Innovation and Leadership are the Ultimate Key to Create a Cleaner World through Filtration Solutions

In the nonwovens and filtration industry, there is a desire to create more sustainable materials that reduce environmental impact, especially given that filtration products are consumables with fixed lifespans. They are also notoriously difficult to recycle. As a result, efforts to support the circular economy remain challenging.

The industry recognizes the changing needs of the planet and the shifting desires of people, as it navigates an increase in environmental awareness, greater demand for sustainable practices and a need for innovative solutions. At Hollingsworth & Vose, we work diligently to lead by example in taking responsibility for developing products with superior performance and reduced impact, innovating for more than 200 years.

While investments are being made in the industry on research and development around the use of more sustainable fibers and through earth-friendly supply chains, the issue remains that scalable and affordable solutions take time, significant financial resources and require commercial acceptance. Given the urgency of the problems facing the planet, there are ways for manufacturers and suppliers to make an immediate dent in environmental outcomes beyond focusing on greener materials and the supply chains that go into their filtration products.

Consider the matter of energy, for example. According to the Environmental Protection Agency, the energy sector is the largest emitter of greenhouse gases into the atmosphere, contributing to climate change1. Globally, buildings are responsible for around 37% of carbon emissions and 34% of energy use2. In most commercial buildings, the HVAC system is the primary consumer of energy. The pressure drop of air filters can greatly impact how hard HVAC fans must work, which impacts those energy outcomes. Filter media technology that promotes reduced energy burdens without sacrificing performance – while keeping occupants and downstream assets safe – can lead to real gains in the decarbonization of buildings.

This new synthetic air filter media has been developed especially for use during rainy seasons and in humid conditions.

Here are three areas that H&V has demonstrated leadership to innovate filtration for the future. They are an example of developing solutions that consider the demands of the marketplace.

IAQ – A Winning Combination for Data Centers

Have you used Google search today? If so, Google estimates that your search required as much energy as illuminating a 60-watt light bulb for 17 seconds and emitted 0.2 grams of CO23. Given the head-turning statistic that 90% percent of the world’s data was created in the last two years, and that every two years the volume of data across the world doubles in size4, one can imagine the extraordinary energy and associated greenhouse emissions that come with the data territory.

In fact, data centers have the highest energy usage density among all building types, and they are being built at a staggering rate. Bill Vass, vice president of engineering at Amazon Web Services, was recently quoted as saying the world adds a new data center every three days.5

In the midst of ever-increasing data loads and the growth of technology like artificial intelligence, data centers will continue to have an outsized impact on the amount of energy they consume versus other buildings. They will also continue to require significant energy for cooling, which helps prevent devastating downtime. However, some of that energy use can be offset through decisions made at the HVAC level.

That’s because data centers use a metric called Power Usage Effectiveness (PUE), which is designed to measure and isolate where and how improvements can be made in the efficiency performance of the electrical and mechanical infrastructure of the building. A major contributor to energy expenditure in data centers is the cooling system. By reducing fan energy, largely impacted by the pressure drop of the filters in the system, a more beneficial PUE ratio can be achieved.

H&V has developed a proprietary synthetic media called NanoWave®, which can achieve extraordinarily low pressure drop results at superior dust-holding capacity (DHC) compared to traditional synthetic medias and glass mat. This energy-efficient media is increasingly being deployed in data center filters to help improve the PUE ratio. To ensure our NanoWave® solutions are contributing to positive sustainability outcomes, a third-party review of our material by Sustainserv concluded that NanoWave® emits 32 times less carbon and generates a savings of -326 kgs CO2e per filter use from cradle-to-gate compared to other standard glass mat media. That equates to less energy for increased performance – a winning combination to support data center decarbonization efforts through reduced energy usage.

VIAQ – The Heart of the (Filter Media) Matter

In the automotive sector, cabin air filters protect drivers and passengers from harmful pollutants such as dust, debris, bacteria, gases, volatile organic compounds and allergens. Even an hour or two riding in a vehicle can expose people to dangerous levels of air pollution, which can lead to serious diseases. That is why good vehicle interior air quality (VIAQ) is essential in all types of vehicles, from cars and commercial trucks to buses, trains, agricultural vehicles and even airplanes. At the heart of VIAQ and cabin air filtration is the filter media, which largely determines the performance and reliability of the filter.

There are different approaches and perspectives when talking about creating more sustainable filtration solutions for the VIAQ segment. One of the possibilities is exploring the filtration properties of cabin air filters – for example, extending the lifetime of filters by increasing their efficiency and dust-holding capacity. Another way to make a cabin air filter more sustainable is to improve its energy usage by providing filter media with the lowest possible pressure drop. Considering recycled or biobased raw materials, lowering transportation cost, and keeping operational costs minimal are certainly ways to make cabin air filters more sustainable.

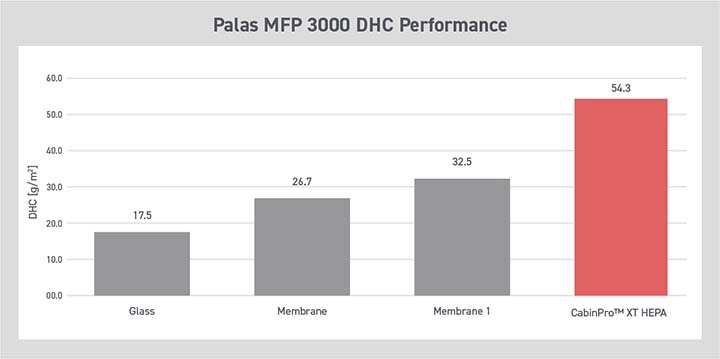

H&V took the extended media approach and has developed a patented high-performance filtration solution, CabinPro™ XT HEPA cabin air filter media. This highly stable HEPA efficiency filter media offers best-in-class protection against particulate contamination for vehicle occupants. Internal tests have shown it provides a much higher DHC than other similar products on the market, meaning filters using CabinPro™ XT HEPA filter media have a much longer lifespan.

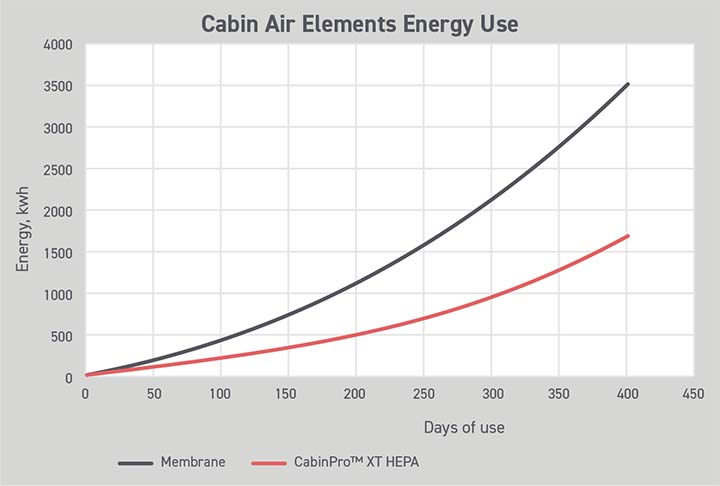

If the final application has a dedicated prefilter upstream of the filter made of CabinPro™ XT HEPA filter media, automotive OEMs and AC manufacturers can reverse the orientation of the filter to further reduce pressure drop and maximize energy savings.

Over its lifetime, CabinPro™ XT HEPA filter media shows a lower pressure drop compared to other products on the market, even the ones having a lower initial pressure drop. This is significant for the overall energy consumption over the lifetime of a filter.

In addition, CabinPro™ XT HEPA is made without the use of per- and polyfluoroalkyl substances (PFAS), which are coming under increased regulatory and environmental scrutiny. Therefore, the media not only improves VIAQ but also minimizes the environmental impact of the filters after their service life.

HD Air – Heavy-Duty Fuel Savings

Air filtration systems in heavy-duty vehicles are responsible for the filtration of dust particles in the air, which ensures clean air for the fuel combustion in internal combustion engines (ICE). The filtration performance of the air filtration system, including air resistance, efficiency, and service interval, mainly depends on the filtration media in the element. H&V has designed and produced multiple

filtration media with exceptional performance for these kinds of heavy-duty applications.

In recent years, truck manufacturers have begun to highlight the fuel combustion efficiency of their engines. OEMs have also promised to become carbon neutral and to begin cutting CO2 emissions within the next 10 years. Air filtration systems plays a key role combustion efficiency. Researchers have revealed that insufficient air provision can cause incomplete combustion in the engine, which leads to a lack of power, excessive fuel consumption and toxic emissions.

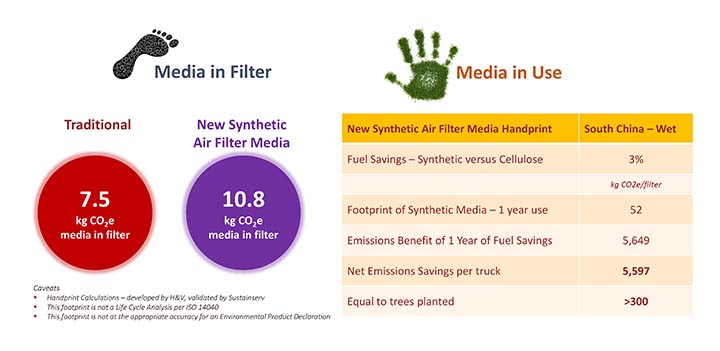

One of H&V’s core product lines has historically been cellulose-based heavy-duty air media, used to protect engines in on- and off-road transportation and agricultural equipment. As a continual innovator with a focus on sustainability, researchers developed a next-generation synthetic media, which enables fuel saving in use. This new synthetic air filter media has been developed especially for use during rainy seasons and in humid conditions. Its nonwoven fiber composition ensures stable air flow from the filtration system, compared to the decreased air flow that comes when using regular cellulose media.

These fuel savings were proven through a set of rigorous field studies in the north and south of China. While the cellulose media had half of the carbon footprint of the synthetic media, the synthetic media enabled emissions reduction (via annual fuel savings) of between 43 and more than 130 times the footprint, with one long haul truck saving more than 5MT CO2 emission per year – the same impact of planting 300 trees.

Lead By Example

One company alone cannot make the outsized difference necessary. H&V is proud to prioritize our sustainable activities and product solutions to ensure we can support our industry for the next 200 years, as we navigate the issues at the forefront of our culture. Yet, it will certainly take a consortium of companies and stakeholders in the nonwovens and filtration sector to make a meaningful and measurable global impact. We invite others to work alongside us in our mission to create a cleaner, healthier, more sustainable world.

References:

1Climate Change Impacts on Energy | US EPA

22022 Global Status Report for Buildings and Construction | UNEP – UN Environment Programme

3Energy Hogs: Can World’s Huge Data Centers Be Made More Efficient? – Yale E360

4Data Statistics (2024) – How much data is there in the world? (rivery.io)

5Big Tech’s Latest Obsession Is Finding Enough Energy (msn.com)