from apparel to hygiene to transportation, and more. Here we will post news stories relevant to textile fibers and their downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg at ken@ifj.com.

Most recent update: December 12, 2024

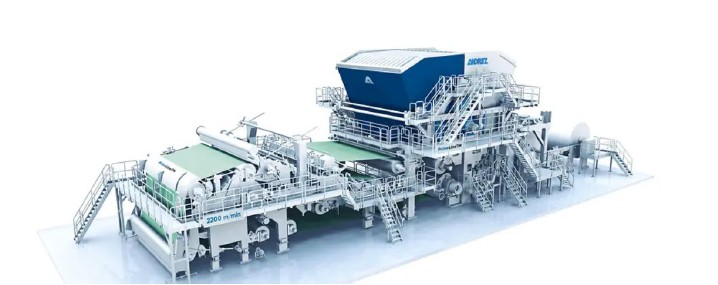

ANDRITZ to Supply Equipment to Juthor Paper, Kingdom of Saudi Arabia

International technology group ANDRITZ has received a major order for a tissue production line from Juthor Paper Manufacturing Co., part of Middle East Paper Co. (MEPCO) Group, Kingdom of Saudi Arabia. Start-up is scheduled for 2026. The value of the order will not be disclosed.

The line will be equipped with the latest ANDRITZ technologies from stock preparation to the reel to ensure low energy consumption and high product quality. The tissue machine will be one of the world’s fastest high-capacity machines, with a design speed of 2200 m/min and up to 5.47 m width at the reel. A comprehensive automation and digitalization package will contribute to high performance and operational efficiency.

Adel Alfar, Director Operations, Juthor Paper said: “We partnered with ANDRITZ because they are a high-end technology provider with a focus on optimized energy consumption for high-capacity and high-quality tissue production. Their commitment to support us in achieving our targets has convinced us.“

Textile Chemicals & Dyes Gets Separate Product Area at Techtextil

Techtextil will for the first time bundle the range of exhibitors in the field of Textile Chemicals & Dyes in an independent product area from 21 to 24 April 2026 in Frankfurt. The leading international trade fair for technical textiles and nonwovens is creating a central hub for suppliers and users. It emphasizes the increasing demand and relevance of Textile Chemicals & Dyes for the global textile industry.

Techtextil is responding to the growing demand from users and the requirements of suppliers for a centralized and concentrated industry platform for textile chemicals and dyes, and Techtextil is creating new synergies with this future bundling. Textile Chemicals & Dyes will be located in the same hall as Fibres and Yarns and Performance Apparel Textiles. Preliminary stages, suppliers and users will come together in the immediate proximity of each other. This makes it easier for them to communicate specific requirements and needs and find solutions more quickly.

Their growing importance of the segment is underlined by a 2021 analysis by the market research firm ‘MarketsandMarkets’. According to the study, the global market for textile chemicals is expected to grow to a volume of 33.1 billion US dollars by 2026. The study cites a number of factors as drivers of this growth, including the increasing demand for chemicals for the rapidly growing technical textiles market.

MMI Textiles Inc. Acquires Jason Mills, LLC

MMI Textiles Inc., a global diversified supplier of industrial and custom fabrics and textile components with military, tactical, medical, commercial, and apparel expertise, has acquired New Jersey-based manufacturer of knit textiles, Jason Mills, LLC. Effective January 2, 2025, the acquisition instantly expands the MMI Textiles product line, accelerating a key strategic growth initiative for the company.

“We have had the privilege of working with Jason Mills for many years and have tremendous respect for their approach to business, which aligns seamlessly with the culture we’ve built at MMI Textiles,” said Amy Bircher Bruyn, Founder, and CEO of MMI Textiles. “This acquisition marks an exciting milestone as we continue to grow and strengthen our position in the textile industry. We are eager to integrate their expertise, resources, and innovation to better serve our customers and address the evolving needs of the market.”

Founded in 1976, Jason Mills is known for its high-performance knits and operates in several major markets, including recreational trade, occupational safety, aeronautical, automotive and marine, healthcare, filtration, and industrial textiles.

Bally Ribbon Mills Highlights Broad Product Line of Medical Textiles and Fabrics

Bally Ribbon Mills (BRM), an industry leader in the design, development, and manufacture of highly specialized engineered woven fabrics, highlights its broad product line of medical textiles and fabrics ideal for use in cardiovascular, orthopedic, and dental prosthetic applications.

Tubular prosthesis of medical textiles can become one with the repaired vessel over time and can provide less invasive options than operations like open heart surgery. BRM’s woven seamless tubular materials for stent and knitted grafts offer solutions for aortic repair and endoluminal devices. Other BRM cardiovascular textiles facilitate Trans Aortic Valve Replacement and Aseptal Defect repair.

BRM’s medical textiles also include woven tapes and webbing in flat fabrics, or straight or bifurcated tubular structures. Monofilament materials used in blood filtration, aspirating devices, and bone marrow transplants are also available. For materials used in the manufacture of dental prosthetic devices, BRM offers braided composite substrates.

BRM works closely with major manufacturers to help support medical device development due to its capability to go from prototype into full-scale production.

BRM manufactures medical textiles in a certified clean room to ensure cleanliness and quality and maintains the rigorous ISO 13485:2016 certification for the design and manufacture of medical devices. Additionally, medical textiles engineers, prototype weavers, and braiders at BRM work on a confidential basis to protect the intellectual property of customers.

MoistTech Highlights IR3000 Series Moisture Sensors for Textile and Nonwoven

MoistTech Corp., a leader in moisture measurement and control, is highlighting its cutting-edge IR3000 series moisture sensors for the textile and nonwoven industries. These state-of-the-art sensors, featuring Near Infrared (NIR) technology, offer unparalleled accuracy and reliability in moisture analysis, significantly enhancing product quality, productivity, and energy efficiency throughout the textile manufacturing process.

The IR3000 series sensors provide instant, continuous moisture measurement, allowing textile manufacturers to maintain precise control over moisture content from fiber production to finished fabrics. This capability is crucial for ensuring optimal product quality and manufacturing efficiency as water can greatly impact textile production lines. Many fabrics rapidly absorb and release moisture due to their hygroscopic nature. Consequently, the water context of a fabric greatly affects its physical properties, including length, dimension, strength, elasticity, and electrical resistance.

One of the key advantages of the IR3000 series is its ability to measure moisture in a wide range of materials, including natural fibers like cotton and wool, synthetic fibers, and blended fabrics. In industries where mold is a concern, particularly in the cotton ginning sector, the IR3000 effectively maintains moisture content below 8%, thereby preventing losses caused by mold.

The IR3000’s non-contact design allows for continuous operation without interfering with the manufacturing process, minimizing contamination and maintenance requirements. This feature is particularly beneficial in high-speed textile production environments where continuous monitoring is essential.

Milliken & Company Achieves EcoVadis Gold Rating

Global diversified manufacturer Milliken & Company announced that it earned a gold rating on its 2024 EcoVadis assessment. EcoVadis provides trusted business sustainability ratings for more than 130,000 organizations representing more than 220 industries. Milliken’s 2024 EcoVadis score, assessed across its chemical, textile, flooring and healthcare operations, again places the company in the top 5% of organizations rated. This is the third consecutive year that Milliken has earned a gold rating from EcoVadis.

“We are honored to receive a gold rating from EcoVadis once again,” said Halsey Cook, president and CEO at Milliken. “This achievement reflects our unwavering commitment to sustainability and the significant strides we have made on our journey. Our dedication to promoting transparency and innovation is what drives us to continually improve and reach new heights in our sustainability efforts.”

Mark Ushpol Appointed EVP, Americas Business Area at Suominen

Mark Ushpol has been appointed Executive Vice President, Americas business area at Suominen. He will be a member of Suominen’s Executive Management Team and report to President and CEO Tommi Björnman. Ushpol will start in his new position on January 6, 2025.

Ushpol joins Suominen from Ahlstrom, where he worked as Executive Vice President of the Food & Consumer Packaging division and as a member of the Executive Management Team.

“Mark has a strong experience in leading industrial business and operations. He also has industry knowledge and proven record in successfully executing company goals. I am sure he will be a valued member in our Executive Management Team and support us in our journey towards profitable growth,” said Tommi Björnman, President and CEO of Suominen.

Microban Launches New Nature-Inspired Odor Control Technology

Microban International, a global leader in odor control technology, recently announced Freshology™, a patent-pending, nature-inspired* solution for combatting odors, at ISPO Munich, December 3–5, 2024.

The new technology offers advanced performance by neutralizing a wide range of odors, keeping textiles fresher for longer. It meets GB/T 33610 and ISO 17299 testing standards for four of the most common odorants: isovaleric acid (IVA), acetic acid (HOAc), ammonia (NH3) and nonenal, making it a groundbreaking solution for tackling unpleasant smells.

“Freshology was developed by balancing and optimizing performance between different chemical profiles,” said Ryan Scott, senior product development chemist at Microban. “The technology offers key advantages for consumers: it effectively traps a wide range of body odors, unlike products that target only one specific odorant. Additionally, it improves moisture management and enhances the softness and feel of treated fabrics.”

Freshology is integrated into synthetic materials such as polyester, nylon and spandex during the finishing process and captures odors until the fabric is washed. During washing, the technology releases the trapped odorants, renewing the product’s effectiveness. It is nonionic, which allows for the incorporation of additional technologies or treatments during manufacturing without compromising the integrity of the product.

Gildan Rings the Opening Bell on the New York Stock Exchange

Gildan Activewear Inc. announced first week of December that its President and CEO, Glenn J. Chamandy, rang the Opening Bell® on the New York Stock Exchange (NYSE) to mark the Company’s 40th anniversary as well as its 25th anniversary of being listed on the NYSE. He was joined on the podium by members of the Company’s senior leadership team, as well as Michael Kneeland, Chairman of the Board, and Mélanie Kau, Board member, Chair of the Corporate Governance and Social Responsibility committee.

Gildan has a forty-year history anchored by strong long-term operating results driven by an outstanding employee base. The Company sets itself apart from the industry, by taking great pride in manufacturing its products from start to finish as one of the largest domestic consumers of U.S. cotton, leveraging a vertically integrated manufacturing model and, an expertise and scale built over the years. Since the beginning, Gildan has demonstrated that while its products matter, how they are made matters even more: from caring for workers’ safety, wellness and livelihood, to supporting meaningful community actions and championing innovative environmental initiatives within its operations, among other initiatives.

The Opening Bell® Ceremony took place at 9:30 a.m. EDT on Monday, December 2nd, 2024.

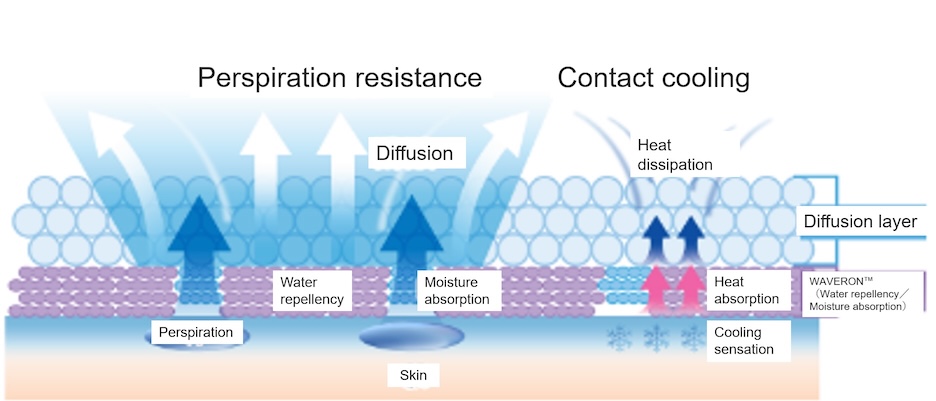

Teijin Frontier Develops Next-Generation Comfort Material for Active and Functional Apparel

Teijin Frontier Co., Ltd., announced that it has developed a next-generation comfort material that uniquely combines contact cooling functionality with sweat stickiness prevention. The new material features a dual-layer, knit structure where the inner layer alternates Teijin Frontier’s newly developed hydrophobic WAVERON™ yarn and conventional hydrophilic WAVERON™ yarn. The hydrophilic yarn absorbs perspiration, while the hydrophobic yarn prevents it from adhering to the skin to keep the skin dry. The outer layer disperses absorbed perspiration to the outside.

Teijin Frontier plans to promote and sell this next-generation comfort material as a desirable fabric for the 2026 spring/summer sports and outdoor apparel season, in both domestic and international markets. In advance of that season, the company aims to sell 100,000 meters of the material. Subsequently, it will expand into functional apparel such as fashion clothing. By fiscal 2028, Teijin Frontier expects to sell 1 million meters of this next-generation comfort material per year.

ANDRITZ Receives Engineering Order for Landmark Textile Recycling Plant from Circ

International technology group ANDRITZ has received an engineering order from US textile recycling innovator Circ in anticipation of its first large-scale textile recycling plant. The plant will be the first to recover cotton and polyester from blended textile waste.

Conor Hartman, Chief Operating Officer at Circ, said: “We remain excited about this continued collaboration with ANDRITZ. Together, we will commercialize Circ’s innovative recycling process and take another step towards a truly circular fashion industry. With its expertise in engineering and building large-scale process equipment, ANDRITZ is the right partner to help us transform textile waste into recycled fibers on an industrial level.”

The majority of fashion waste consists of polyester-cotton blends, which poses a significant challenge to achieving greater circularity. In particular, the separation of cellulosic and synthetic fibers from textile waste has been a major obstacle. Circ’s innovative recycling process can break down polycotton textile waste into its original components – polyester and cotton. The forthcoming plant will process 200 tons of textile waste per day, allowing cotton to be recycled for lyocell production and polyester to be reused for polyester production. This will reduce the need for virgin raw materials.

ANDRITZ has been successfully conducting trials for Circ at the ANDRITZ Fiber R&D Center in Springfield, Ohio, USA, for several years. The successful partnership and recent developments have led to the decision to expand this cooperation.

Circ® is a pioneering company focused on sustainable solutions for the fashion industry. By converting fashion waste into reusable raw materials for fabrics, Circ reduces the need for petroleum and natural resources. The company’s mission is to build a truly circular economy to protect the planet from the cost of clothing.